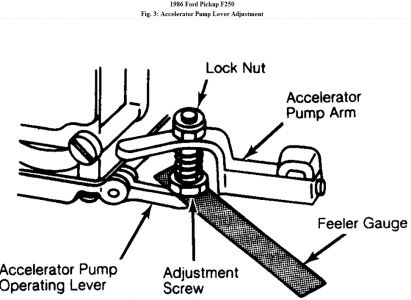

How did it run with the mechanical pump? If not good, your carb may need a new accelerator pump. This gives a shot of fuel for take off. Which carb is on it and I will see if I can locate a diagram.

Here are the specs and testing info for the fuel pump. Mechanical, you electric should be set to deliver this pressure.

FUEL PUMP

NOTE: 5.0L MPFI models use electric fuel pumps and 5.8L 4-Bbl. Models use

mechanical fuel pumps. On 7.5L 4-Bbl. Models, the Hot Fuel Handling

application uses in-tank mounted electric fuel pumps. All other

applications use mechanical fuel pumps.

Mechanical Fuel Pump (Volume Test)

On 5.8L and 7.5L 4-Bbl. Models, remove air cleaner. Slowly disconnect fuel line at filter. Using

a suitable container (one pint minimum), place at end of disconnected fuel line. With high

tension wire disconnected from coil, crank engine 10 seconds. If fuel flow is within

specification, proceed to pressure test. If not, proceed to next step.

1.

If fuel flow is low, repeat test using remote vented can of gasoline. Remove fuel pump inlet

hose. Connect a length of fuel line hose to fuel pump inlet and insert other end into remote can

of gasoline. If fuel flow is within specification, problem is plugged intake fuel filter or a kinked,

leaking or plugged fuel line or hose.

2.

Mechanical Fuel Pump (Pressure Test)

Remove air cleaner. Connect suitable pressure tester to end of fuel line. Start engine and let run for at

least thirty seconds. Read pressure and if not within specification, replace fuel pump. Reinstall air

cleaner.

Electric Fuel Pump

On 5.0L MPFI models, disconnect fuel return line at fuel rail. Connect hose to container. Connect

pressure gauge at diagnostic valve on fuel rail. Disconnect wiring connector at fuel tank and apply 12

volts to pump with jumper wire.

On 7.5L 4-Bbl. Models, disconnect fuel line just before the vapor separator unit. Connect a hose from

fuel line to a suitable container. If fuel flow is not within specification, electrically check fuel pump.

If still not within specification, replace pump-sender assembly.

FUEL PUMP SPECIFICATIONS

Application Specification

Electric Fuel Pumps

5.0L MPFI

Pressure (1) 39 psi (2.7 kg/cm2 )

Volume (1) 1 pint (.5L) in 30 seconds

7.5L 4-Bbl.

Pressure (1) 4.3 psi (.30 kg/cm2 )

Volume (1) 1 pint (.5L) in 20 seconds

Mechanical Fuel Pumps

Pressure 6.0-8.0 psi (.42-.56 kg/cm2 )

TUNE-UP - V8 -1986 Ford Pickup F250 Page 1 of 2

4/28/2010

Application Specification

Volume 1 pint (.5L) in 20 seconds

(1) Delivery capability averages.

TUNE-UP - V8 -1986 Ford Pickup F250 Page 2 of 2

4/28/2010

Tuesday, March 24th, 2020 AT 2:55 PM

(Merged)