Don't suspect PCM 1st

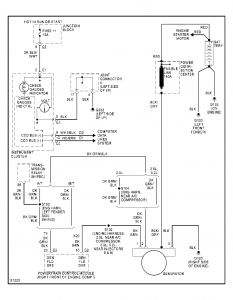

wiring issue most likely check connector at the PCM plug

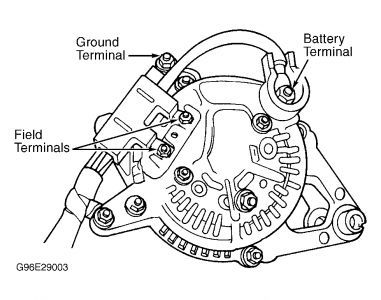

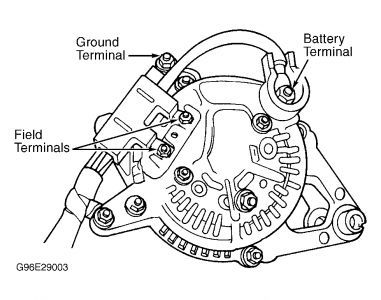

Using an external voltmeter, connect one voltmeter lead to B+ (battery) terminal on rear of generator. Connect other voltmeter lead to positive battery terminal. Go to next step.

Start engine and note voltage reading on voltmeter. If voltage is more than 0.4 volt, repair B+ circuit between battery and generator for high resistance If voltage is 0.4 volt or less, go to next step.

Turn ignition off. Using external voltmeter, connect one voltmeter lead to generator case. Connect other voltmeter lead to negative battery terminal. Go to next step.

Start engine and allow to reach operating temperature. Note voltage reading on voltmeter. If voltage is more than 0.1 volt, repair generator ground circuit between battery and generator for high resistance If voltage is 0.1 volt or less, go to next step.

Maintain engine speed at 1600 RPM. Using scan tool, read target charging voltage and charging voltage. Compare readings. If difference between readings is more than one volt, repair or replace generator as necessary . If difference between readings is one volt or less, go to next step.

Allow engine to idle. Turn ignition off. Perform TEST CH-1A - CHARGING SYSTEM NO CODE TEST.

TEST CH-1A - CHARGING SYSTEM NO CODE TEST

NOTE:Perform DTC TEST , Ensure battery is fully charged before proceeding.

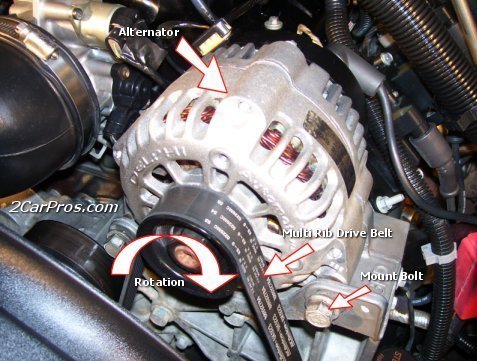

Inspect generator belt for proper tension and good condition. If generator belt is okay, go to next step. If generator belt tension is incorrect or belt is damaged, repair as necessary.

Start engine. Using scan tool, set engine speed at 2000 RPM for 30 seconds. Using scan tool, return engine speed to idle and read Diagnostic Trouble Codes (DTCs). If any DTCs pertaining to charging system exist, go to appropriate test. .

Turn ignition off. Turn ignition on with engine off. Using scan tool, actuate generator field. Using scan tool in voltmeter mode, backprobe Dark Green wire at 2-wire connector on rear of generator. Voltage should cycle from zero volts to battery voltage every 1.4 seconds.

While monitoring voltage display on scan tool, wiggle wiring from 2-pin connector on rear of generator to Powertrain Control Module (PCM). PCM is located between driver's side front fender and power distribution center, near battery.

If no interruption of normal voltage cycle exists when wiggling wiring, go to next step. If interruption of normal voltage cycle exists when wiggling wiring, repair wiring as necessary.

Using scan tool, read DTCs. If any DTCs exist pertaining to charging system, go to appropriate test.

Using external voltmeter, connect voltmeter positive lead on B+ (battery) terminal on rear of generator. Connect voltmeter negative lead to positive battery terminal.

Start engine and note voltage reading on voltmeter. If voltage is 0.4 volt or less, go to next step. If voltage is more than 0.4 volt, repair B+ circuit between battery and generator for high resistance.

Turn ignition off. Using external voltmeter, connect voltmeter positive lead on generator case. Connect voltmeter negative lead to negative battery terminal.

Start engine and note voltage reading on voltmeter. If voltage is 0.1 volt or less, go to next step. If voltage is more than 0.1 volt, repair generator ground circuit from generator case to negative battery terminal for high resistance.

Remove external voltmeter. Using scan tool, read and record battery voltage reading. Using external voltmeter, read and record battery voltage between positive and negative battery terminals.

Compare both voltage readings obtained in step 11). If difference between both voltage readings is less than one volt, test is complete. If difference between both voltage readings is one volt or more, go to next step.

Turn ignition off. Disconnect PCM connectors. Using external voltmeter, check voltage between ground and terminal No. 22 (Red/Black wire) at PCM Black connector. Compare voltage reading to voltage reading obtained using scan tool in step 11).

If voltage reading is not within one volt of voltage reading obtained using scan tool in step 11), replace PCM

If voltage reading is within one volt of voltage reading obtained using scan tool in step 11), repair high resistance on Red/White wire between PCM Black connector terminal No. 22 and battery.

SPONSORED LINKS

Tuesday, June 29th, 2010 AT 10:34 PM