Once I posted my reply, this became a private conversation between the two of us, although some of the other experts might add some comments. Be aware that due to a house fire I do not have internet access at home. I drive twenty one miles each night to answer questions, so do not panic if I do not reply right away.

If you try to replace a wiring harness, you will find it is a really huge mess that runs all over the front of the vehicle, and new ones are horribly expensive because they are hand-made. The only time we replace an entire harness is when that is mandated by the manufacturer and the vehicle is under warranty. For everything else, we locate the cause of the problem, then fix it. Some people run new wires, but that is also not desirable. You want to know exactly why that wire developed a problem because it could affect other wires in that harness too. For example, if a harness is laying on the sharp edge of a metal bracket, one wire will rub through first and cause a problem. If that cause is not located, how long will it be before the next one rubs through, and will it be for a circuit that leaves you walking along the highway? Harnesses can also rub back on forth on the body as the engine rocks back and forth between accelerating and braking. I have seen one wire shorting intermittently for the back-up lights, and blowing the fuse repeatedly, and when found, there were another half dozen wires already rubbed bare, but not shorting out, yet. That replacement harness cost over $1,500.00, so obviously we fixed the old one.

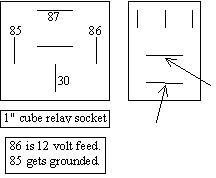

How is your understanding of electrical theory? If it is not good, start with a visual inspection of the terminals in the connectors. Look for signs of corrosion on the terminals and for white or light green stuff growing between adjacent terminals. Individual wires in the harness should not be checked yet because that turns it into a mess. Instead, I use voltage measurements to see where it is being lost and where I have it, to figure out the area that has a break. If it comes to that, the circuit needs to powered up, and that normally only happens when the engine is running. To avoid the need to do that, there will be a relay that can be bypassed. Doing that is way easier than trying to describe how to do it, but I can do that too if necessary.

The only time we replace a harness is to replace just a section if it got smashed in a crash. To do that, we cut off a good section from a vehicle in a salvage yard, then splice it into the car's harness. Professionals never never ever use crimp-type butt connectors and especially not Scotch-Lok squeeze-together connectors. Those do not seal out moisture, and will cause a big pile of problems in the near future. My only acceptable repair is to splice and solder the wires, then seal them in heat-shrink tubing. There is even heat-shrink tubing available with hot-melt glue inside to really do a good job of sealing where water can get on them. Also, it is a bad idea to wrap a repaired harness, or a splice, with electrical tape. That will unravel into a gooey mess on a hot day.

Thursday, May 18th, 2017 AT 11:15 PM