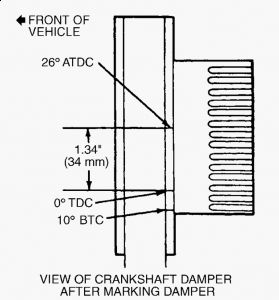

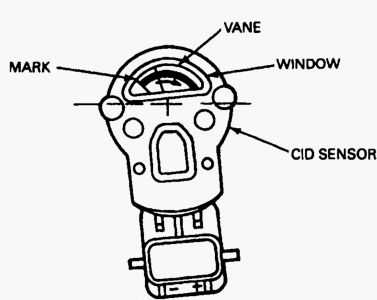

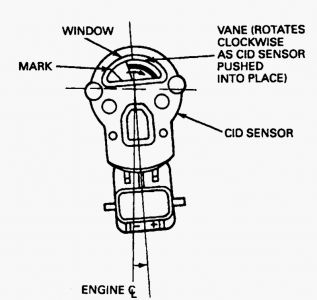

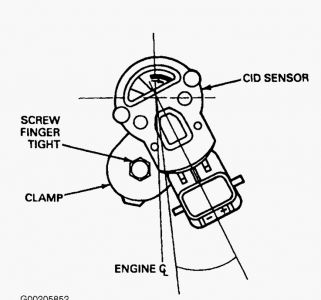

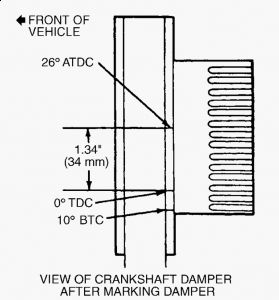

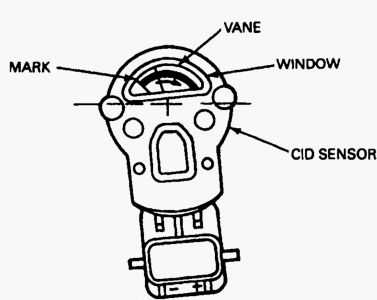

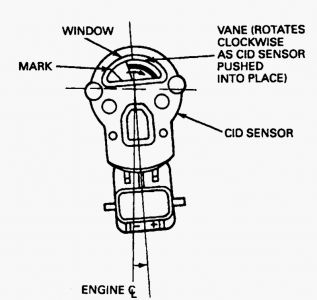

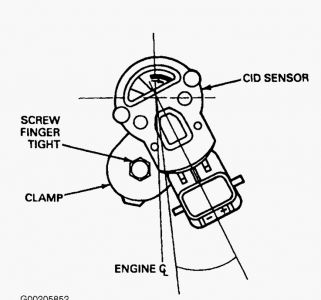

CAMSHAFT POSITION (CMP) SENSOR Removal (4.0L California) Position crankshaft to TDC of cylinder No. 1. Disconnect negative battery cable. Unplug harness connector from CMP sensor. Remove CMP sensor holdown and CMP sensor. Installation 1. Lubricate oil pump drive pinion, flange and O-ring. DO NOT get oil above mounting flange. 2. Rotate crankshaft until TDC mark on damper is accessible. Place a mark on the damper at 26 degrees After Top Dead Center 1.34 inches (34 mm) counterclockwise from TDC mark. See Fig. 3 . Rotate crankshaft to position No. 1 cylinder at TDC. Fig. 3: Marking Crankshaft Damper Courtesy of FORD MOTOR CO. 3. Align sensor rotor with trailing edge of vane lined up with short mark at the left hand side of the plastic window. See Fig. 4 . Position the sensor above its hole at right angles to the block rear face with wiring connector pointing rearward. Fig. 4: Aligning Sensor In Window Courtesy of FORD MOTOR CO. 4. Install assembled sensor and oil pump drive gear into engine. As assembly is pushed into place, sensor vane will rotate clockwise toward center of window. See Fig. 5 . Rotate sensor counterclockwise. Install clamp and screw finger tight. Rotate sensor back to position at right angles to back of block.See Fig. 6 . Fig. 5: Installing Sensor In Engine Courtesy of FORD MOTOR CO. Fig. 6: Location While Installing Clamp & Screw Courtesy of FORD MOTOR CO. 5. Connect CID Testing Wiring Harness (T94T-50-B) to sensor as follows: Ã Â Â Red harness wire to battery positive terminal. Ã Â Â Black harness wire to battery negative terminal. Ã Â Â White harness lead to voltmeter positive lead. Ã Â Â Voltmeter negative lead to battery negative terminal. Rotate engine 2 revolutions to take up slack in timing chain, and verify that No. 1 cylinder is on compression stroke. Continue to rotate crankshaft until 26 degree ATDC mark lines up with timing pointer. NOTE: Voltmeter will register battery voltage when sensor closes and6. While rotating sensor, note exact point where sensor switches from zero to battery voltage. Rotate sensor clockwise past switching point from battery voltage to zero volts. Rotate sensor counterclockwise and stop at exact point voltmeter switches from zero volts to battery voltage. Tighten CMP sensor hold down bolt to specification. See TORQUE SPECIFICATIONS . Disconnect testing harness and connect sensor harness. completes circuit. NOTE: Final movement to set sensor must be counterclockwise direction.

11/28/2009 ...

Didnt pinch crankshaft posion sensor wires did you?

SPONSORED LINKS

Sunday, May 17th, 2020 AT 11:31 AM