Hi,

Yes, fuel delivery and pressure is one of the possible causes of P0422 and apart from vacumn leakages, exhaust leakages would cause it too. however it shold be noted that the cleaning might not fully clear clogged injectors.

Was exhaust checked for leakages between exhaust manifold and catalytic converter?

Here are some testing procedures that you can carry out.

1. Perform fuel pressure test, maximum fuel pressure test and fuel pressure hold test. If fuel pressure tests are within specifications, go to next step. If any fuel pressure test is not within specification, repair fuel system as necessary.

2. Perform fuel injector inspection and volume test. If all fuel injectors are operating properly, go to next step. If any fuel injector is not operating properly, repair appropriate fuel injector.

3. Check vacuum hoses for leaks. Check purge solenoid valve for proper installation and operation. If problem exists, repair as necessary. If problem does not exist, go to next step.

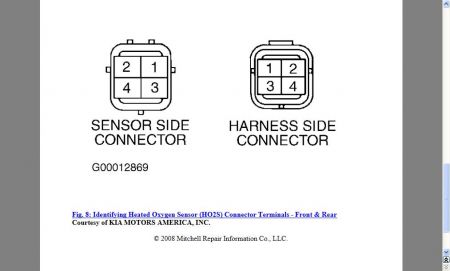

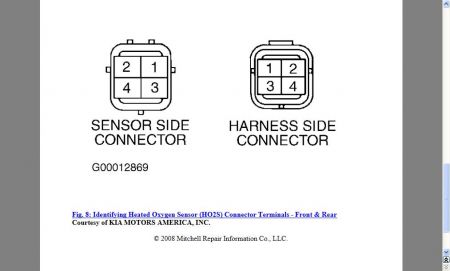

4. Backprobe and monitor voltage between front HO2S connector terminal No. 4 (Green/Brown wire) and ground. See Fig. 8 . Start engine and allow it to warm-up to normal operating temperature. With engine idling, spray short spurts of aerosol carburetor cleaner into following areas while observing voltage changes:

Throttle body gasket.

Gasket between intake manifold and cylinder head.

Gasket between intake manifold and surge tank.

Seals between intake manifold and fuel injectors.

Seal between surge tank and PCV pipe.

A long rise in voltage that corresponds to approximate timing and duration of spray of carburetor cleaner indicates air leak in area sprayed. If leak is indicated, repair leak as necessary. If no leak is indicated, go to next step.

5. With engine idling, have helper hold wadded rag against tailpipe. Listen for exhaust leaks between main catalytic converter and cylinder head. If exhaust leak is detected, repair as necessary.

Wednesday, February 4th, 2009 AT 2:43 PM