Thank you for the pics, they look clear.

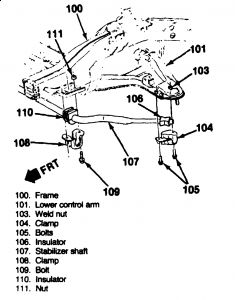

You have a SLA ( short-long-suspension arm) with the spring resting from the lower control arm, that make our problematic ball joint a load carrying one.

Damage to it could put more weight on the bearing as long as the problem is not fixed, so your friend is right about the bearings.

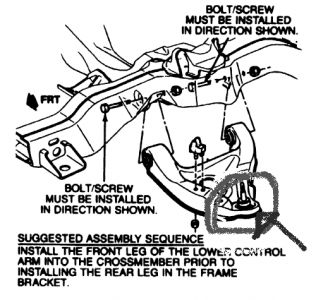

Here is the first thing to do for safety precaution:

-Reach across to jack the control arm from the opposit side of the vehicle. This will allow the jack to roll toward the inside of the vehicle as the control arm is lowered releasing spring pressure.

- remove the cotter pin from the ball joint nut and loosen the nut several turns.

-position the vehicle so that the coil spring is pushing on the ball joint. This will require lifting the vehicle or allowing its weight to rest on the wheels

- use a hammer to pound sharply on the steering knuckle on the outside of the tapper. This will deform the tapperand spring pressure will separate the ball joint from the steering knuckle.

If it does not work, use a pickle fork to separate the ball joint.

Tell me how far you have come.

Friday, November 27th, 2009 AT 11:31 PM