The first thing to suspect is the drum is worn beyond the legal limit, especially if it was grinding. There is always a published maximum diameter the drum can be machined to, and another slightly larger diameter it can be allowed to wear to. Those are called the "machine to" spec. And the "discard" spec. You'll need a special drum micrometer to measure them accurately. Don't waste your money on buying one. Every auto parts store that offers drum and rotor machining will have one and they will check your drums for free. No reputable mechanic will machine a drum or rotor beyond the machine-to spec to try to save it. That can leave them open to a lawsuit or liability issues. For that reason, all independent repair shops that offer brake service will have this gauge too.

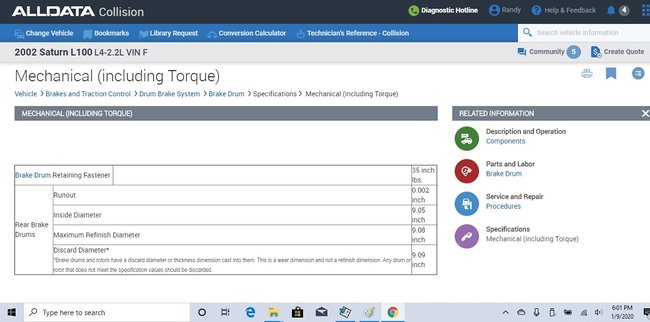

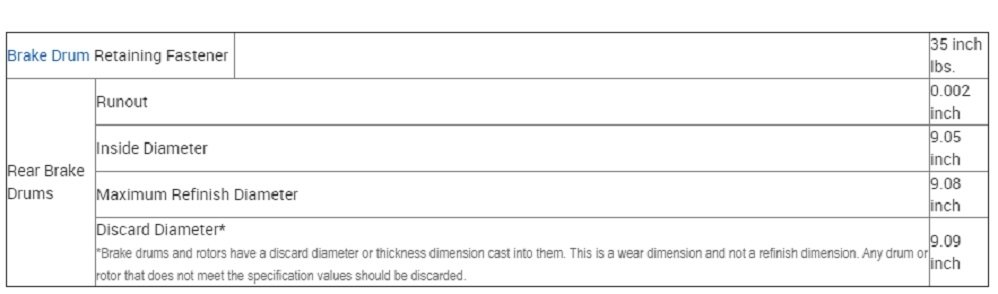

The second chart below is just a blown-up copy to make it easier to read. While it isn't listed this way, drums and rotors are measured to the thousandth of an inch. Yours started out at 9.050" when they were new, and they can be machined to 9.080", which is only 0.015" per side. That is a fairly standard amount although many larger drums can be machined quite a bit more. Your drums can be allowed to wear another 0.010" to a total of 9.090". Once they get bigger in diameter than that, the shoes' diameter will prevent them from making full contact until the center of the lining wears down a lot. That leaves you with a front-to-rear brake balance considerably different than what was carefully designed in.

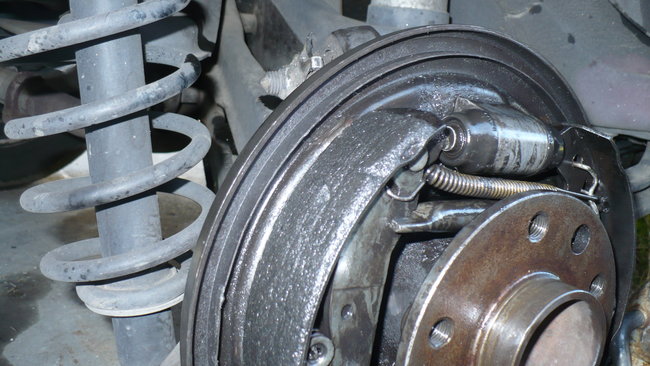

It takes a lot more wear on the drum to allow a piston to pop out of the wheel cylinder. A better suspect is the shoe frame is moving out far enough to let it drop down into the "labyrinth seal". That's the curved groove around the outer edge of the backing plate. The drum has a matching groove. When those are assembled, they form somewhat of a seal that prevents water from splashing in.

Look at where the piston is sitting in relation to the shoe. If the piston is away from the backing plate, meaning you can see it in front of the end of the shoe it's supposed to push on, the shoe has dropped into the groove and is allowing the piston to bypass it. If the piston is behind the shoe, the better suspects are worn shoe hold-down hardware or weak shoe return springs. All of those springs and hardware are available as a complete kit for the entire axle.

Your comment about the old shoes burning up concerns me. There's two things I would be looking for. The first is if a parking brake cable is stuck in the partially-applied position. Given the age of the vehicle, if you live in a northern climate like I do where they throw a pound of salt on an ounce of snow, rusted cables are pretty much a certainty unless they've been replaced previously. A stuck cable will also prevent the self-adjuster from operating. Over time, instead of adjusting closer to the drum, the shoes will have to move out with a longer stroke to reach the drum. With sufficient wheel cylinder wear, that can allow the piston to twist enough for the shoe to slip off the end. Once that happens, there's nothing to hold the piston from being pumped out when you press the brake pedal.

My worse fear is when the brake fluid is contaminated with a petroleum product such as engine oil, transmission fluid, power steering fluid, penetrating oil, or axle grease. Those will cause all rubber parts that contact the brake fluid to swell and become soft and mushy. The first thing that usually happens is the rubber lip seals in the master cylinder grow past the fluid return ports, then the brake fluid is trapped and can't release back into the reservoir. As the disc brake pads heat up from staying applied, the heat migrates into the brake fluid. The fluid expands, and since it can't get back to the reservoir, it applies the brakes harder and harder, and they get hotter and hotter. We customarily see this with overheating front brakes, and not so much with rear drum brakes, but it can affect both axles. I think you would have noticed other problems or symptoms before now.

Your self-adjuster works by spreading the tops of the shoes further apart as the linings wear. With this design, the pistons work their way out of the wheel cylinders, and that leaves them prone to problems caused by overly-worn drums and linings. If the new drums and shoes don't solve this, try to post some photos, then we'll see if we can figure out what is happening.

Be sure to use a click-type torque wrench on the lug nuts. Torque them all to 46 foot-pounds first, then to 92 foot-pounds. Please keep us updated on your progress.

Images (Click to make bigger)

Thursday, January 9th, 2020 AT 4:52 PM