ROCKER ARM SHAFT ASSEMBLY Removal 1. Disconnect spark plug wires, PCV and fuel evaporation hoses. Remove valve cover. Remove bolts and retainers attaching shaft assembly to cylinder head. 2. Remove rocker arms and shaft assembly. Label push rods to ensure installation in original location, then remove. Refer to Fig. 3 and Fig. 4 if rocker arms are being removed from shaft. Fig. 3: Identifying Rocker Arms Note Difference In Rocker Arms. Installation 1. Install rocker arm and shaft assembly with notch on end of rocker arm shaft pointing to centerline of engine and toward front of engine on left bank, to rear of engine on right bank. 2. Ensure that long, stamped steel retainers are installed in number two and four positions. Tighten bolts to 200 INCH Lbs. (23 N.m). Reverse removal procedure to complete installation. Fig. 4: Location Of Rocker Arms Install Long Retainers In Number Two And Four Positions. Page 1 of 1 5.2L V8 - VIN [T] & 5.9L V8 - VINS [I,V,W] -1985 Dodge Pickup D100

Lifters are hydraulic, if noisy you may need to remove and clean or replace them, no adjustment.

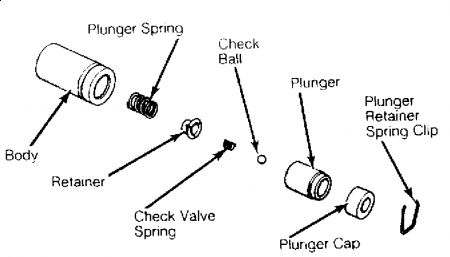

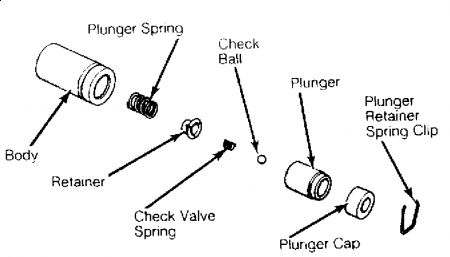

HYDRAULIC VALVE LIFTERS 1. Prior to testing, disassemble lifter. Clean lifter inside and out to remove varnish and carbon deposits. 2. To test, remove cap from plunger and plunger from lifter body. See Fig. 7 . Fill lifter body with clean kerosene. Unseat check valve to permit complete installation of plunger. Install cap. Fig. 7: Hydraulic Lifter Assembly Parts Are Not Interchangeable Between Lifters. 3. Place lifter upright in Lifter Tester (C-4343) and check leakdown by compressing tool. If lifter collapses immediately, disassemble, clean and retest. If rapid leakdown still occurs, replace lifter. 4. If lifter or lifter bore in cylinder block is scuffed, scored, or shows signs of sticking, ream bore to next oversize and replace with oversize lifter. Removal 1. Drain cooling system (partial) and remove air cleaner. Remove valve cover and rocker assembly and push rods and identify push rods to insure installation in original location. Remove upper radiator hose, heater hose and bypass hose from intake manifold. 2. Remove distributor and intake manifold assembly. Remove lifters. If all lifters are to be removed, identify lifters to insure installation in original location. Installation 1. Lubricate lifters. Install lifters and push rods in their original positions. Install rocker arm and shaft assembly. Clean all mating surfaces and install intake manifold with new gaskets. 2. Connect all hoses and refill cooling system. Install valve cover. Install distributor, start engine and retest timing. CAUTION: The plunger and lifter bodies are not interchangeable. The plunger and valve must always be fitted to original body. It is advisable to work on one lifter at a time to avoid mixing of parts. Mixed parts are not compatible. DO NOT disassemble a lifter on a dirty work bench. CAUTION: To prevent damage to valve mechanism, engine must not be run above fast idle until all hydraulic lifters have been filled with oil and have become quiet. Page 1 of 1 5.2L V8 - VIN [T] & 5.9L V8 - VINS [I,V,W] -1985 Dodge Pickup D100

Saturday, March 7th, 2009 AT 7:38 AM