Sunday, November 4th, 2018 AT 8:12 AM

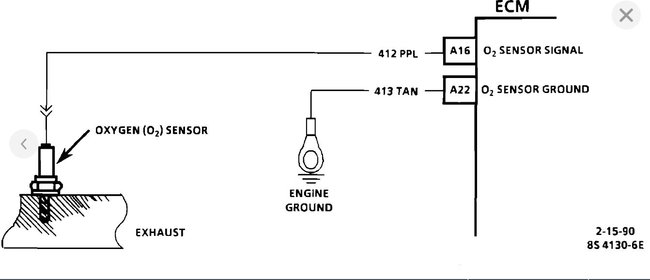

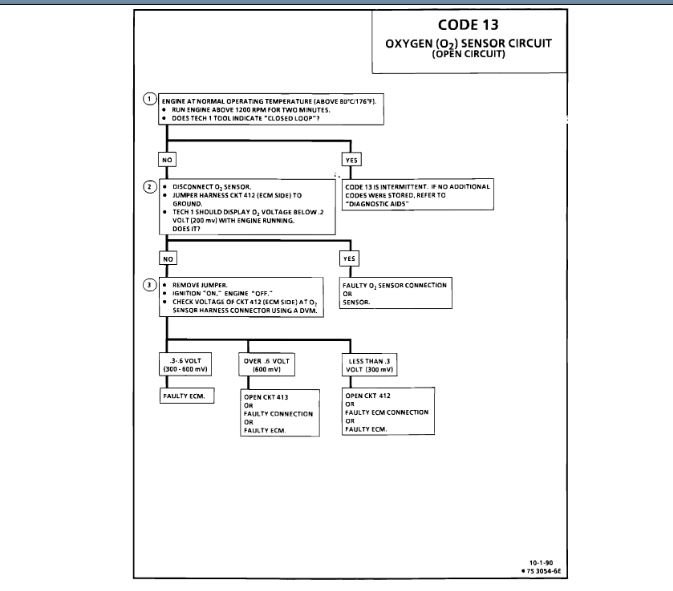

It started out with the engine staling when I came to a stop or as I was turning a corner always at low RPM. This has been going on for around four months. I checked the fuel pressure, signal to the TPS. One thing that was always a constant was the code 13, O2 sensor. I replaced these sensors MAP, TPS, Air intake temperature, IAC, crankshaft position, O2 was done twice. Also the ECM I replaced twice in the last three months. The second I installed four days ago. A shop owner scanned my car and nothing stood out but he removed the ECM from its location laid it on his hand as the engine was running and gave it a slap. The engine shut off. There is an inherent problem with these ECM from this time period as the conformal coating applied by GM swelled, causing movement of the electronic components and cracking of critical solder joints. This information is found at Rockauto catalog under the ECM-CARDONE supporting information. He told me that he learned that at the dealership. I replaced the ECM and the car was fine for about two weeks and then the stalling returned. I then replaced the TPS and it ran fine for another two weeks and then the nightmare returned. I for the first time did the idle relearn procedure two days ago and that made a big difference but it stalled out only once so far but when I drove on the beltway at about 65 MPH the service engine light returned and there it was code 13 the O2 circuit all by its self. I buy my parts from Rockauto and use AC Delco when available as is the O2 and the others. Code 13 only appears when I drive at highway speeds such as 65 then the service engine light comes on but not until I am driving at high speeds. I could drive all day long at 40 and bellow and the code 13 will never appear or any other. I Replaced the battery nine days ago. From the information that I have gathered it seems to be a problem with the O2 circuit such as the ground. Any and all input will be appreciated. Thanks