Which harness are you referring to? The '86 5th Ave only came with a 318 c.I. And a carburetor. It was my dream car for many years. If you dumped a 360 c.I. Into it that also used a distributor, that should be a simple replacement. I'm going to check further, but unless the distributor drive gears are different, your '86 distributor should drop right in. The issue is going to be fuel. If you can bolt on the carburetor, you'll be all set. If you're going to try to run the fuel injection system that came with the '97, you'll need the crankshaft position sensor behind the right cylinder head. It's actually in the front edge of the transmission bell housing. Those get damaged if they aren't removed while separating the engine and transmission from each other.

You'll need the flex plate with the ring next to the starter's ring gear. That has notches, or holes, in it that are read by the crankshaft position sensor. Those flex plates went through multiple changes or variations over the years, so you want to keep the flex plate with the Engine Computer. That insures the computer sees the correct number of groups of signal pulses per revolution.

That computer is also gong to need to see all the sensor readings from the engine. Where you may run into trouble is with all the other missing stuff. The fuel injection engines need around 45 - 50 psi fuel pressure, not the 3 - 5 psi from the mechanical fuel pump run off the camshaft. The Engine Computer talks back and forth with the instrument cluster, the Body Computer, and the Transmission Computer. You won't have those. Your original dash gauges can be easily made to work, (with my help, of course), but my fear is with so much missing, the Engine Computer is going to see that, set multiple diagnostic fault codes, and turn on the Check Engine light which you also don't have. That light is not turned on by 12 volts simply coming out one wire from the Engine Computer. Rather, the computer sends a long list of digital information to all the other computers, then the instrument cluster reads all of that, picks off just the data it needs, then runs the gauges and warning lights through the cluster, which is another computer module. Without the Check Engine light, you'll never know when the computer has detected a problem. Two issues with that. First, once the Check Engine light is on, it might be due to a relatively minor problem, but if a second, more serious problem develops, you'll never know because the warning light is already on and being ignored. That new problem, if ignored, could turn costly.

Second, once the Check Engine light turns on, it's due to one or more diagnostic fault codes. The computer has many strategies for determining when a defect exists. One of those strategies is it compares many sensor readings and engine operating parameters to each other. For example, it knows when the engine has been off for at least six hours, both the intake air temperature and the coolant temperature sensors had better be reading the same temperature. To set any fault code, there's always a long list of conditions that must be met. One of those conditions is certain other codes can't already be set. In this example, if a code is set for the coolant temperature sensor, the computer knows it can't trust it for comparing to other sensor readings. In this case some of the self tests for the intake air temperature senor will be suspended. It could also develop a problem resulting in an elusive running problem, but you'd have no fault code directing you to the correct circuit or system. You have to fix the coolant temperature problem first, then the self tests for the intake air temp sensor will resume. That's when new defects related to the IAT will finally get detected.

'96 and newer models also switched to using the "on-board diagnostics, version 2", (OBD2) emissions system. Those had two primary systems added over '95 and older fuel-injected engines. One was the addition of an oxygen sensor after the catalytic converters. Those were simply to monitor the efficiency of the converters. They had no effect on engine performance. Your '97 computer is going to want to see those signals and they must be drastically different from the O2 sensor readings ahead of the converter, where it is on your '86 model. I'd assume the O2 sensor is different on your '86 too and won't be acceptable to the computer.

The second big difference has to do with your charcoal canister and other emissions systems. Your canister just sits there as does its job with very little for electric controls. The '97 computer runs solenoid-controlled valves to purge the stored gasses out of the canister to be burned. The computer will see any missing solenoid circuits. It also expects to see the front oxygen sensor readings go rich for a while when it commands the purge solenoid to open. That's part of what it looks for when it sets the fault code, "insufficient purge flow".

Who hasn't heard about the Check Engine light being on due to a loose gas cap? Part of the OBD2 system involves developing a pressure or a vacuum in the fuel tank, then the computer watches how quickly those change to determine if there's a leak. Chrysler typically uses a motor-driven pump to put the fuel supply system into two pounds of pressure. That pump is commanded on by the Engine Computer. I don't see a practical way to add that to your car unless, at a minimum, you install the truck's gas tank and fuel pump. As the current owner of a 2014 Ram, two '80 Volares, and the past owner of two LeBarons, (twins to your car), I can guarantee those gas tanks will never interchange.

I don't see a practical or cost-effective way to do this conversion. What I would suggest is searching the internet for a company that offers a retrofit kit. I've heard stories to this effect, but I've never looked into them. Be aware too the 318 engine block was used for a real long time and parts interchanged from the late '60s through the '89 models. Chrysler was famous for great parts interchangeability. That's one of the many reasons I'm a fan.

The '97 engine block is going to be different in many ways. I'd like you to let me know if the exhaust manifolds bolted up directly, and I think the transmission bell housing and bolt pattern are the same. My understanding is the newer models, often referred to as "Magnum" engines, use a very different cylinder head design. You'll want to research this further, but as I recall, the newer cylinder heads will not bolt onto an older engine block, (something about push rod placement), and the newer intake manifold only mates to the newer cylinder heads. That means even as a complete assembly, you can't transplant your older heads and intake with carburetor onto the newer block.

If you can find an aftermarket supplier that offers an Engine Computer and wiring harness that will run the engine directly when all the other computers are missing, that is the way to go. You might even find such a kit at the Chrysler Dealer's parts department. They used to have a "Direct Connection" catalog with all kinds of racing and high performance parts and kits. Much of that has gone by the wayside due to strict emissions laws, but there's still a lot of fun stuff available listed as for "off-road use".

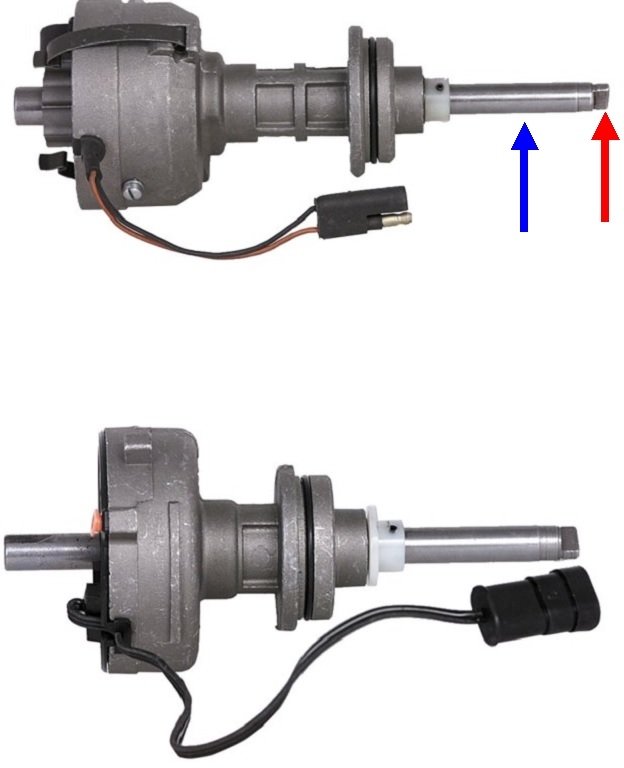

Here's photos of the two distributors. The top one is for your '86. It has no vacuum advance unit hanging on the side, so it will also not have mechanical advance built in. Both are handled by your Engine Computer hanging off the air filter housing. The bottom one is for your '97 360. Note both have the same screwdriver blade end, (red arrow), that is driven by the intermediate gear / camshaft, that also drives the oil pump. The shaft, (blue arrow), also appears to be the same. That makes it a drop-in interchange mechanically. The issue will be with the pick-up assembly inside the distributor. The older one uses a two-wire magnetic pick-up. A few models had distributors with two of those across from each other. I can help with that if necessary, but those are very rare. The air gap for those pick-ups is pretty critical.

The newer distributor uses a "Hall Effect" pick-up assembly with three wires. Those are a 5-volt feed, a ground, and the signal wire. The computer only cares about the signal wire, but that is in addition to the crankshaft position sensor. The computer also supplies the 5 volts to run those two sensors, along with many of the other sensors.

Image (Click to make bigger)

Thursday, April 7th, 2022 AT 8:00 PM