If you turned the engine over before installing the oil pump gear then CMP sensor relationship must be reestablished. Here is the procedure. You will need a scan tool also to see if it is sync or not.

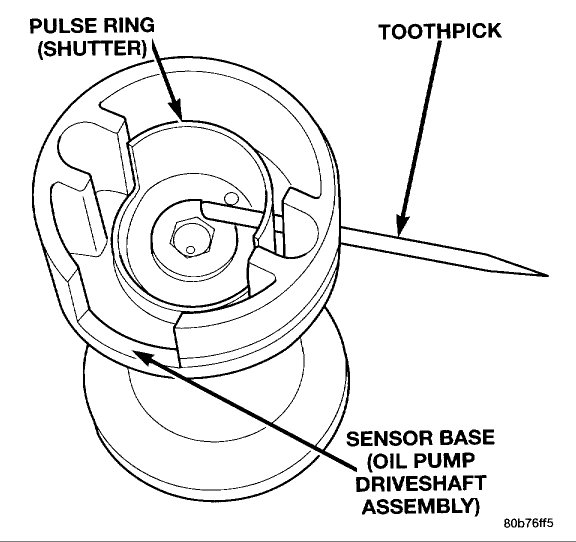

Temporarily install a toothpick or similar tool through access hole at side of oil pump drive housing. Align toothpick into mating hole on pulse ring.

Install oil pump drive into engine while aligning into slot on oil pump. Rotate oil pump drive back to its original position and install hold-down clamp and bolt. Finger tighten bolt. Do not do a final tightening of bolt at this time.

If engine crankshaft or camshaft has been rotated, such as during engine tear-down, CMP sensor relationship must be reestablished.

Remove ignition coil rail assembly. Refer to Ignition Coil Removal/installation.

Remove cylinder number one spark plug.

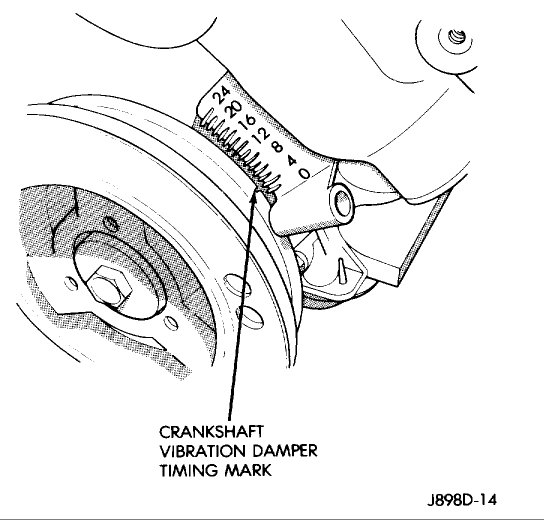

Hold a finger over the open spark plug hole. Rotate engine at vibration dampener bolt until compression (pressure) is felt.

Slowly continue to rotate engine. Do this until timing index mark on vibration damper pulley aligns with top dead center (TDC) mark (0 degree ) on timing degree scale. Always rotate engine in direction of normal rotation. Do not rotate engine backward to align timing marks

Install oil pump drive into engine while aligning into slot on oil pump. If pump drive will not drop down flush to engine block, the oil pump slot is not aligned. Remove oil pump drive and align slot in oil pump to shaft at bottom of drive. Install into engine. Rotate oil pump drive back to its original position and install hold-down clamp and bolt. Finger tighten bolt. Do not do a final tightening of bolt at this time.

Remove toothpick from housing.

Install sensor to oil pump drive. After installation, the CMP sensor should face rear of engine 0°.

Install 2 sensor mounting bolts and tighten to 2 Nm (15 in. Lbs.) Torque.

Connect electrical connector to CMP sensor.

If removed, install spark plug and ignition coil rail.

To verify correct rotational position of oil pump drive, the DRB scan tool must be used.

WARNING: When performing the following test the engine will be running. Be careful not to stand in line with the fan blades or fan belt. Do not wear loose clothing.

Connect DRB scan tool to data link connector. The data link connector is located in passenger compartment, below and to left of steering column.

Gain access to SET SYNC screen on DRB.

Follow directions on DRB screen and start engine. Bring to operating temperature (engine must be in "closed loop" mode).

With engine running at idle speed, the words IN RANGE should appear on screen along with 0°. This indicates correct position of oil pump drive.

If a plus (+) or a minus (-) is displayed next to degree number, and/or the degree displayed is not zero, loosen but do not remove hold-down clamp bolt. Rotate oil pump drive until IN RANGE appears on screen. Continue to rotate oil pump drive until achieving as close to 0° as possible. The degree scale on SET SYNC screen of DRB is referring to fuel synchronization only. It is not referring to ignition timing. Because of this, do not attempt to adjust ignition timing using this method. Rotating oil pump drive will have no effect on ignition timing. All ignition timing values are controlled by powertrain control module (PCM).

Tighten hold-down clamp bolt to 23 Nm (17 ft. Lbs.) Torque

Images (Click to make bigger)

Monday, September 18th, 2017 AT 6:05 PM