I still do not understand what the original fault with the vehicle was. And have you replaced lock cylinder or ignition switch?

IGNITION SWITCH

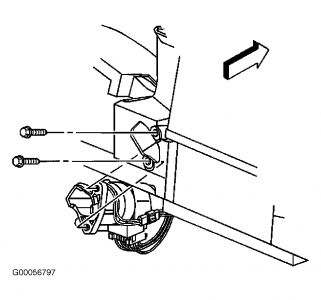

Removal

NOTE:Door, trunk and ignition are operated by one key. If procedure requires ignition switch lock cylinder to be replaced, new ignition switch lock cylinder should be recoded to old key.

NOTE:Passlock(tm) sensor is an integral part of ignition switch assembly

VEHICLE THEFT DETERRENT (VTD) SYSTEM

The anti-theft system has been incorporated into Body Control Module (BCM). Anti-theft system prevents vehicle operation if correct key is not used in order to start vehicle. Ignition key turns ignition lock cylinder. Cylinder rotation produces an analog voltage code in Passlock(tm) sensor. This voltage code is received by BCM. BCM compares voltage code to previously learned voltage code. If codes match, a class 2 message is sent from BCM to Powertrain Control Module (PCM). Message enables fuel injectors and crank relay.

The design of Passlock(tm) system is to prevent vehicle theft by disabling engine unless ignition lock cylinder rotates properly by engaging correct ignition key. System is similar in concept to passkey system. However, Passlock(tm) system eliminates need for a key mounted resistor pellet. Components of Passlock(tm) system are as follows:

Ignition lock cylinder

Ignition switch

Passlock(tm) sensor

Body Control Module (BCM)

SECURITY indicator

Powertrain Control Module (PCM)

Ignition Lock Cylinder and Housing

The Passlock(tm) sensor and ignition lock cylinder are one assembly. Passlock(tm) sensor is separate from key and lock cylinder. Key and lock cylinder work together in order to determine if proper ignition key was used to start vehicle.

In event of an open Class 2 serial data line between BCM and PCM, vehicle will become fail-enabled if PCM has already received password from BCM for that ignition cycle (engine running). When this happens, SECURITY indicator will illuminating PCM will become fail-enabled for future ignition cycles.

If a failure in Class 2 serial data line occurs before ignition cycle, when PCM is not fail-enabled, PCM will never receive a valid password in order to enable fuel injectors and crank relay and vehicle will not start.

Ignition Switch

The electrical switching portion of ignition lock cylinder assembly is separate from key and lock cylinder. Electrical switch portion and key and lock cylinder synchronize and work in conjunction through action of mechanical assembly between two components.

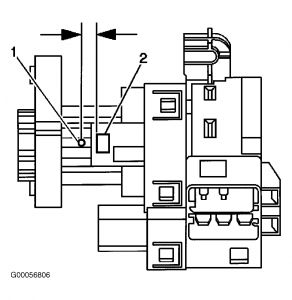

Passlock(tm) Sensor

The Passlock(tm) sensor contains 2 hall effect sensors. Tamper hall effect sensor is on top. Security hall effect sensor is under tamper hall effect sensor. Both hall effect sensors monitor magnet of lock cylinder through an opening. Tamper hall effect sensor is physically placed on top of security hall effect sensor. This arrangement enables tamper hall effect sensor to engage first if an intruder attempts to bypass Passlock(tm) sensor by placing a large magnet around that area of steering column. There is a tamper resistor inside Passlock(tm) sensor in order to help prevent tamper to system. Passlock(tm) equipped vehicles have a selection of 10 different security resistors ranging from 0.5K ohms to 13.6K ohms. Installing one of the security resistors inside Passlock(tm) sensor will generate a unique Passlock(tm) code. All 10 combinations of Passlock(tm) sensor have same part number.

Body Control Module

The Body Control Module (BCM) contains anti-theft system logic. BCM reads Passlock(tm) data from Passlock(tm) sensor. If Passlock(tm) data is correct, BCM will send a class 2 message to PCM to enable fuel injectors and crank relay.

During tamper mode vehicle may start. Vehicle will then stall. If BCM receives wrong Passlock(tm) data, VTD system will immediately go into tamper mode. Tamper mode will lock-out vehicle fuel injectors and crank relay for 10 minutes. SECURITY indicator will flash while VTD is in tamper mode.

If Passlock(tm) sensor sends a correct password to BCM when ignition is in RUN position, BCM will send a fuel enable and crank relay enable signal to PCM.

SECURITY indicator

The SECURITY indicator appears on message center inside instrument cluster. If SECURITY indicator flashes or if SECURITY indicator illuminates continuously during vehicle operation, refer to system diagnosis.

Powertrain Control Module (PCM)

The PCM communicates with BCM over Class 2 serial data line. When BCM determines an incorrect password, it sends a Class 2 serial data password to PCM in order to disable crank relay and fuel injection system. If BCM receives expected voltage from Passlock(tm) sensor, BCM sends a class 2 serial data password to PCM in order to enable crank relay and fuel injection system. PCM then allows vehicle to start normally.

Fuel Lockout Cycle

The Passlock(tm) system has a lockout cycle of approximately 10 minutes. Once vehicle is in lockout cycle, vehicle remains in lockout cycle for 10 minutes, even if ignition switch is turned from RUN position to OFF position.

The Passlock(tm) system uses lockout cycle in order to synchronize all of Passlock(tm) components when any Passlock(tm) related part is replaced. Passlock(tm) system requires 3 consecutive lockout cycles in order to complete 30 minute learn procedure for a changed component.

Changing Passlock(tm) Components

The design of Passlock(tm) system is to prevent theft even if various theft deterrent parts change. Parts that can no longer be changed without possibility of going into a tamper mode are Passlock(tm) sensor, BCM and PCM.

If you replace any of these parts, vehicle may not start for 10 minutes. This is long tamper mode. If this occurs, system must go through a long tamper mode cycle. During this time SECURITY indicator will be flashing for a full 10 minutes and DTC B3031 will be set. BCM and PCM require a full 10 minutes in order to complete a learn cycle. Ignition switch must remain in RUN position until SECURITY indicator stops flashing. You will need to repeat cycle if ignition switch does not remain in RUN position. When replacing any listed parts, program Passlock(tm) system. See PASSLOCK(tm) SYSTEM under PROGRAMMING.

The design of Passlock(tm) system is to prevent vehicle operation if proper ignition key is not used in order to start vehicle. Mechanical key, in normal operation, will turn ignition lock cylinder. Passlock(tm) sensor monitoring position of lock cylinder will relay Passlock(tm) data to Body Control Module (BCM). BCM will determine validity of Passlock(tm) data. BCM will send a password to Powertrain Control Module (PCM). When PCM receives correct password PCM allows crank relay and fuel injectors to operate normally. Passlock(tm) system requires PCM and BCM to communicate various functions in order to operate. These functions transmit over class 2 serial data line.

ADDING OR REPLACING KEYS

The ignition lock cylinder and keys do not contain any coded electronic components. Lock cylinder housing contains coded electronic components. Changing an ignition lock cylinder or adding a key is a purely mechanical process which does not affect vehicle anti-theft system. To add or replace a key, simply cut a new key to match existing one. If no keys are available, lock cylinder must be changed. To change lock cylinder, simply replace existing lock cylinder with one of same type.

Monday, August 24th, 2020 AT 1:58 PM