There's no practical way to bypass the compressor because that would also eliminate the water pump. You would have to design and build some type of substitute pulley and mounting bracket, but I wouldn't trust that any further than you're willing to walk back home.

The only way the AC pulley will cause the belt to be thrown off is if the bearings inside it are worn or broken apart. You'll see that as severe wobbling when you spin it by hand. If those bearings were to lock up, that would simply cause the compressor to run all the time the engine is running. It would never cycle off periodically. If the compressor itself is locked up, you'll hear horrendous screeching when the clutch cycles on. The belt might slip over that pulley, but more likely the clutch will slip and get real hot. That would only occur when the AC or defrost functions are selected. To prevent the clutch from engaging a locked-up compressor, just unplug the two-wire connector behind the clutch / pulley assembly. You could also unplug the compressor relay in the under-hood fuse box, but the Engine Computer will see that and set a diagnostic fault code. That should not be an emissions-related problem, so it shouldn't turn on the Check Engine light, but if it does, since it will always be on, you'll never know if a potentially more serious defect is detected. Often minor defects turn into expensive problems if they're unwittingly ignored by a Check Engine light that's always on.

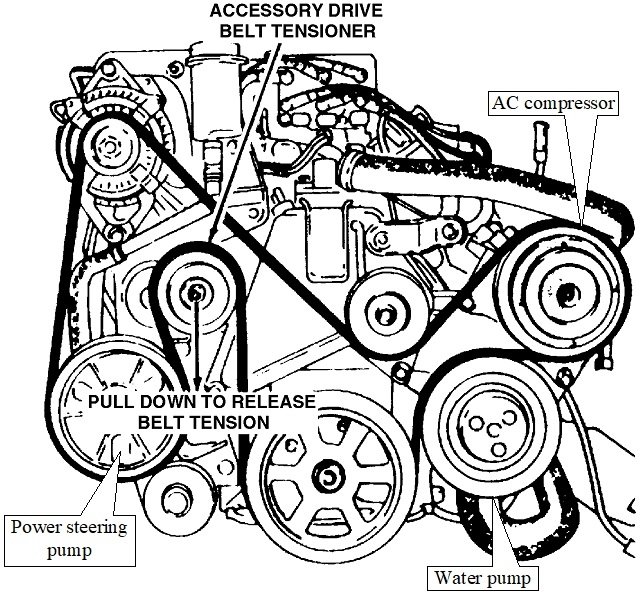

By far the more common suspect is the belt tensioner, as your seller suggested. They rarely lose their tension on the belt. It's more common for the pivot to wear, then the arm and pulley sits at an angle. It's no longer perfectly parallel to the belt and the other pulleys. When that is not too severe yet, that will set up a belt squeal because the belt is sliding across that pulley as it goes around it or the next one in line.

The way to identify a worn tensioner assembly is with the new belt installed and the engine running, sight down from on top, through all of the pulleys. You should not see the belt peeking out to one side on any of the lower pulleys. When the tensioner is worn, you'll typically see as much as 1/8" of the belt, or about one groove worth, out further compared to where it has just left the top of the alternator pulley. That is proof of the wear, and that will allow the assembly to vibrate at certain engine speeds. That's what throws the belt off, then it can get tangled in any of the other pulleys.

There's another bigger problem with disabling the AC system in any way. If you replace or just disconnect the battery for any other service, the HVAC Computer will lose its memory and will have to be recalibrated. Until that is done, the six yellow LEDs in the switches will flash continuously and you'll have limited control over the functions.

There's two parts to the recalibration. The first part involves pressing two of the switches at the same time until two of the lights flash alternately. At that time, the computer runs the mode and temperature doors through their ranges, and takes readings from all of the position sensors and puts them in memory. That test is real easy to pass on the first try.

It's the second test, the "cool-down" test that can be very frustrating. If you follow the instructions in the service manual, this test will fail every time. I can post the instructions that worked for me, if necessary, but part of it requires the evaporator in the dash to drop by at least 80 degrees within 20 seconds to calibrate the temperature sensor. That can never happen if the AC system isn't working properly.

Once you know about this need to recalibrate, this can all be avoided if you use a memory saver device before disconnecting the battery. This is becoming more and more necessary on newer models, especially with VWs, GMs, BMWs, Hondas, and Audis. On many of those, the engines won't even start after simply disconnecting the battery. It's also common for the radios to lock up, requiring a trip to the dealership to unlock them.

Image (Click to make bigger)

Tuesday, April 27th, 2021 AT 3:54 PM