Symptoms: The van has been experiencing a lack of power and a reduction in MPG. Down to 18 – 19 mpg from mid-20’s. The oil pressure was in the low acceptable range. The serpentine belt began to whine so I replaced it. After the whine was gone you could hear a “worble” sound.

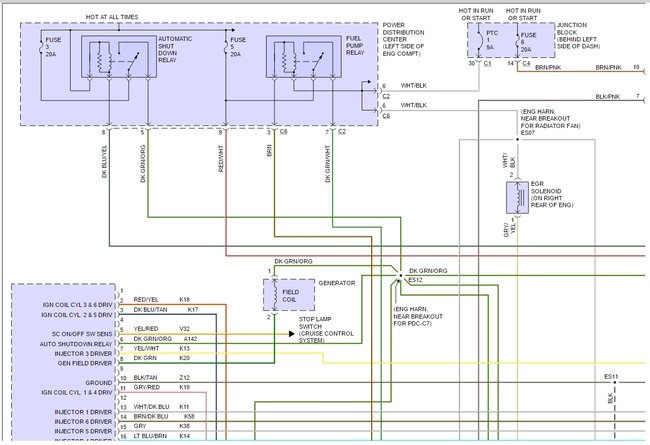

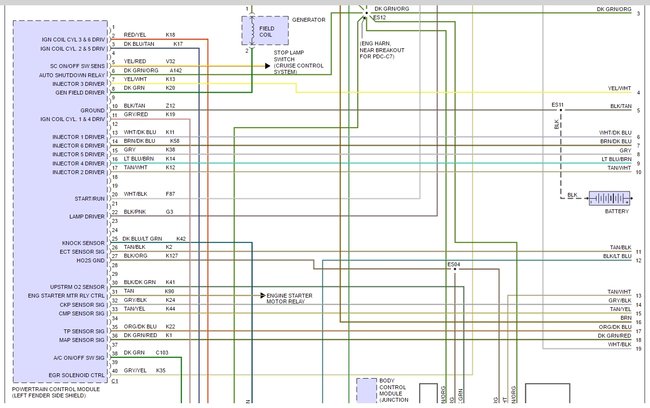

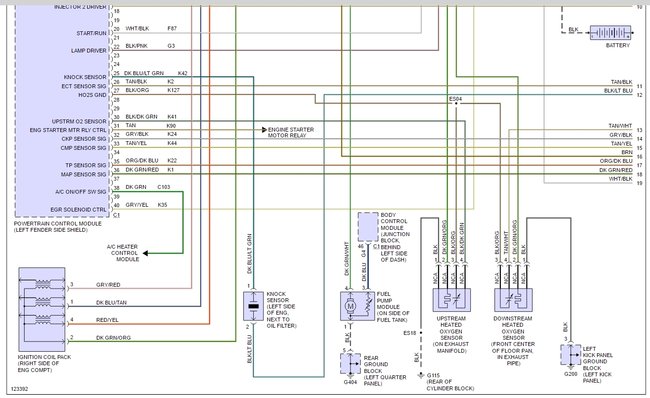

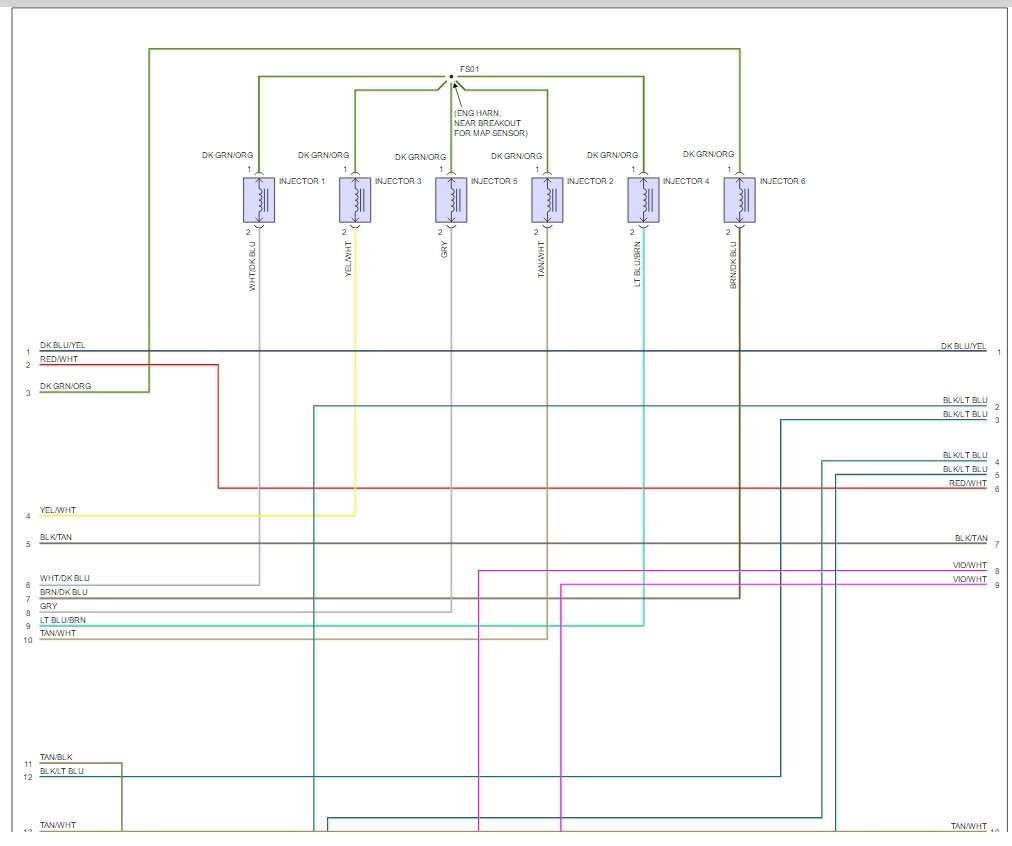

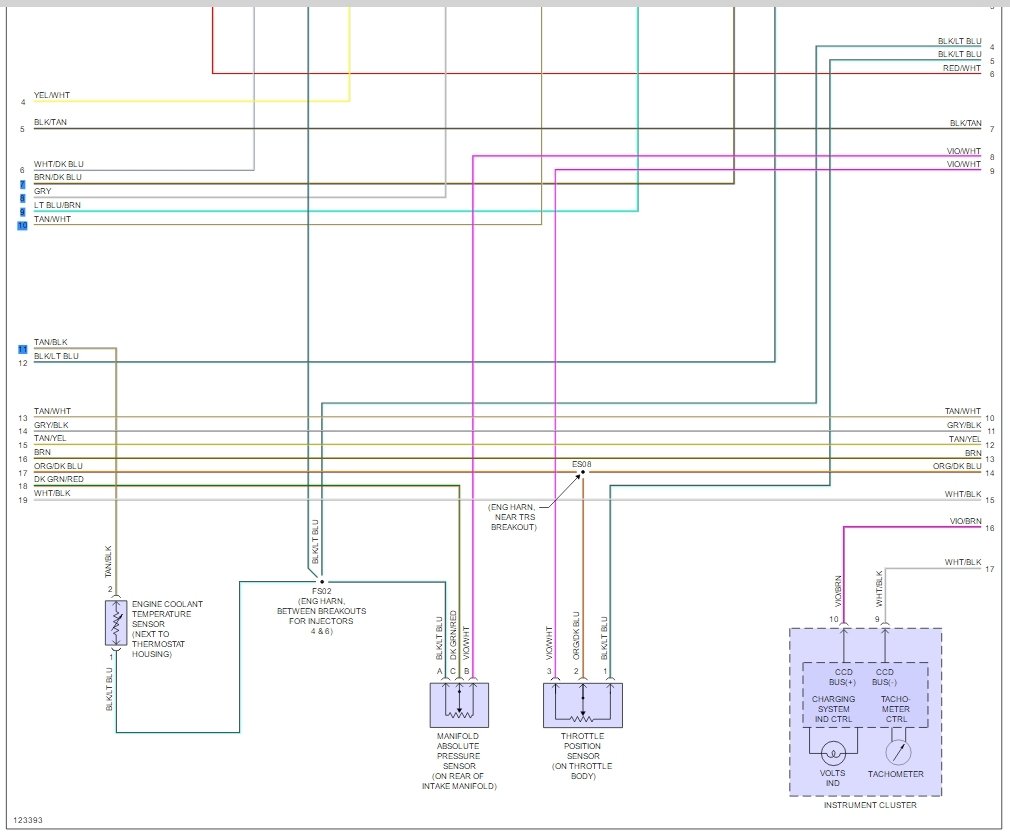

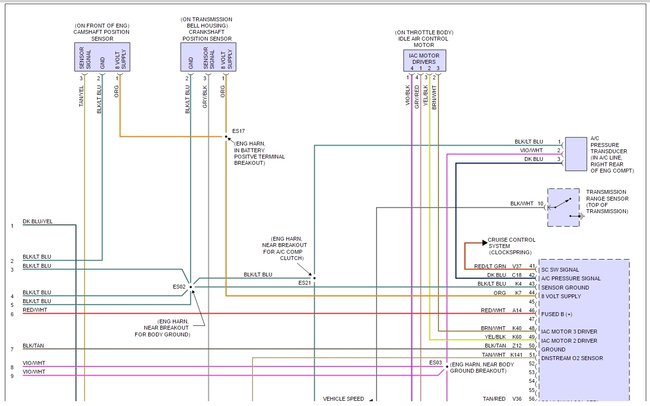

History: I took the belt back off and started the van in effort to discover if the “worble” was coming from any of the accessory equipment. The “worble” sound was still present which to me indicated a possible timing chain or oil pump issue. Upon investigation I found the timing chain had approx. 1.25’ total play from side to side on the rear portion of the chain. The oil pump was also out of tolerance. I replaced the timing chain complete with cam and crank sprockets and the oil pump. I made sure to line up the TDC arrows on both cam and crank sprockets as well as installing the chain so the colored links are in line with the dots at three o’clock on each sprocket. Since I was doing this work I also replaced the cam shaft position sensor, crank shaft sensor, water pump, tensioner pulley and idle pulley.

Now the van will not start

What I have investigated:

Battery is fully charged and at 12.4 volts.

Battery terminals are tight, clean and corrosion free.

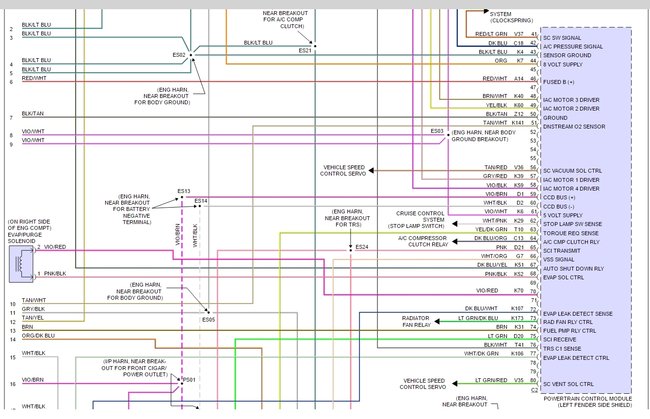

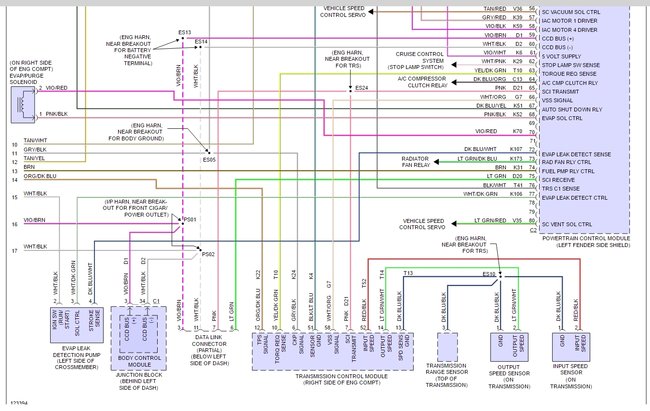

Checked the wiring harness as best I could for chaffing and/or breaks.

Checked all electrical connections and grounds

The fuel injectors are grounded.

The ASD relay is good.

Fuel pump is working and fuel rail is pressurized.

All fuses are okay.

The cam shaft position sensor is good. It is getting power and signals five volts

The crank shaft sensor is new

The coil pack test out at 12,500 ohms across the contacts on the secondary side and.9 to 1 ohm on the primary side.

Cylinder compression for cylinders 2, 4, and 6 is 210, 215, and 210 psi.

When testing the cam and crank sensor 5v signal I tested all the way back to the PCM.

I tested for spark at the coil pack and all 6 contacts sparked 2x then shut off.

Question:

The coil pack resistance is out of tolerance on the primary side by approximately 0.3 ohms. Is this enough to cause the PCM to trigger the ASD? If so why is it doing it now when the van started right up and ran before doing this work?

SPONSORED LINKS

Tuesday, October 18th, 2016 AT 1:35 PM