If it was the fact three fuel filter as you stated with 193,000 miles I'm afraid that the fuel pump may have suffered some damage.

Application Pressure psi (kg/cm2 ) Volume In 30 Sec. Pts. (L)

850 Non-Turbo 43.5 (3.06) 1.1 (.52)

(1) At 12 volts, 68°F (20°C), with engine off and fuel pump relay by-passed.

First thing I would do is check the fuel pressure it should be up 43.5 psi

FUEL SYSTEM

NOTE: For wire color and terminal identification, see appropriate WIRING DIAGRAM in WIRING DIAGRAMS article.

WARNING: Always relieve fuel pressure before disconnecting any fuel injection-related component. DO NOT allow fuel to contact engine or electrical components.

FUEL PRESSURE

Before disconnecting, cover fuel line connector using shop towel to absorb any fuel spray. Connect Fuel Pressure Gauge (5011 ) between fuel line and fuel rail. Seal free end of hose using Plug (5266 ) or use Fuel Drainage Unit (981 2270, 2273 and 2282 ).

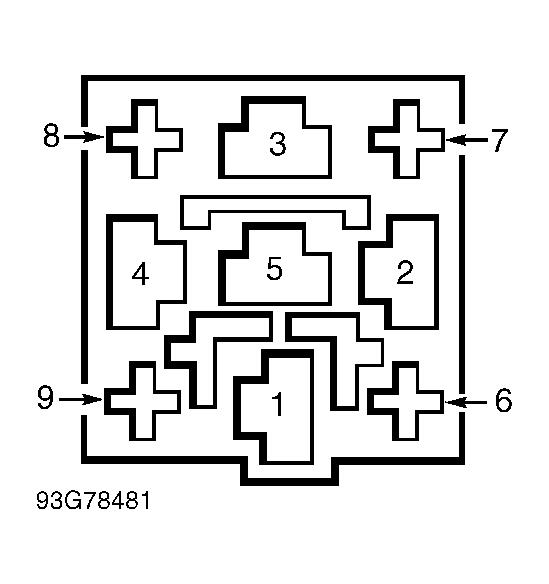

Remove fuel pump relay. Connect a jumper wire between relay terminals No. 1 and 3. See Fig 1. Turn ignition on. Fuel pump should start. Fuel filler cover can be removed to determine whether main pump is operating. Fuel pressure should be about 43.5 psi (3.0 kg/cm2 ). If pressure is not to specification, replace pressure sensor.

To check fuel system residual pressure, turn ignition off. Disconnect jumper wire between relay terminals. Reinstall fuel pump relay. System pressure should not drop below 29 psi (2.0 kg/cm2 ) in less than 20 minutes. If pressure is not to specification, check injectors, connections, and fuel pump non-return valve or lines. Repair as necessary.

Fig 1: Identifying Fuel Pump Relay Terminals

FUEL PUMP

Turn ignition off. Remove fuse No. 2. Connect ammeter between fuse No. 2 terminals. Turn ignition on. Using scan tool, activate fuel pump. If amperage is 4-5 amps, fuel pump is okay. If amperage is not 4-5 amps, go to next step.

Turn ignition off. Leave ammeter connected to fuse No. 2 terminals. Remove fuse/relay unit cover. Remove fuel pump relay at position No. 103. Turn ignition on. Connect jumper wire between relay connector terminals No. 1 and 3. See Fig 1. If amperage is 4-5 amps, go to step 6). If amperage is not 4-5 amps, go to next step.

Reinstall fuse No. 2. Turn ignition on. Connect voltmeter between fuel pump relay terminals No. 1 and ground. See Fig 1. Turn ignition on. If voltmeter reads battery voltage, go to next step. If voltmeter does not read battery voltage, check fuses and wiring.

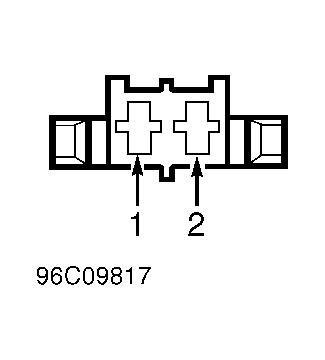

Turn ignition off. Disconnect 2-pin fuel pump connector in trunk. Connect ohmmeter between relay side of fuel pump connector terminal No. 2 and ground. See Fig 2. If about zero ohms are present, go to next step. If about zero ohms are not present, check connector terminals for poor terminal contact.

Connect ohmmeter between fuel pump side of fuel pump connector terminals No. 1 and 2. See Fig 2. If about 0.5-2 ohms are present, check wiring between fuel pump relay terminals No. 1 and 3 for an open circuit.

Turn ignition off. Ensure fuel pump relay is disconnected. Connect ohmmeter between relay base terminal No. 2 and ground. If about zero ohms are present, go to next step. If about zero ohms are not present, check for terminal contact in relay ground circuit. If relay ground circuit is okay, check wiring between fuel pump relay terminal No. 2 and ground.

Turn ignition on. Ensure fuel pump relay is disconnected. Connect voltmeter between relay base terminal No. 4 and ground. If about 4-5 volts are present, go to next step. If greater than about 4-5 volts are present, check wiring between relay terminal No. 4 and ECM terminal B27 for a short circuit to ground. If less than about 4-5 volts are present, disconnect ECM. Connect ohmmeter between relay base terminal No. 4 and ground. If infinite resistance is present, check for open circuit in wiring between fuel pump relay terminal No. 4 and ECM connector terminal B27. If infinite resistance is not present, check for short circuit in wiring between relay base terminal No. 4 and ECM connector terminal B27.

Turn ignition off. Reinstall fuel pump relay. Reconnect ECM and fuel pump. Attempt to start engine. If engine does not start, replace fuel pump relay. If engine does start, problem was poor contact in ECM, fuel pump, or fuel pump relay connection.

Fig 2: Identifying Fuel Pump Connector Terminals (850)

Images (Click to make bigger)

Friday, February 13th, 2015 AT 9:12 AM