I had wheel speed sensor and ABS module codes. I replaced both, but the problem still persisted when I start driving at a low speed and have to stop before I get up to road speeds.

Once I'm up to normal driving speeds, I don't have a problem stopping.

I had the truck 'scoped' at a shop. They told me there were no codes, but the reading showed my speed always stopped at 3 MPH and was never recorded as reaching 0 MPH indicating a full stop.

At first, I thought this was due to my oversized tires which caused my speedometer to read slower than my actual. I had a shop put on a set of tires 3 sizes lower than my actual tires, but the problem persisted, so I returned to the larger tires.

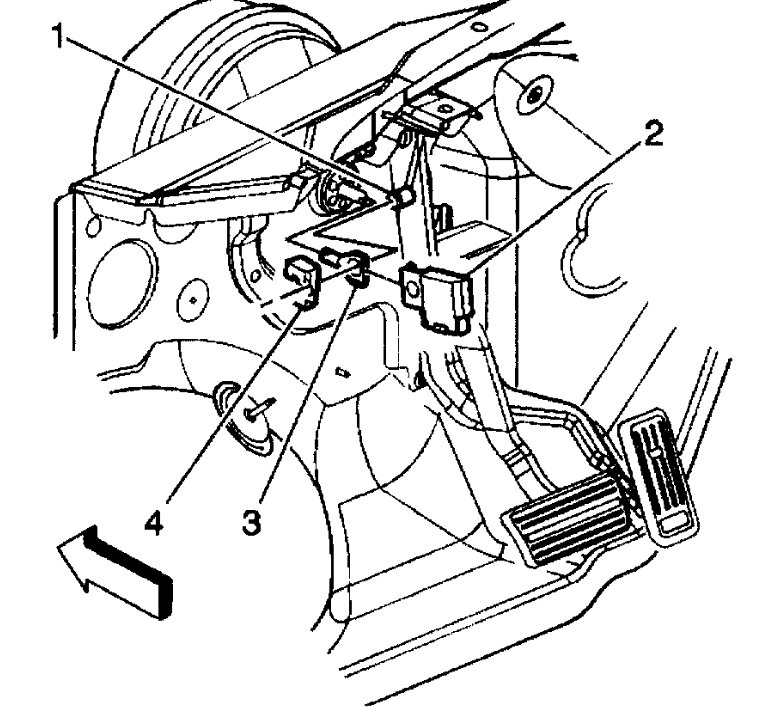

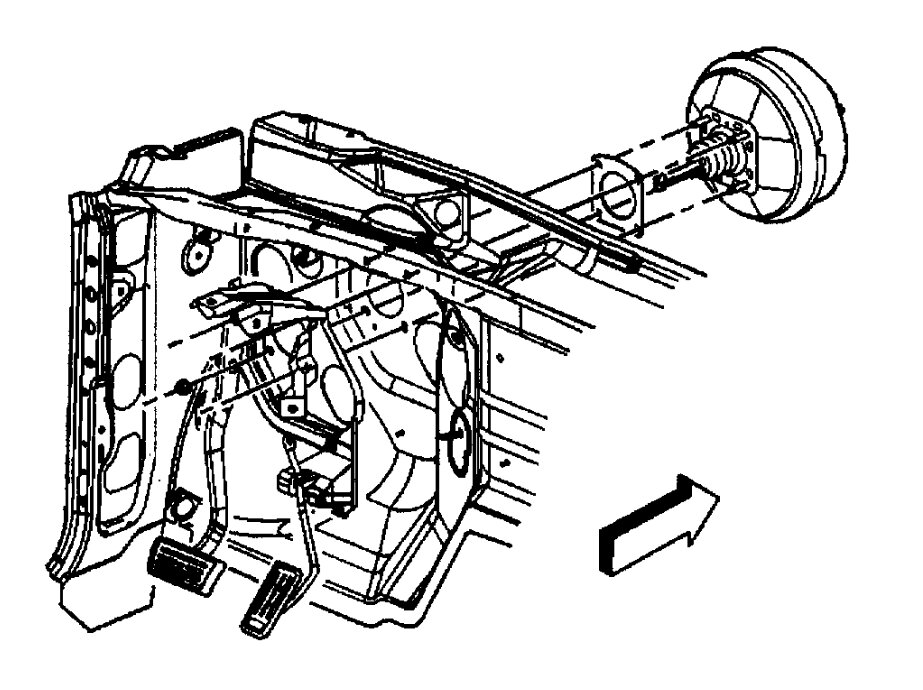

One day last week, it happened again. I was so close to the car in front I was scared and really pushed down on the pedal trying to stop the truck. When I did, I felt a release of pressure, and the brakes worked, and I stopped!

So now, I have two theories about this:

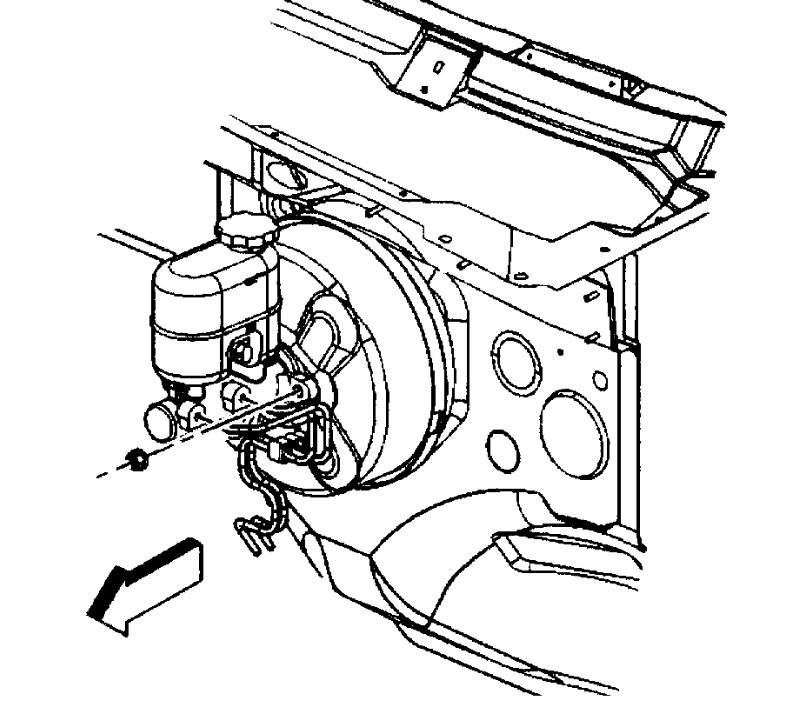

1. It's a hydraulic issue related to my Booster or

2. If the sensor believes I'm always at 3mph, then when I start a '0' and then have to stop before I make driving speed, the ABS won't work to stop my brakes. Or both theories are wrong, and it's something else. I'm open to any and all suggestions. Help!

Friday, April 18th, 2025 AT 5:00 PM