2004 Dodge Neon 4 cyl Two Wheel Drive Manual

I have a 2004 Dodge Neon SXT, 2.0 SOHC, Manual transmition. I have recently been having issues where The car will sputter out when driving, and the check engine light comes on. By sputter I mean, when I go to take off in first gear, I get up to about 2500 RPM, then it sputters like there is no fuel going through the lines. Switch gears, and again about 2500 RPM give or take, and will continue this for each gear. Or when it chooses to work correctly. Lets say I'm doing highway speeds, it will cut out, as if no fuel. Let off on the gas, and wait till I'm down to say 30 mph. Then kicks back in.

I was assuming maybe something with the fuel pump, or fuel filter. But apparently there is no filter on this car.

Currently the check engine light is off. But I decided to hook it up to the computer and analize through this method.

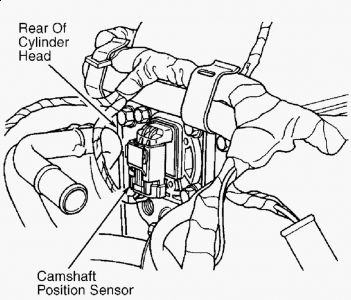

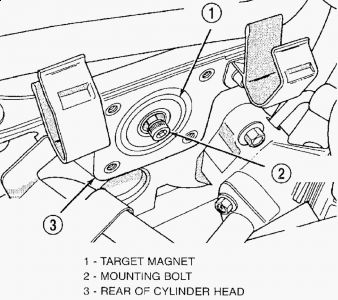

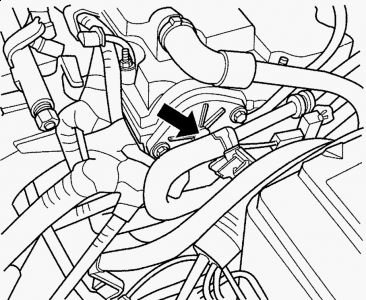

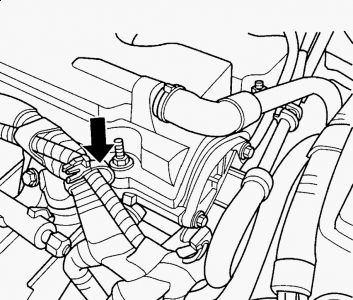

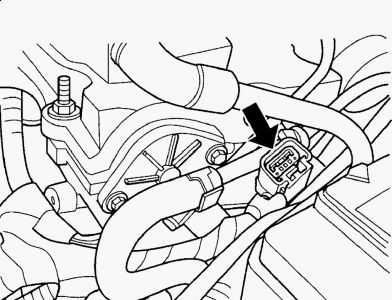

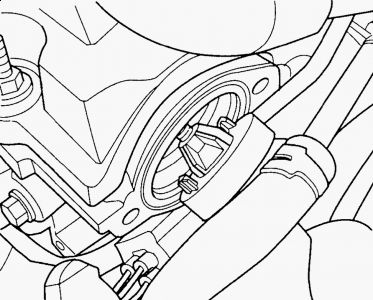

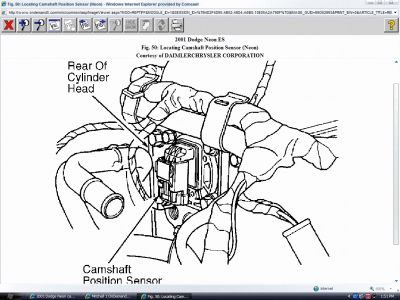

I came up with 2 codes that say the same thing. Camshaft Position Sensor Interupped.

I've located the part on the car. But haven't gone any further.

Could you Please advise me as to if this is the problem?

Wednesday, December 9th, 2020 AT 8:26 AM

(Merged)