An engine starter is constructed as a high torque, high amperage 12 volt motor

fitted with an electrical solenoid and Bendix gear which is used to rotate an engine

between 85 and 150 rpm's to begin the combustion process (start the engine). A starter

motor's components include a main outer housing which contains positive and negative

pole magnets, an armature that contains windings, and a brush set which is used

to contact the armature and transfer electrical current and a solenoid which acts

as the high amperage switch. Most starter motors are mounted underneath the engine,

either on the left or right side, some are mounted under the intake manifold.

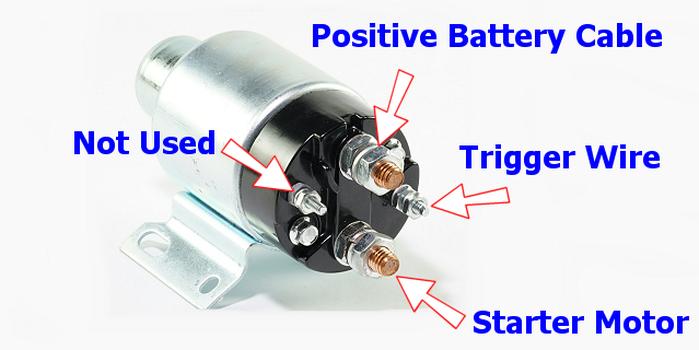

The electrical device that controls the starter motor is the solenoid. In the

image below you can see how the starter and solenoid is wired to the battery and

ignition switch. The top lug is where the positive battery cable is connected, the

trigger terminal is sent from the ignition switch, the lower larger terminal is

connected to the starter motor when the solenoid is activated.

Here is an image of the starter armature which is the internal part of the starter

that spins to create the starter's purpose. The arrows show the roller bearings

on either side to support the unit while inside the starter housing.

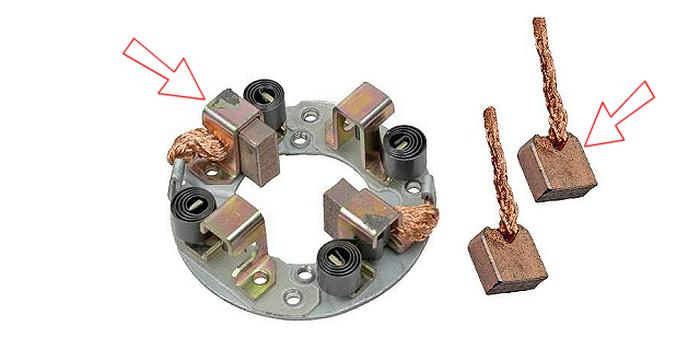

A brush set rides against the armature using spring pressure to produce a connection

for the electrical power to travel through, this is what makes the armature spin.

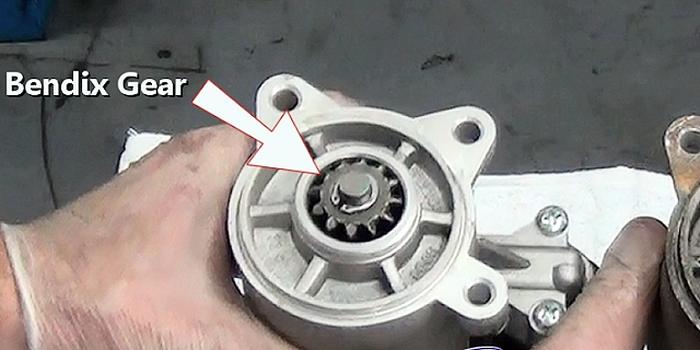

The bendix gear is designed to extend from the starter motor when in use, and

retract back into the housing once the engine starts. This small gear meshes with

engine via the flywheel (manual

transmission) or flex plate (automatic

transmission) and is designed with a one way clutch which enables the starter motor

to "freewheel" as the engine starts while forcing the gear back into the starter

motor housing and away from the flywheel.

Questions?

Our certified technicians are ready to answer starter questions for free. We hope you saved money and learned from this guide. We are creating a full set of car repair guides. Please subscribe to our 2CarPros YouTube channel and check back often for new videos which are uploaded regularly.