To install:

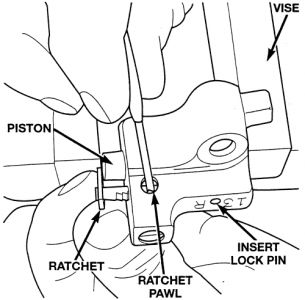

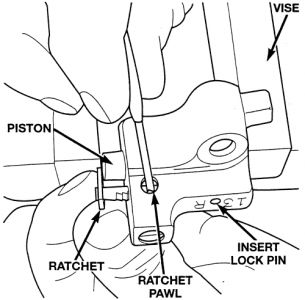

Using a vise, lightly compress the secondary chain tension-er piston until the piston step is flush with the tension-e body. Using a pin or suitable tool, release ratchet pawl by pulling pawl back against spring force through access hole on side of tension-er. While continuing to hold pawl back, Push ratchet device to approximately 2mm from the tension-er body. Install special tool 8514 lock pin into hole on front of tension-er. Slowly open vise to transfer piston spring force to lock pin.

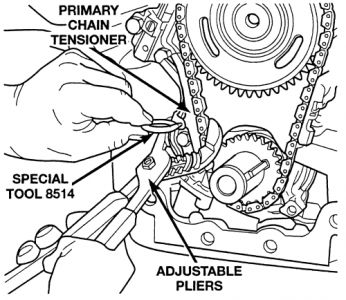

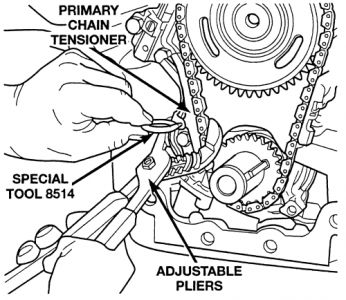

Position primary chain tension-er over oil pump and insert bolts into lower two holes on tension-er bracket. Tighten bolts to 250 inch lbs. (28 Nm).

WARNING:

Over-tightening the tension-er arm Torx � bolt can cause severe damage to the cylinder head. Tighten bolt to specified torque only.

Install right side chain tension-er arm. Apply Mopar � Lock N, Seal to Torx � bolt, tighten bolt to 150 inch lbs. (17 Nm).

NOTE:

The silver bolts retain the guides to the cylinder heads and the black bolts retain the guides to the engine block.

Install the left side chain guide. Tighten the bolts to 250 inch lbs. (28 Nm).

WARNING:

Over-tightening the tension-er arm can cause severe damage to the cylinder head. Tighten bolt to specified torque only.

Install left side chain tension-er arm. Apply Mopar � Lock N, Seal to bolt, tighten bolt to 150 inch lbs. (17 Nm).

Install the right side chain guide. Tighten the bolts to 250 inch lbs. (28 Nm).

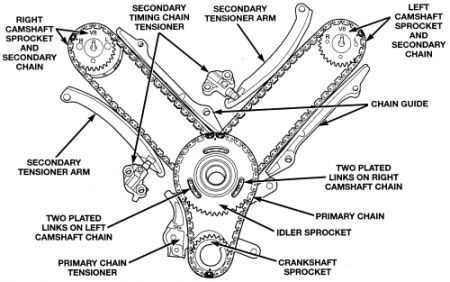

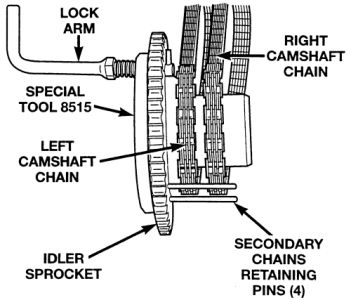

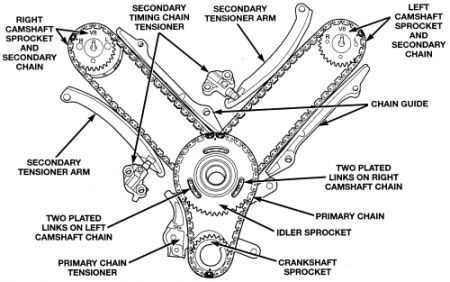

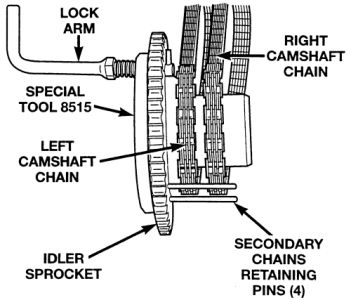

Install both secondary chains onto the idler sprocket. Align two plated links on the secondary chains to be visible through the two lower openings on the idler sprocket (4 o'clock and 8 o'clock). Once the secondary timing chains are installed, position special tool 8515 to hold chains in place for installation.

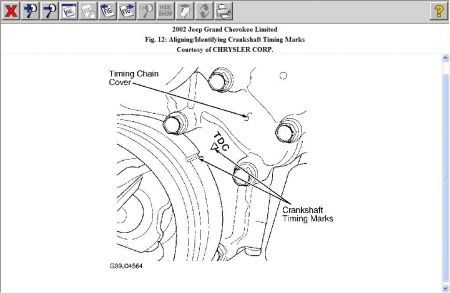

Align primary chain double plated links with the timing mark at 12 o'clock on the idler sprocket. Align the primary chain single plated link with the timing mark at 6 o'clock on the crankshaft sprocket.

Lubricate idler shaft and bushings with clean engine oil.

Install all chains, crankshaft sprocket, and idler sprocket as an assembly. After guiding both secondary chains through the block and cylinder head openings, affix chains with a elastic strap or the equivalent, This will maintain tension on chains to aid in installation.

NOTE:

It will be necessary to slightly rotate camshafts for sprocket installation.

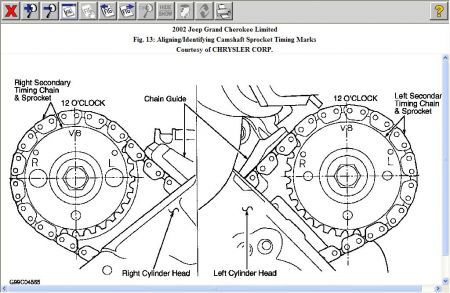

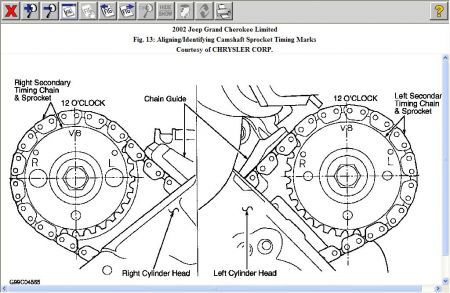

Align left camshaft sprocket "L" dot to plated link on chain.

Align right camshaft sprocket "R" dot to plated link on chain.

WARNING

Remove excess oil from the camshaft sprocket bolt. Failure to do so can result in over torque of bolt resulting in bolt failure

.

Remove Special Tool 8515, then attach both sprockets to camshafts. Remove excess oil from bolts, then Install sprocket bolts, but do not tighten at this time.

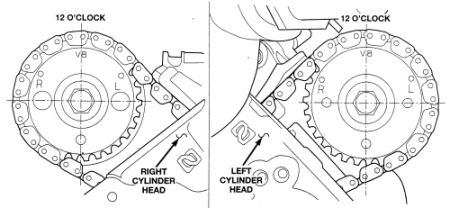

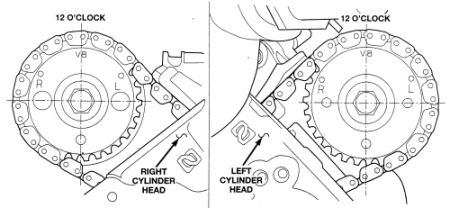

Verify that all plated links are aligned with the marks on all sprockets and the "V8" marks on camshaft sprockets are at the 12 o'clock position.

WARNING

Ensure the plate between the left secondary chain tension-er and block is correctly installed.

Install both secondary chain tension-er. Tighten bolts to 250 inch lbs. (28 Nm).

NOTE

Left and right secondary chain tension-ers are not common.

Before installing idler sprocket bolt, lubricate washer with oil, and tighten idler sprocket assembly retaining bolt to 25 ft. lbs. (34 Nm).

Remove all locking pins from tension-ers. WARNING

After pulling locking pins out of each tension-er, do not manually extend the tension-er(s) ratchet. Doing so will over tension the chains, resulting in noise and/or high timing chain loads.

Using special tool 6958, Spanner with adaptor Pins 8346, tighten left and right. camshaft sprocket bolts to 90 ft. lbs. (122 Nm).

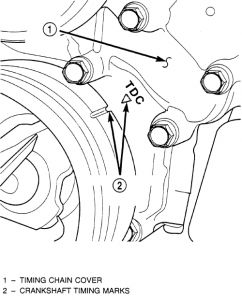

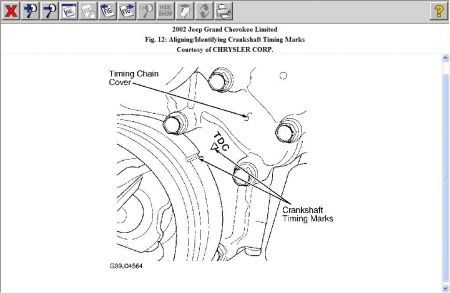

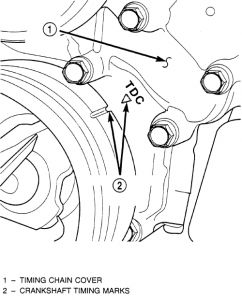

Rotate engine two full revolutions. Verify timing marks are at the following locations:

primary chain idler sprocket dot is at 12 o'clock

primary chain crankshaft sprocket dot is at 6 o'clock

secondary chain camshaft sprockets "V8" marks are at 12 o'clock

Lubricate all three chains with engine oil.

After installing all chains, it is recommended that the idler gear end play be checked. The end play must be within 0.10-0.25mm (0.004-0.010 in.). If not within specification, the idler gear and idler shaft must be replaced.

WARNING

Do not use oil based liquids to clean timing cover or block surfaces. Use only rubbing alcohol, along with plastic or wooden scrapers. Use no wire brushes or abrasive wheels or metal scrapers, or damage to surfaces could result.

Clean timing chain cover and block surface using rubbing alcohol.

WARNING:

The 4.7L can use a special RTV sealer instead of a carrier gasket to seal the timing cover to the engine block, from the factory. For service repairs, Mopar � Grey Engine RTV must be used as a substitute, if RTV is present. If the front cover being used has no provisions for the water passage O-rings, then Mopar � Grey Engine RTV must be applied around the water passages.

Inspect the water passage O-rings, if equipped for any damage, and replace as necessary.

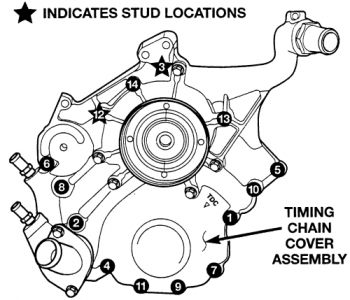

Apply Mopar � Grey Engine RTV sealer to the front cover following the path above, using a 3 to 4mm thick bead.

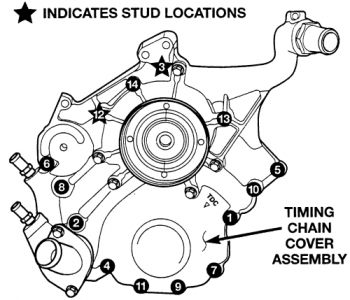

Install cover. Tighten flange head fasteners in sequence as shown in to 43 ft. lbs. (58 Nm).

Install the A/C compressor and generator.

Install crankshaft damper.

Install accessory drive belt tension-er assembly. Tighten fastener to 40 ft. lbs. (54 Nm).

Install lower radiator hose.

Install both heater hoses.

Install cylinder head covers.

NOTE

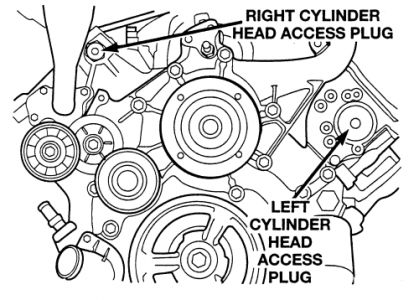

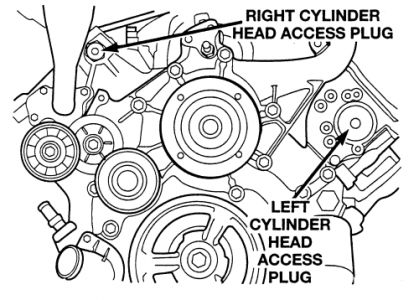

Before installing threaded plug in right cylinder head, the plug must be coated with sealant to prevent leaks.

Coat the large threaded access plug with Mopar � Thread Sealant with Teflon, then install into the right cylinder head and tighten to 60 ft. lbs. (81 Nm).

Install the oil fill housing.

Install access plug in left cylinder head.

Install power steering pump.

Install radiator fan.

Fill cooling system.

Connect negative cable to battery.

Compress and lock the primary chain tensioner"”4.7L engine

Secondary timing chain tensioner preparation"”4.7L engine

Timing chain system and alignment marks"”4.7L engine

Camshaft positioning"”4.7L engine

Use the Timing Chain Locking tool to lock the timing chains on the idler gear"”4.7L engine

Timing chain cover bolt torque sequence"”4.7L engine

Crankshaft timing marks"”4.7L engine

Cylinder head access plug locations"”4.7L engine

I hope this helps

Monday, April 29th, 2019 AT 6:56 PM

(Merged)