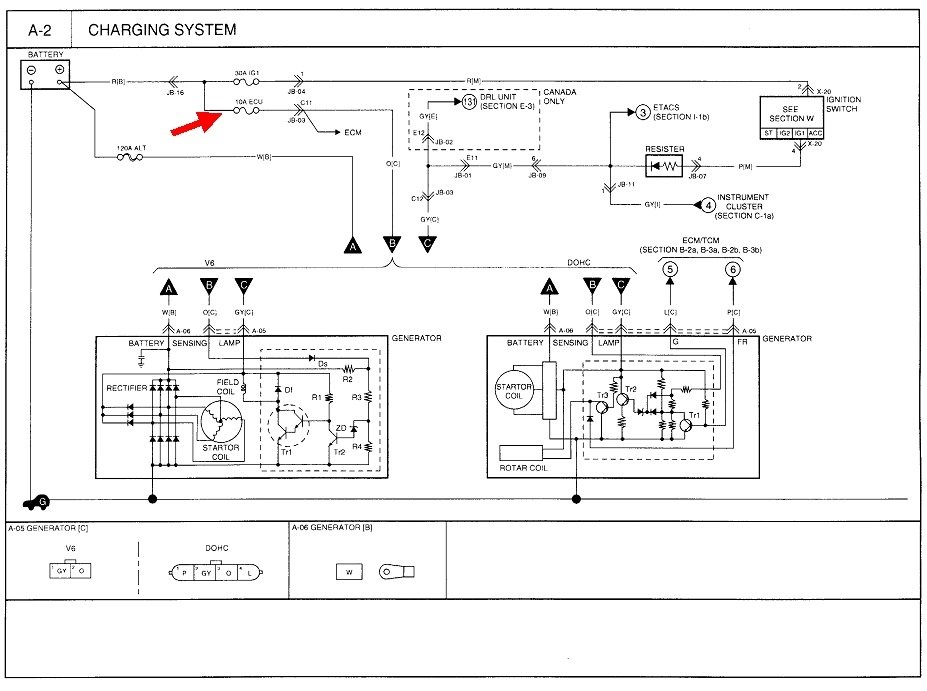

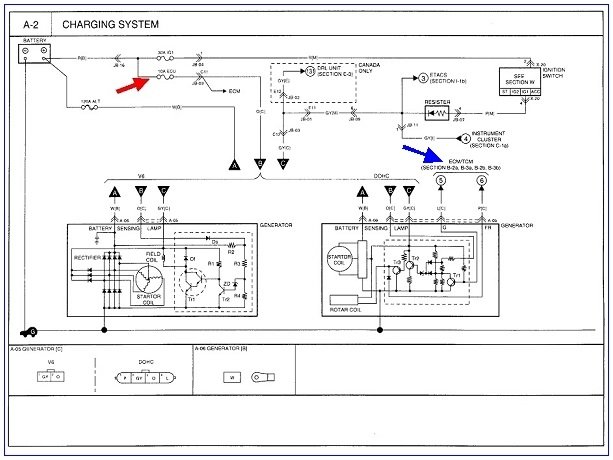

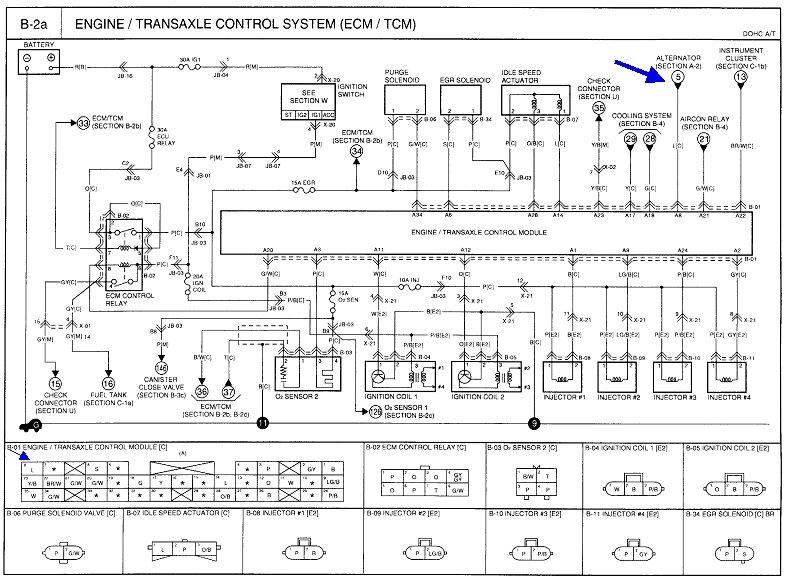

Technically, yes, but in every system I've ever looked at, there has always been a resistor across that dash light exactly for that purpose if the bulb burns out. This circuit looks similar to some others even though the diagram seems somewhat confusing. If you can't read this, I'll cut it in half, then enlarge it for you.

Check for full battery voltage on the large output wire when the engine is off. For this type of problem, a cheap test light, (one with an incandescent bulb inside), can be more accurate than a digital voltmeter.

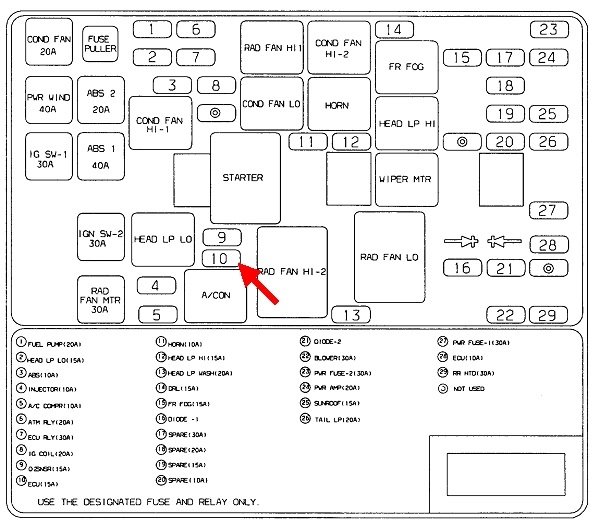

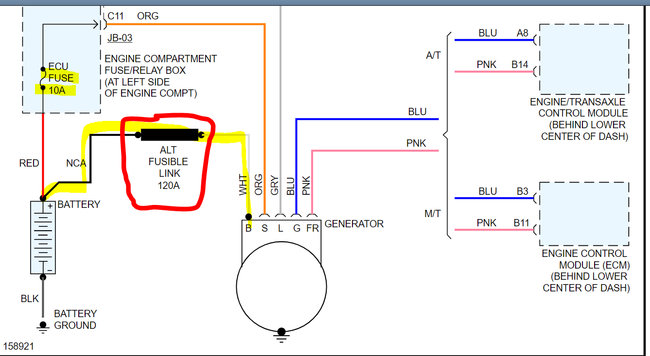

Next, there should be full battery voltage at all times on point "B", which looks to be an orange wire. If that is missing, suspect the 10-amp "ECU" fuse. That's the one with my nifty red arrow, but it feeds the Engine Computer too, so you should be diagnosing a crank / no-start issue if that fuse was blown. This is the fuse that is commonly blown and commonly overlooked on Ford products.

While it isn't obvious, it looks like the field winding gets energized on the gray wire, point "C", when the ignition switch is turned on. The resistor they show between the ignition switch and point "C" does not appear to be the one used when the dash light burns out. In fact, I'm not sure what it is for, but that is a good suspect if you're missing the 12 volts on that gray wire. This does not appear to be a "turn-on" circuit as they do it on Fords. We're lucky in that they show a representation of what is inside the voltage regulator.

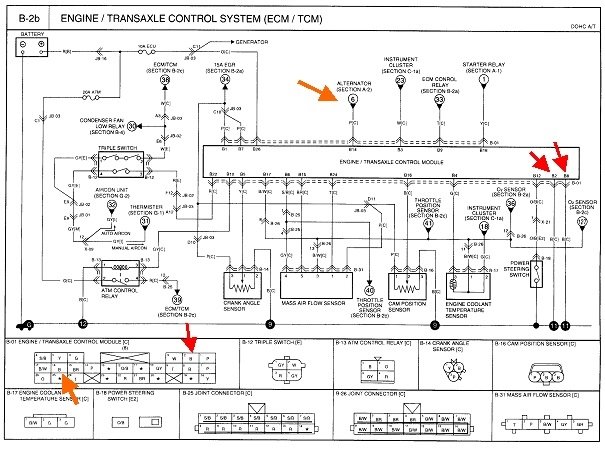

Let me start by describing how the Ford system works because that might shed light on this system in a minute. With Fords, their yellow wire, (the orange one on this Kia system), has 12 volts all the time, and that is the feed for the field winding. The other end of that winding gets grounded and controlled by the voltage regulator, and the regulator turns on to do its thing when it gets current flow on the green / red wire from the dash warning light. Since the light bulb drops most of the 12 volts, you're left with around 2.0 volts on that wire at the generator, (gray wire here). That 2.0 volts is enough to tell the regulator to turn on and start conducting some current through the field winding. Now you have a magnetic field and the stationary stator winding. All that's left is the most important thing, that is movement between them. Once the engine is running, the movement causes voltage to be induced in the stator, and that produces the output current. System voltage continues to be monitored on the yellow wire, then the regulator adjusts how much current flows through the field winding, to control output current and voltage.

Once the system is developing an output, a sample of that is tapped off and goes right back into the voltage regulator to tell it the system is working. (That's the short white / black wire on the Ford generator). In response, the regulator sends full charging voltage back out on the green / red dash light wire. With that full system voltage on one side of the warning bulb, and the same full system voltage on the other side of the bulb, from the ignition switch, the difference is 0 volts, so the bulb goes off.

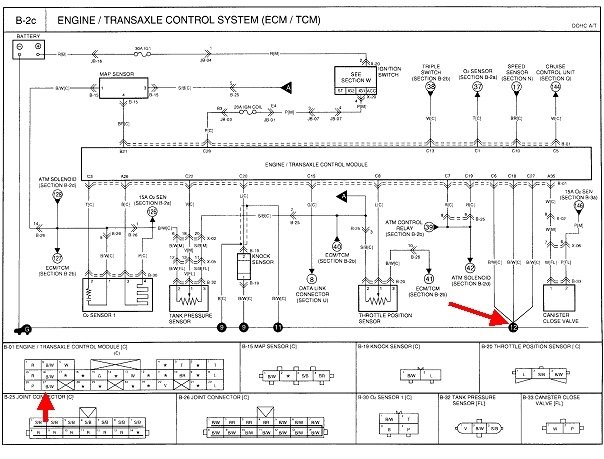

Here, in your Kia system, operation isn't so easy to follow. System voltage is still monitored on the orange wire, but that is not the current supply for the field winding, at least not as the representation is drawn. Since this is a constant feed to the internal circuitry, there has to be some other way to stop current flow when the engine is off, to prevent draining the battery overnight. It looks like that is all done with the gray wire from the ignition switch. That feeds the field coil directly, then current flow continues through a regulating transistor, then to ground. Of interest is right above the field coil, the circuit taps off to the right and feeds the rest of the circuitry. This is where it differs from the Ford system, and while it is a simpler design, it is not obvious what turns the dash light on and off.

If you look again at that resistor, the circuit goes to the instrument cluster at point "4". Stop there for a minute, and look at the three diodes on the left side of the left alternator diagram, right under the word, "rectifier". That is the same "diode trio" used for many years in GM generators, up to 1986. Once the system is up and running, a small sample of current goes through those three diodes and continues to supply the current for the field winding, and it goes back to the dash light to turn it off. It looks like that's what they're doing here too.

My suspicion is when you turn on the ignition switch, current flows through the "dropping" resistor, then what voltage remains is applied to the field winding. That may be only 2 volts, but that would be enough to get the process started. I also suspect there's 12 volts applied to the other side of the dash light, so with 12 volts on one side and 2 volts on the other, the light turns on.

Next, when the engine is running, the current developed through the diode trio brings the voltage feeding the field coil up to full charging voltage, and keeps going higher and higher until the regulator kicks in to limit any further voltage increase, and at the same time, that full voltage goes back to the dash light to turn it off.

So, ... Now that I've shared all that wondrous information, it looks like the gray wire is where we're going to find the problem. You may need to resort to using a digital voltmeter to see what you have when you back-probe that wire. Expect to see a low voltage there before you start the engine, and the dash light should be on. If those two things are missing, suspect a break in that wire, the resistor is burned open, or the connector terminal is spread and not making contact with its mating terminal at the generator.

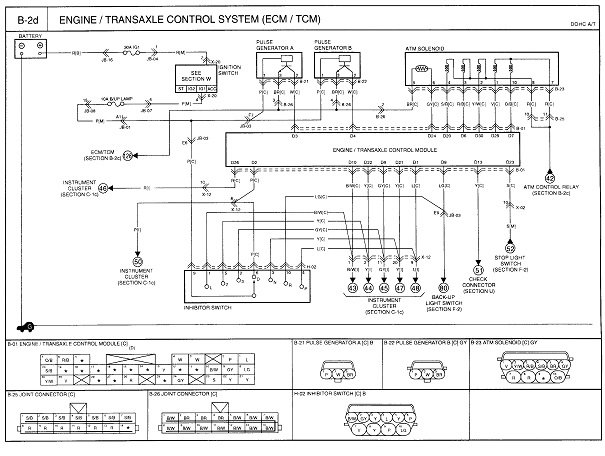

Even when that gray wire has a problem, that circuit is only there to insure the system starts up. There is often enough residual magnetism in the field winding, (rotor), to get the system started, then it will "self-excite" through the diode trio and get up to full output instantly. Since the third important ingredient in generating a voltage this way is the movement between the stator and the magnetic field, you often have to raise engine speed to get the system to self-start. Once it is started, as with the Ford systems, you can take the gray wire away and the generator will keep right on humming along as long as the rotor keeps on spinning. Once the engine is stopped, you'll have to go through that again and hope it self-starts again. This used to be common on hot rods that used a GM generator with only a single output wire going back to the battery. There were no other wires connected to it. They relied on that residual magnetism to eventually get it going once the engine reached a high enough speed.

Images (Click to make bigger)

Friday, January 10th, 2020 AT 6:39 PM