Here is sprocket diagrams and install procedure

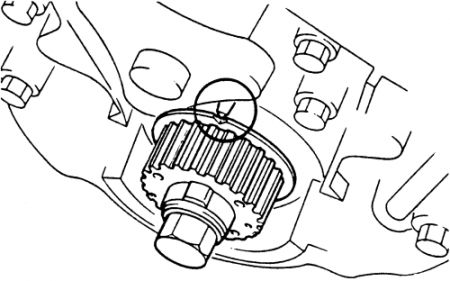

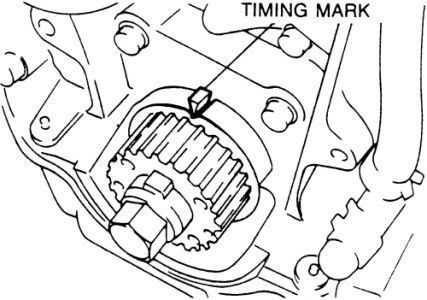

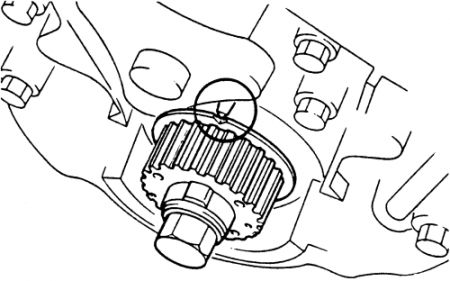

Crankshaft sprocket timing marks for the 1990-94 1.8L DOHC engine

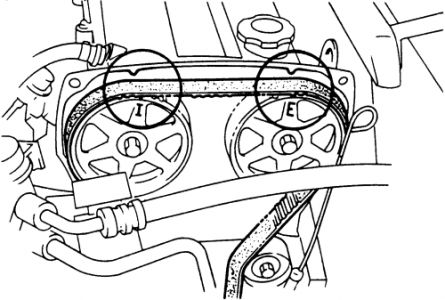

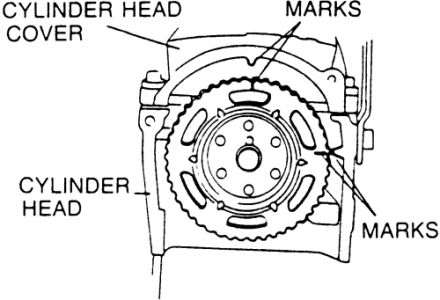

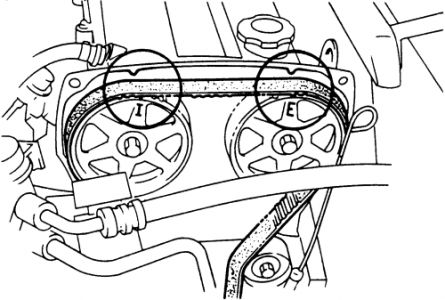

Camshaft sprocket timing marks for the 1990-94 1.8L DOHC engine

If removed, install the idler pulley and tighten the bolt to 38 ft. lbs. (52 Nm).

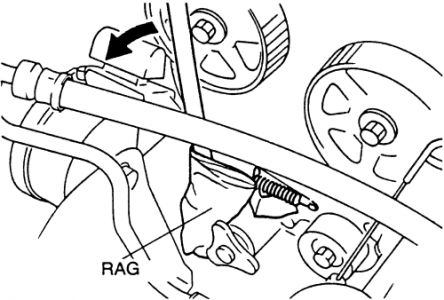

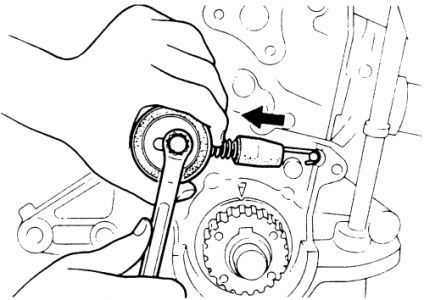

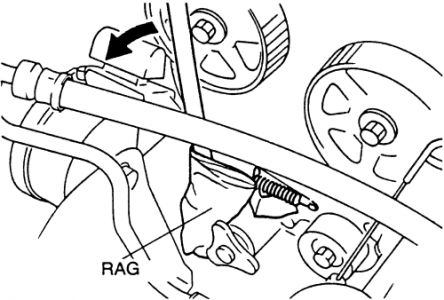

Install the tensioner and tensioner spring. Pry the tensione outward and temporarily tighten the tensioner lockbolt with the tensioner spring fully extended.

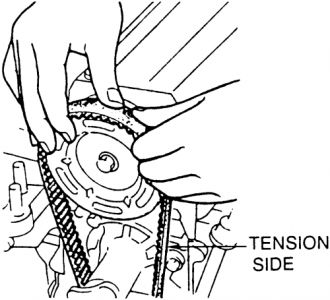

Pry the tensioner pulley (protect it with a rag) outward to fully extend the spring, then tighten the bolt to hold it in position

Make sure the crankshaft sprocket timing mark is aligned with the mark on the oil pump housing and the camshaft sprocket timing marks are aligned with the marks on the seal plate.

Install the timing belt so there is no looseness at the idler pulley side or between the camshaft sprockets. If reusing the old belt, make sure it is installed in the same direction of rotation.

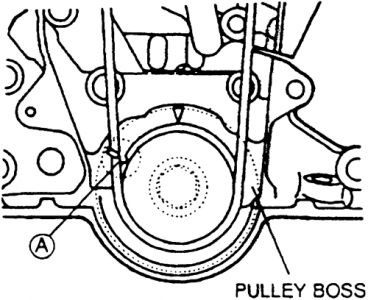

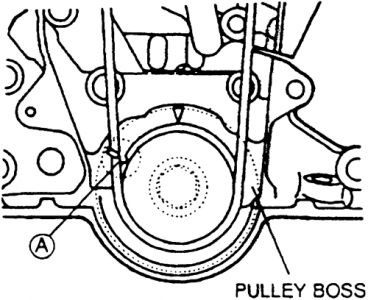

On 1993-94 vehicles, temporarily install the pulley boss and lockbolt.

Turn the crankshaft 2 turns clockwise and align the crankshaft sprocket timing mark. On 1993-94 vehicles, face the pin on the pulley boss upright. Make sure the camshaft sprocket timing marks are aligned.

Turn the crankshaft 15/6 turns clockwise and align the crankshaft sprocket timing mark with the tension set mark for proper belt tension adjustment. On 1992-94 vehicles, remove the lockbolt and pulley boss.

To properly set tension on the belt, turn the crankshaft 15/6 turns and align the tension set mark with the crankshaft sprocket

Make sure the crankshaft sprocket timing mark is aligned with the tension set mark. Loosen the tensioner lockbolt and allow the spring to apply tension to the belt. Tighten the tensioner lockbolt to 38 ft. lbs. (52 Nm).

On 1993-94 vehicles, install the pulley boss and lockbolt.

Turn the crankshaft 2-1/6 turns clockwise and make sure the timing marks are correctly aligned.

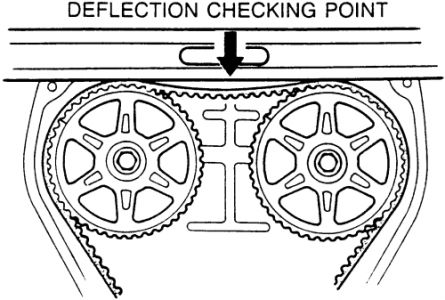

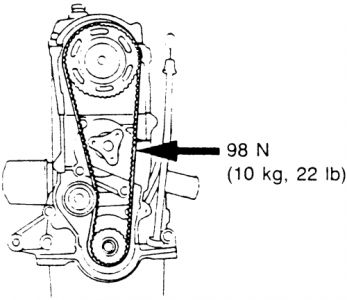

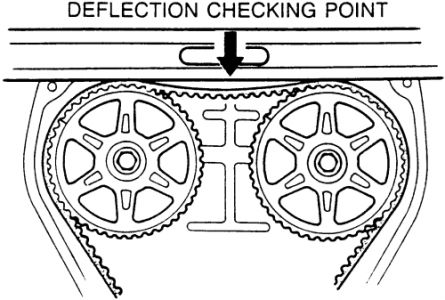

Check the deflection of the timing belt to ensure proper tension has been set on the belt

Apply approximately 22 lbs. pressure to the timing belt at a point midway between the camshaft sprockets. The belt should deflect 0.35-0.45 in. (9.0-11.5mm).

On 1993-94 vehicles, hold the boss with a suitable tool and tighten the lockbolt to 123 ft. lbs. (21 Nm).

Install the timing belt covers and tighten the bolts to 95 inch lbs. (11 Nm).

Install the engine oil dipstick.

Install the spark plugs and connect the spark plug wires.

Install the timing belt inner guide plate, if equipped. Make sure the dished side of the plate faces away from the timing belt. Install the outer guide plate, if equipped.

Install the crankshaft pulley and tighten the bolts to 13 ft. lbs. (17 Nm).

Install the water pump pulley and the accessory drive belts. Adjust the belt tension.

Install the engine side or undercover, as necessary. Connect the negative battery cable.

Start the engine and check for proper operation. Check the ignition timing

Saturday, June 29th, 2019 AT 4:16 PM

(Merged)