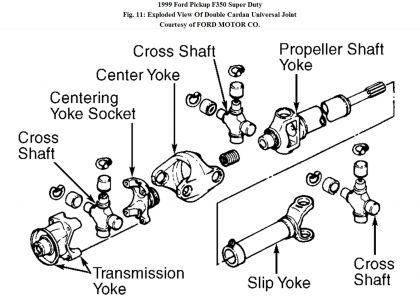

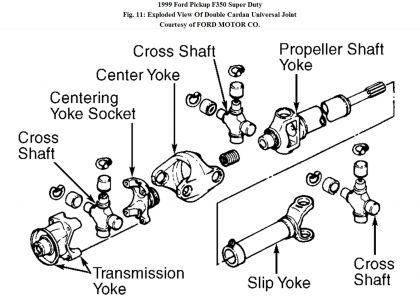

Did you index the driveshaft before you removed it? put it back in with your index marks? This sounds like you didn't...Removal & Disassembly 1. Raise and support vehicle. Mark drive shaft and differential companion flange or yoke for reassembly reference. Remove drive shaft from vehicle. Scribe alignment marks on yoke and shaft for reassembly reference. If joints are rusted or corroded, apply penetrating oil before pressing out bearing races or trunnion pin. Connect front and rear coupling shaft (if equipped). Attach universal joint to rear axle flange. Tighten nuts to specification. NOTE: Install drive shaft assembly so yoke ears at each end of shaft are on same plane.

4/29/2010 ...

SPONSORED LINKS

Thursday, April 29th, 2010 AT 2:07 PM