"Ckt" is "circuit". When you have a diagnostic fault code, they always refer to the entire circuit, never just a single part. In this case, you're testing a solenoid along with all of the wiring, at the same time. When you get acceptable results, you're done, and you can move on. When you get an open circuit, meaning an infinite reading, you need to narrow it down to a break in a wire, a corroded connector terminal, an open solenoid coil, or, as I often do, a bad connection of the meter's probe.

When testing a solenoid circuit, a typical resistance reading will be around one or two ohms, (almost a dead short, meaning 0 ohms). There will always be a little resistance in the wires, and in your meter's leads. Don't get excited if you find six to eight ohms. It's the open circuit you're looking for. "Open" means there's a break somewhere. Resistance values can always go higher and higher, but if you're using a digital volt / amp / ohm meter, 20 meg ohms, (20 million) is the highest most meters will read. LONG before you get anywhere close to that, the circuit will not work because not enough current can get through. Even though the actual amount of resistance can keep going higher, we reach the point where for all practical purposes, it's like there is a break in the circuit, and we call that "infinite".

My concern now is if you're finding two solenoid coils that are open, how likely is that to occur at the same time? If I were doing those tests and found two open coils, I'm fairly confident I would find my meter probes had a bad connection someplace, or a plug with multiple wires was loose or unplugged.

To set your mind at ease, you will not damage a digital ohm meter by applying 12 volts to it. They can withstand that. That's not the case with the older-style pointer-type meters. You're right though that we take resistance readings in circuits that are not powered up.

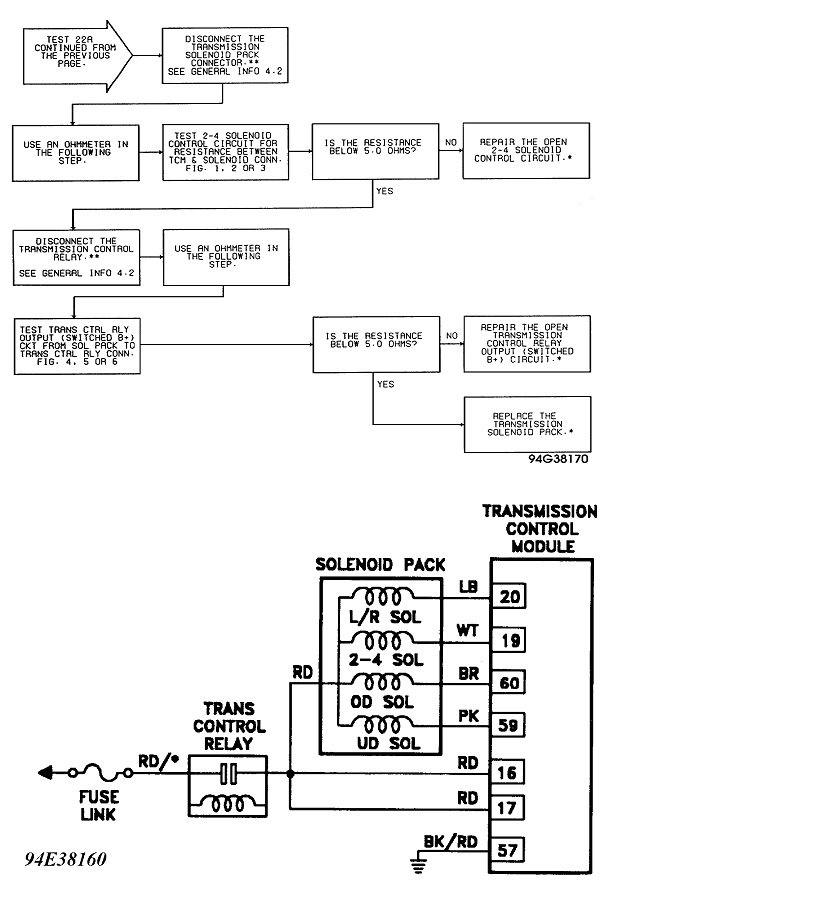

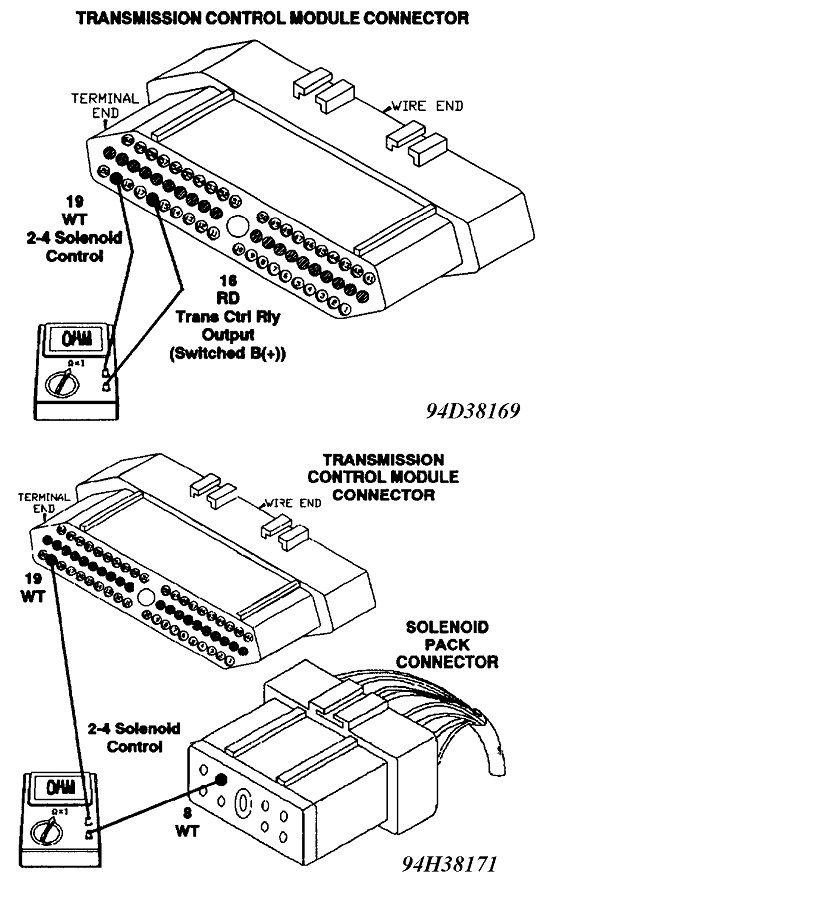

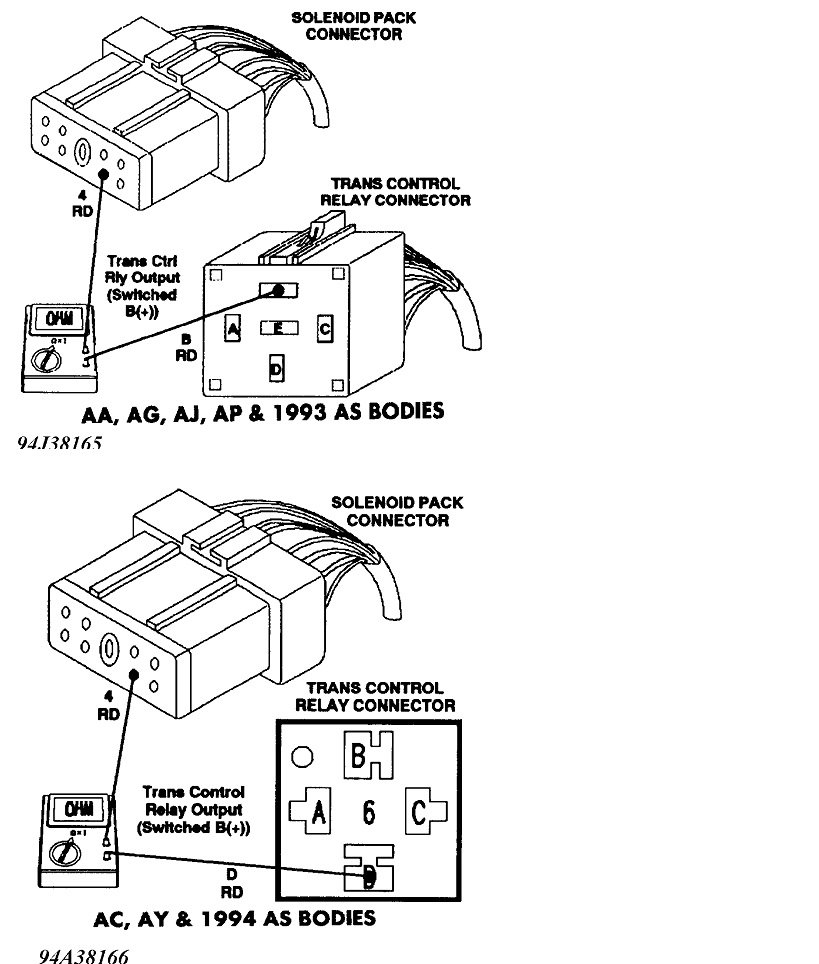

To add to the confusion, when the procedure tells you to probe a circuit, it is a test designed around Chrysler's DRB3 scanner. That has a volt / ohm meter built in but I've never used it. I have that scanner for my personal vehicles, but I only use these test procedures to direct me to the correct terminals in a connector, then I use my regular ohm meter. When they show the wiring diagram in one of these diagnostic manuals, they only show the wires specific to the circuit in that test. I like to use the regular service manual because it shows everything at once. That works best when I'm already familiar with the circuit. The steps in the diagnostic manuals are better for people who don't understand how the entire system works, and they aren't interested in learning that. The problem with this approach is if there are 20 steps needed to insure you will be led to the cause of the problem, you are guaranteed you'll have to start at step one, and go through every step. That can be very time-wasting for a mechanic experienced with this circuit, but it can be a life-saver for someone who has never seen this circuit before or worked on it.

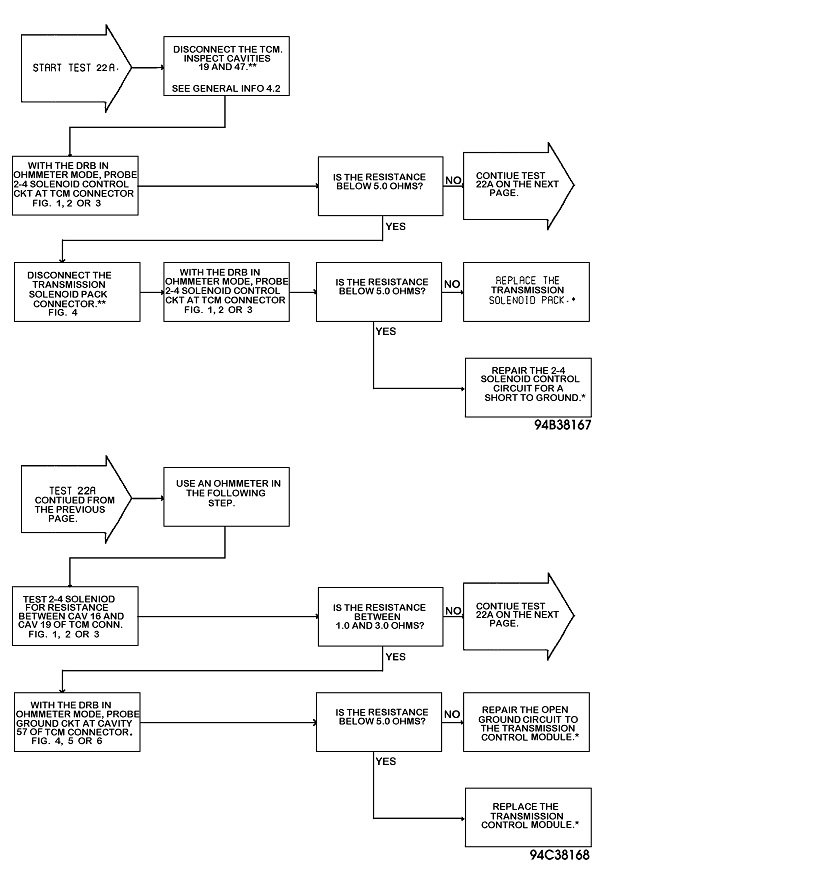

I just read test 22A. The DRB3 scanner already has a ground wire in its cable. What they're having you do is use the scanner's probe to test for continuity to ground on one of the solenoid's wires. That is to test if either wire is shorted to ground, as in a bare wire touching metal engine parts. You don't need to test each wire. If one is grounded, the other one will read as grounded too, through the solenoid. With your ohm meter, place one probe on the terminal specified, and the other probe on a paint-free metal part of the car. The way I like to do it is to place one on the car first, with a clip lead so I don't have to hold onto it, then I place the second probe also on the body, but somewhere else. You should get a reading of 0 ohms, or perhaps a few ohms. That simply proves that both probes are making good contact and are not sitting on some surface dirt or corrosion. Scratch the connections a little if necessary to get a low reading. By the way, the ohm meter should be on the lowest scale to provide the best accuracy. For almost all digital meters that is the 200 ohm scale. That means it will read any resistance value between 0 and 199 ohms. Now that I see the 0 ohms, I have the confidence to continue, knowing the ground probe is making good contact. From then on it's up to the other probe to make good contact, and when it does, I'll get my reading.

You don't want any part of this circuit to be grounded, and if it is not, you will get an infinite reading, which on this scale means it's over 200 ohms. You can switch to a higher scale if you want to momentarily, but you should still see an infinite reading.

The later test is measuring resistance between the two wires going to one of the solenoids. That goes back to the entire "circuit", and my first paragraph. Since you need two meter probes, this is why they're telling you to use a separate ohm meter. That second probe in the DRB3 is in its connecting cable and is hooked to the body sheet metal, electrically. The body, (ground) is not part of this test and is why it can't be done with the DRB3.

I didn't read far enough to see if they want you to take a voltage reading. If they do, 99 percent of them are a voltage at a point in a circuit, in relation to a common point, which simply means ground. Since the DRB3 is already grounded, you just need its single probe to take the reading. When using your voltmeter, use the 20-volt scale, put the black probe on the body, and measure at the point specified with the red probe. If you switch the probes, you'll still get the right value, but with a minus sign.

As long as I'm at it, there is one more thing I should point out. Once you become familiar with measuring the solenoid coils, you might want to measure other things with coils of wire in them. That includes the primary and secondary parts of an ignition coil, the coil in a relay, an injector, or a motor. When current flow is stopped abruptly from flowing through a coil of wire, the collapsing electromagnetic field generates a huge voltage spike. That is very desirable and necessary in an ignition coil, but spikes can damage computers. With motors and injectors, the control circuitry either isn't computer-controlled, or, like with transmission solenoids, the circuitry is so robust, it is relatively immune to those spikes. That's not the case with relays. Their voltage spikes are smaller, but have been known to cause computers to fail or to lock up. To prevent this, almost all relays, except for those in GM vehicles, have a diode across the coil of wire. A diode is a one-way valve for electrical current flow. It is placed across the coil backward, or "reverse biased", so it's like it isn't even there. However, when current flow to that coil is stopped, and the collapsing magnetic field generates a voltage spike, that voltage is the opposite polarity and that puts the diode in the circuit "forward-biased" momentarily. That effectively shorts out the voltage spike and makes it harmless. My reason for sharing this wondrous information is with a few ohm meters, their internal batteries are strong enough to cause the diode to turn on and measure what might appear to be a short. Let me explain.

Most digital meters have a diode test right next to the ohms ranges. You can't measure a diode while it's in a relay because for this test, the coil is shorting it out. If you snip one end of the diode, it is no longer in the circuit and can be measured. The "cathode" has a colored band denoting its polarity, but for this sad story, that is not important. What you should find is with the meter leads connected one way, the meter will read infinite, or open circuit. When you switch the meter leads, you will see a value somewhere between, ... Oh, ... 400 to 700. When any diode is forward biased, it takes a small amount of voltage that must be reached before current starts to flow, and it acts like a short from then on. That voltage is roughly 0.5 volts, give or take a little. That is the voltage the meter is measuring. It is reading to three decimal places, so you might see "632", meaning when 0.632 volts is reached is when current will start to flow. As a further point of interest, high-power diodes, like those used in alternators, have a lower turn-on voltage, typically around 400 millivolts. Small signal diodes, like those used in relays and in computer circuits, typically will be around 650 to 750 millivolts.

The exact value is irrelevant, but it gets even easier when testing a diode. If a diode is shorted, it will act like a piece of wire. Wire has no polarity and as such, the meter will read "0" regardless of which way you connect the meter leads. If it reads shorted one way, there is no need to waste your time measuring it the other way. Next, if you read a good voltage one way, as in "647", the diode has to be good. It isn't open, and it can't be shorted. No need to measure it the other way.

The only time you have to worry about the diode in a relay is when you're building custom circuits. The generic relay will activate with the correct voltage applied across its coil, regardless of polarity. It's when you add the diode that polarity must be observed. The times I've connected one backward, there was nothing to limit current flow through the diode once it turned on, and that excessive current caused it to short, let out the smoke, and from then on it burned open. Once it was open, it was like it wasn't even there. The relay would again operate normally, but there was no diode to suppress those voltage spikes.

I'll be back tomorrow to see if you've made any progress.

Friday, December 2nd, 2016 AT 9:15 PM