I found this somewhat interesting, as I have just bought from a friend a 1985 Chevrolet S10 pickup with a 2.5L engine. My friend, replaced all the sensors, distributor, he even bought a new exhaust manifold, and gave me the receipts, for the truck.

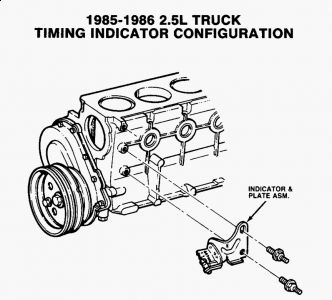

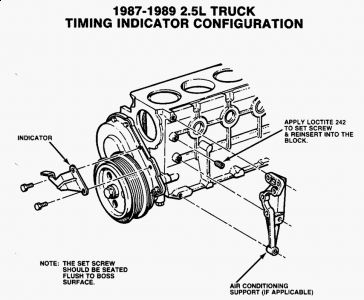

I replaced, the new exhaust manifold, intake manifold gasket, oil change (oil looked and ran like molasses), new oil filter, new valve cover gasket, new plugs, new antifreeze. Got everything together, fired it up, ran 20 minutes, then died. Timing was way off, timing was on the far side of the engine, on the passenger side.I felt bad. Called my dad, he sent a mechanic over, mechanic tells me, this is what we are going to do, we need to pull the distributor, remove half the radiator shroud, remove the fan blade,

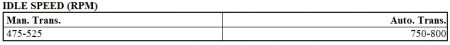

so you can get to crankshaft pulley bolt, your going to get a socket for the bolt, 1/2 sq drive breaker bar, remove the valve cover, so you can watch the rocker arms, going up and down, because the engine has to be reset to Top Dead Center. Before the distributor can be placed back into engine. Once everything else is done. And the engine is reset, then the distributor is put back in, the valve cover is put on, and the fan blade is on, and the shroud is on, then the engine, should start, and the timing can be set.

My Dad's mechanic, (thanks Dad!), Said this should have been done, when the original owner replaced the distributor, but he didn't. And how in the world did you ever get it started?

Beats me. But, I soon learned from his mechanic, anytime, you replace the exhaust manifold, or intake manifold or throttle body gasket, this has to be done, the 2.5L engine is very temperamental, and, the engine need s to be reset to Top Dead Center, and the distributor reinstalled. My Dads mechanic also gave me a Haynes manual for my truck, covering 1982-1990 Chevrolet S10/ Gmc 15 and blazer and jimmy trucks, a supplemental section covers the 2.5L engines.

SPONSORED LINKS

Sunday, July 17th, 2016 AT 7:07 PM