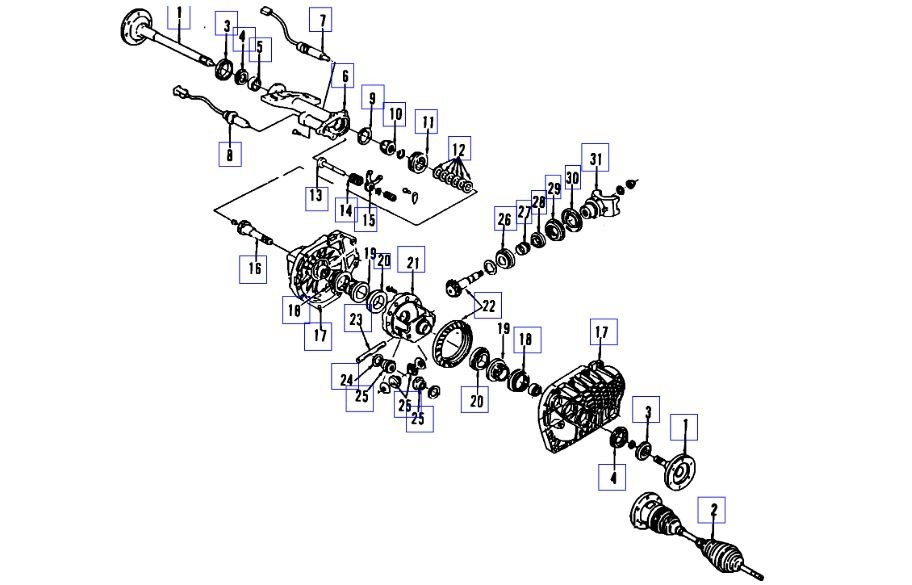

Procedure for removal:

1. Remove differential side bearings using a suitable puller or press.

2. Remove ring gear attaching bolts and the ring gear.

3. Scribe an alignment mark on both case halves, then remove bolts holding case halves together.

4. Tap top half of case loose from bottom, then remove top half and all internal components.

5. Position new washers on side gears, using a small amount of lubricant on side gear hubs.

6. Install pinion gears and new washers onto cross shaft.

7. Assemble top half of case to bottom half, using alignment marks made during disassembly. Tighten bolts alternately and evenly.

8. Install ring gear and torque bolts alternately in stages to 110 ft. Lbs on 10-1/2 inch axles, 220 ft. Lbs. On 11 inch.

9. Position side bearings onto case and seat bearings using a suitable driver. When installing second bearing, support case with suitable pilot to prevent damaging case of opposite bearing.

10. Determine side bearing shim requirements as follows:

a. Place bearing cups over side bearings and install differential case into carrier, with pinion removed from carrier.

B. Position original shim in ring gear side, then install bearing caps and tighten just enough to retain in place.

C. Install a dial indicator on carrier with indicator button contacting back surface of ring gear.

D. Position two screwdrivers between bearing shim and carrier on ring gear side of case. Apply force to screwdrivers to move differential case as far as possible away from dial indicator. With force still applied, set dial indicator to 0.

E. Reposition screwdrivers on opposite side of differential case and force differential case back toward dial indicator. Repeat sequence several times until same reading is obtained.

F. Add thickness of shim to dial indicator reading and record the result.

Friday, May 14th, 2021 AT 11:33 AM