Radiators consist of a few basic parts, two tanks and the core. The radiator "tanks" located on the sides or top and bottom are used to attach upper and lower coolant hoses. Vehicles that have tow options will sometimes incorporate an engine oil cooler into the radiator to help keep the engine temperatures at a safe level. Radiators come with different amounts of these tubes or “rows” as they are called in the industry to support various applications. Old radiators are recycled cutting down on heavy metals and environmental impacts.

History

Through the years materials used in the construction of a radiator have changed dramatically. Older vehicles used a heavy brass construction, while newer vehicles use an aluminum core and plastic tanks. Brass radiators worked well for years, but material costs and the environmental impact of the materials used to solder them together (lead mixtures) have phased them out, newer lighter designs are clamped together with rubber gaskets. Radiators for performance applications are usually custom fabricated to the application and are made of aluminum tanks and cores to withstand the severe vibrations and heat.

Maintenance

Use a flashlight to look for leaks where the tanks attach to the core (center) of the radiator; this is a common place for failure. Radiator tanks have a tendency to crack or become brittle and break. Radiators as with all automotive replacement parts come in a vast array of quality levels. A cheaper radiator will consist of thinner plastic tanks and aluminum core which will fail prematurely. If a radiator is leaking or plugged and needs to be replaced, this can usually be performed with a minimum amount of tools.

Let's Jump In!

An automotive radiator is at the heart of a vehicles cooling system and keep

an internal combustion engine from overheating avoiding catastrophic failure. Radiators

are manufactured in all shapes and sizes, depending on the space constraints and

requirements of the vehicle's design. A large vehicle such as a truck will have

a multiple-row high capacity radiator while a small vehicle will have a much smaller

radiator with less capacity.

There are two different styles of radiators used in the automotive industry;

cross or top flow. A top flow radiator takes hot coolant and cools it as it flows

downward. All radiators have small coolant tubes which have fins attached to them

that act as heat syncs and dissipate heat through convection and air flow through

the front of the vehicle or a fan pulling air through the radiator. The more fins

per square inch, the more efficient the radiator is at dissipating the heat and

keeping the engine cool.

A radiator cap is used to add coolant to the system and it provides an inspection

port for maintenance purposes.

An overflow tube is used to transfer expanding coolant into the coolant reservoir,

and then allowing the coolant to transfer back into the radiator once the engine

has cooled down.

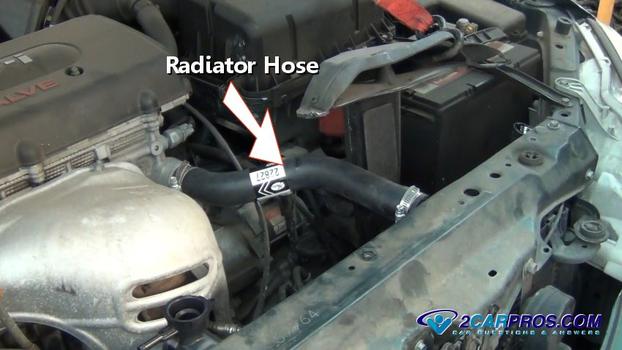

An upper and lower radiator hose is used to transfer engine coolant to radiator

and back into the engine.

When adding coolant use a small funnel to avoid spillage. (Note: Always check

coolant levels when the engine is cold.)

A pressure cap is used to maintain between 16 and 18 psi within the system to

further aid the cooling systems performance. For every two pounds of pressure inside

the system the boiling point of the coolant raises one degree.

Vehicles equipped with an automatic transmission use transmission fluid cooling

hoses (inbound - outbound) that connect to the fluid cooler built inside of the

radiator.

Questions?

Our certified technicians are ready to answer radiator questions for free. We hope you saved money and learned from this guide. We are creating a full set of car repair guides. Please subscribe to our 2CarPros YouTube channel and check back often for new videos which are uploaded regularly.