Yes, if the control arm isn't damaged, just replace the bushings. That is what most do. Here are directions that I found. I hope they help,

1.Raise and safely support the vehicle on jackstands.

2.Remove the shock absorber.

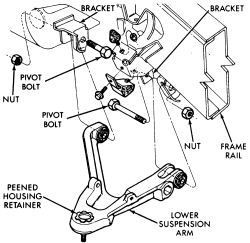

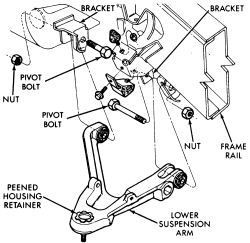

Fig. Fig. 1: Exploded view of the lower control arm mounting-Dakota models

3.Disconnect the sway bar from the lower control arm, if equipped.

4.Install spring compressor tool DD-1278, or equivalent to the coil spring and tighten the nut finger-tight, then back off half a turn.

5.Remove the cotter pin and lower ball joint nut.

6.Release the lower ball joint taper using ball stud loosening tool C-3564-A, or equivalent.

7.Remove the tool and remove the ball stud from the control arm. Release the compressor tool from the coil spring.

8.Pull the arm down and remove the spring with the rubber isolation pad from the vehicle. Remove the lower control arm pivot bolts from the crossmember and remove the arm from the vehicle.

To install:

9.Install the arm to the crossmember finger-tight. Install the spring with the rubber isolators. Install the compressor tool and compress it enough so the lower ball joint can be inserted through the knuckle.

10.Tighten the lower ball joint nut to 135 ft. lbs. (183 Nm). Install a new cotter pin. Remove the spring compressor.

11.Connect the sway bar from the lower control arm, if equipped.

12.Install the shock absorber.

13.Lower the vehicle completely. When the weight of the vehicle is off of the lifting apparatus, tighten the front lower arm pivot bolt to 130 ft. lbs. (176 Nm) and the rear nut to 80 ft. lbs. (108 Nm).

14.Have the alignment checked.

Let me know if this helps or if you have other questions.

Joe

SPONSORED LINKS

Sunday, August 15th, 2010 AT 10:48 PM