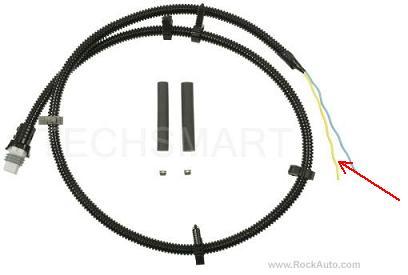

Went through changing wheel bearings on both front wheels but this did not solve the problem. Finally for the right wheel garage guy changed the connector on the Front right wheel and this solved the problem for a while. Started again this time with the left wheel, changed the bearing there and worked ok for a few weeks and back again the problem came.

Now I have checked the connector at the left wheel, managed to adjust the harness so there is no pulling on the connector at the bearing when turning and have secured the harness with additional ties. The problem went away but came back within two weeks. Just to make sure it was the same wheel, removed the connector again and reconnected, again initially it works fine but problem returns within 10-12 days. The wire in the harness is fine not broken anywhere so its strange after removing and putting back the connector it works for a few days but problem comes back after that, Also Abs light comes on more frequently as time goes by sometimes the lights come on before even moving out of park at other times when driving on a straight stretch with no apparent cause to mal function.

So it seems after removing and reconnecting the abs sensor the lights go away and it drives Normal but problem comes back after a while.

Could it be moisture getting into the contacts and causing it to malfunction, though you would think after they dry out the problem should go away but does not, unless as I mentioned disconnecting and reconnecting the abs sensor at the wheel.

Would appreciate any help and thanx in advance

SPONSORED LINKS

Friday, May 4th, 2012 AT 6:37 PM