How was that off-car testing done? There were three alternators available on that model; the 160-amp, 180-amp, and the 220-amp that you listed, but you can only have one of them. Off-engine testing is not effective as for a tiny 65-amp unit it can take over five horsepower to run it, and no bench testers have drive motors that big. Most have a one horsepower motor or less. Testing should also include the charging voltage, and a measurement for "ripple" voltage. Most on-car testers just show ripple voltage as "low" or "high" with a series of flashing LED lights. A few models can make printouts of the results. Those often show ripple voltage as an actual voltage value.

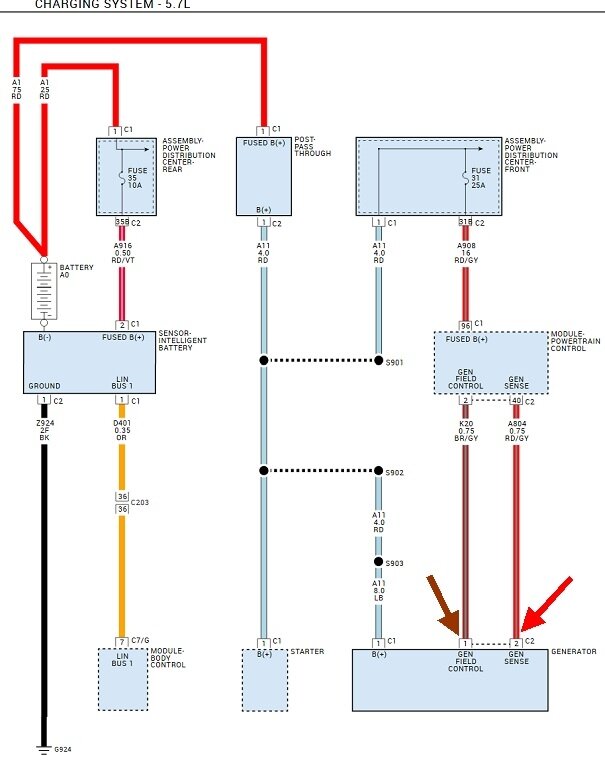

If you found 11.7 volts on the alternator's output stud with the engine not running, we know that circuit is okay. The secret to starting the diagnosis is in checking the voltages on the two smaller wires on the back of the alternator. On all older Chrysler models that had to be done with the engine running because the voltage to power the alternator's field winding came through the automatic shutdown, (ASD) relay which got turned on during engine rotation, (cranking or running). The way this diagram is drawn, it looks like that voltage is there all the time. Regardless, the engine has to be running for these voltages to be valid.

Start on the brown / gray wire. The terminology can be confusing, but normally the "generator field control" has full system voltage with the engine running, and the red / gray wire, "generator sense", will have less, but not 0.0 volts. Typically on that red / gray wire you'll find between 4 and 11 volts. The lower that voltage, the bigger the difference is in the two, and the bigger electromagnetic field is developed, meaning more output current is developed.

Let me know what you find with those two voltages.

Thursday, October 16th, 2025 AT 11:51 AM