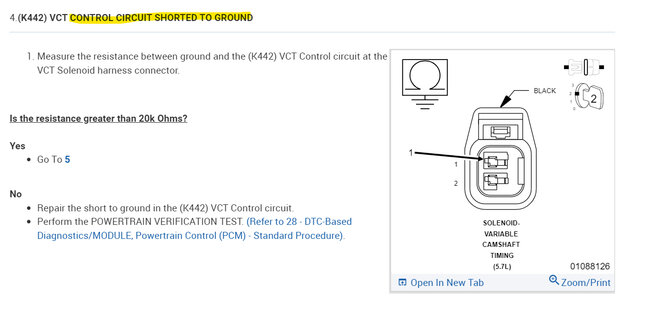

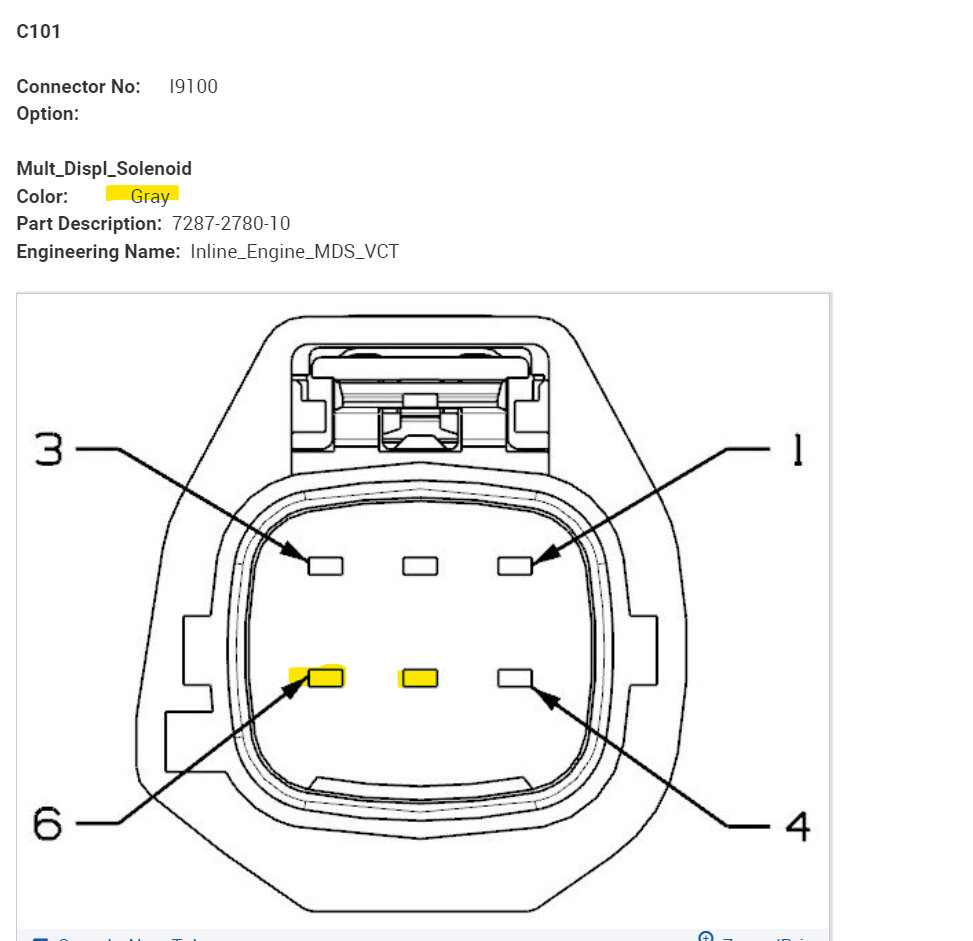

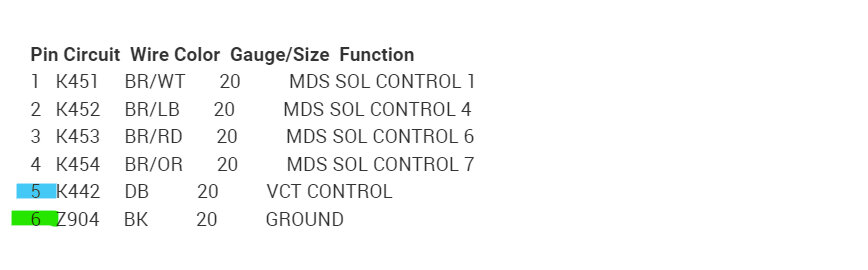

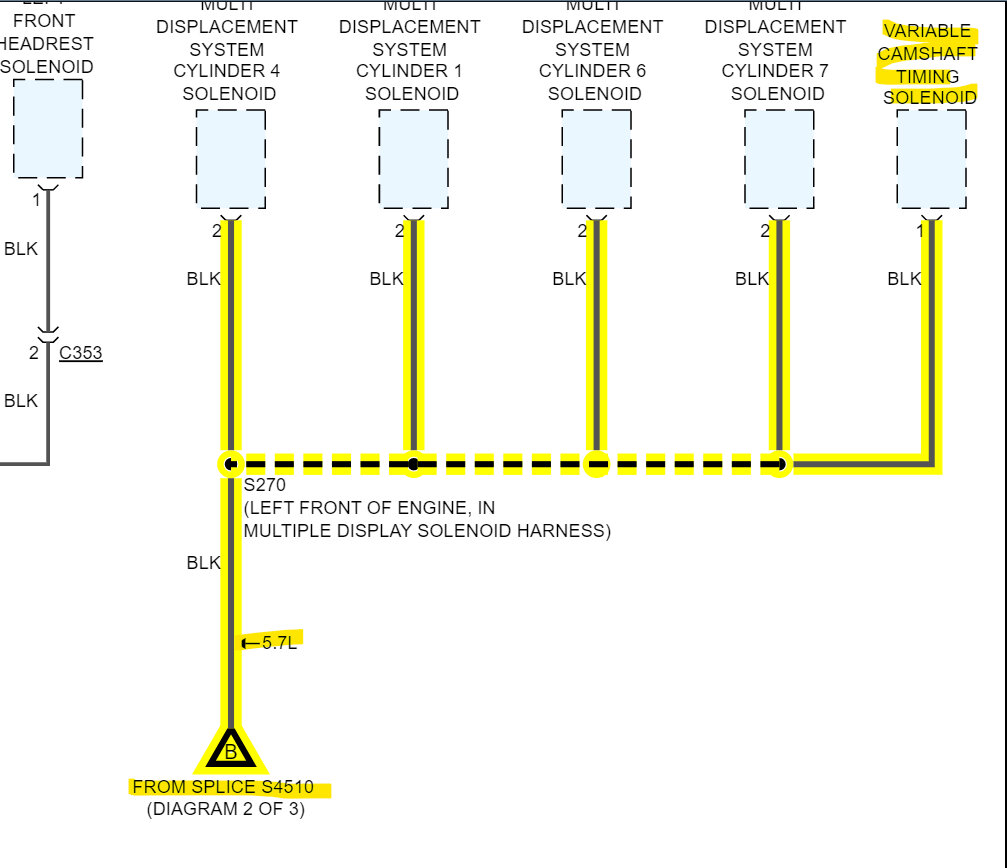

I replaced the alternator with a used one and put in a new AGM battery, started the car and was presented with a CEL. I put my Innova code reader on and got P0013: Exhaust Camshaft Position Actuator Circuit / Open Bank 1. I’ve been racking my brain to figure this out. I’ve pulled the intake manifold off and found bad/bare wires at the VVT solenoid, I repaired/mended the wires where it showed copper and ran continuities on both wires from before and after my mended spots, I then put the manifold back together. Started the car and got the same code. I pulled the manifold back off and pulled the VVT solenoid out. I ran a continuity test on the solenoid about 5 times and it was flat line, so I changed the multimeter to duty cycle and tested the solenoid, it was flat. I tested yet again on continuity, and it registered, every test after has registered with continuity. I put the solenoid to 12v to check for actuation, it actuates but I’m not sure if it’s fully opening. I left the whole thing where it is and ordered a new solenoid and jumper harness. I’m waiting on the new harness to arrive before I do anything further.

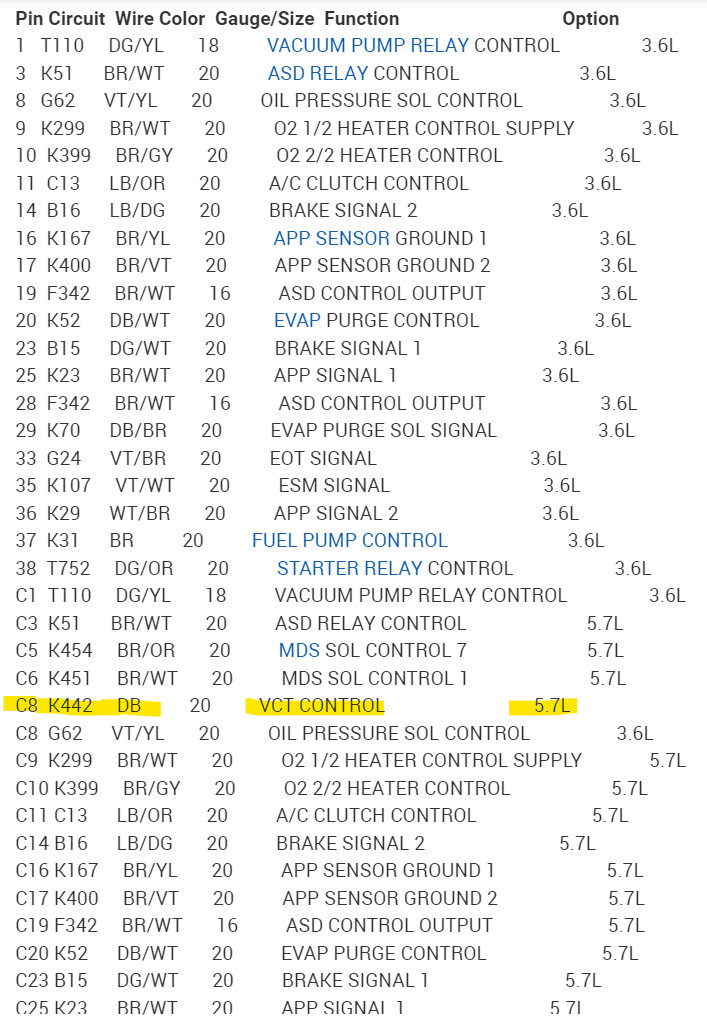

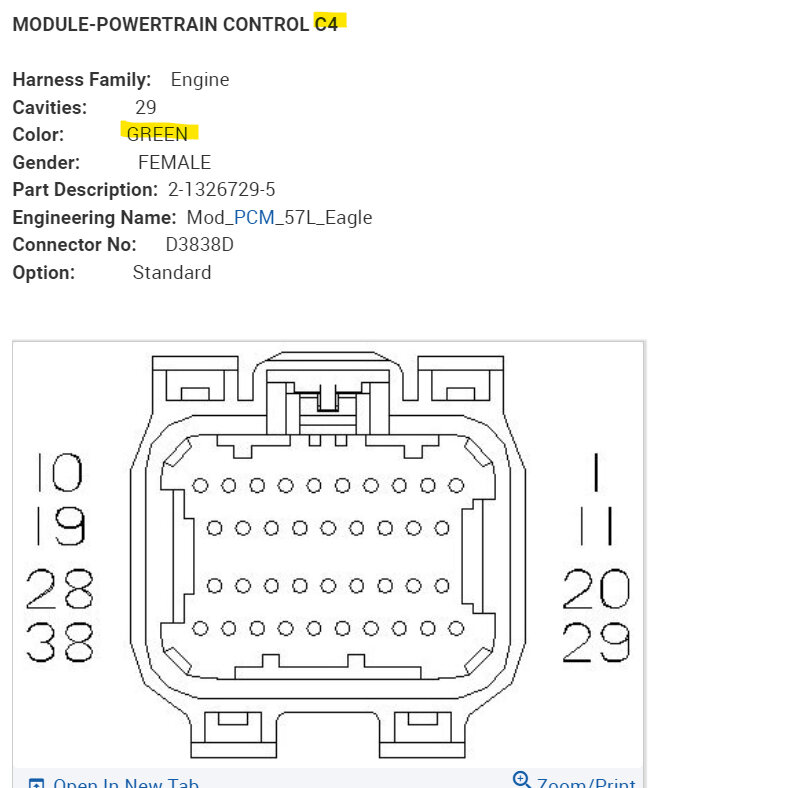

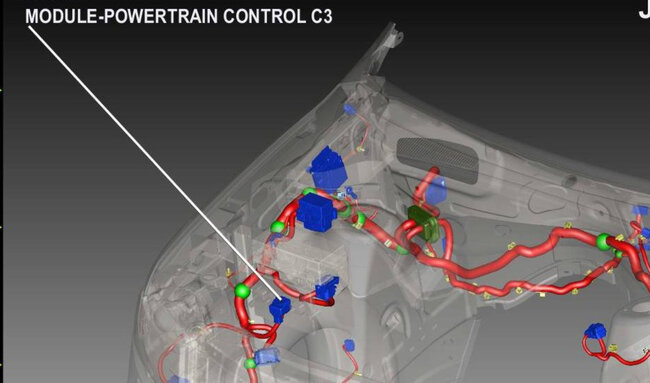

My question is how do I identify all the wires coming out of the PCM? It has 4 big plastic connectors coming out and lots of wires in each.

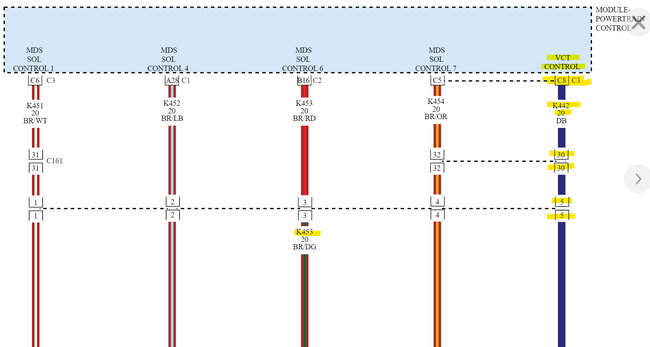

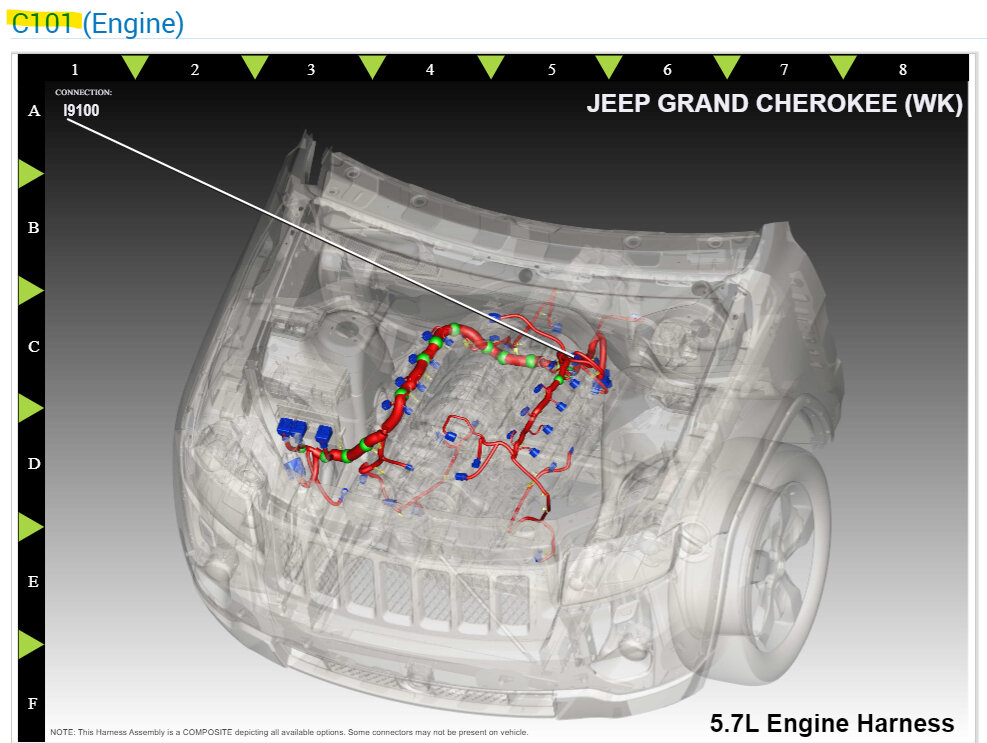

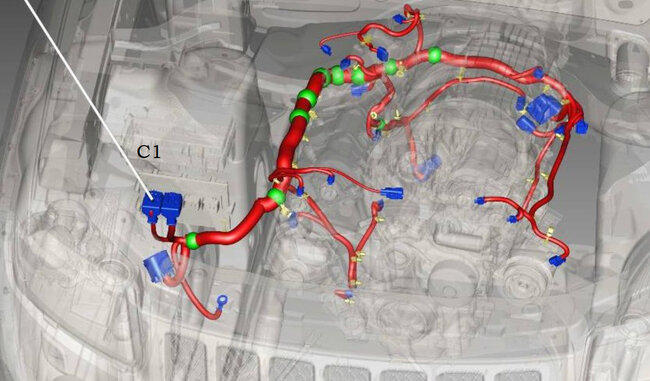

I have sourced a flow chart diagram of the engine electrical, but this doesn’t help me to single out the wires at the PCM side. My worry is that it’s a burn/broken wire further down in the jacket where I can’t see or reach, but if I can pinpoint the wires at the PCM side, I can in theory jump past the bad wire with a fresh wire, therefore saving thousands in repairs and having my vehicle running again.

SPONSORED LINKS

Saturday, May 27th, 2023 AT 11:23 AM