Check the TPS and the IAC TPS= throttl position sensor, and IAC= Idle air control.

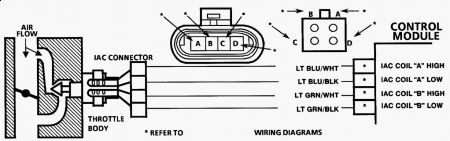

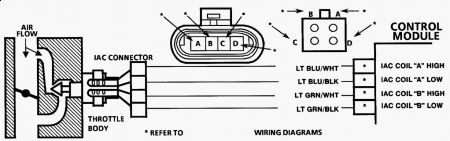

Idle Air Control (IAC) Valve 1. Disconnect harness connector to motor. Check resistance across IAC coil terminals "A" to "B" and "C" to "D". See Fig. 2 . Resistance should be 40-80 ohms. If okay, go to next step. If resistance is not as specified, replace IAC valve. 2. Check resistance between IAC terminals "B" to "C" and "A" to "D". Resistance should be infinite. If resistance is not as specified, replace IAC valve. NOTE: Functional testing of Idle Air Control (IAC) valve requires a bidirectional scan tool capable of cycling PCM/VCM output devices or a special IAC Driver and Noid Light Set (222L or J-37027). Text in TESTS W/CODES - 4.3L article may refer to Tech 1 tester, General Motor's bidirectional scan tool.

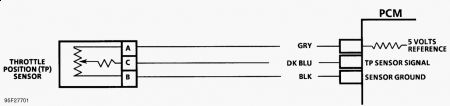

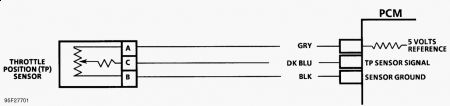

THROTTLE POSITION (TP) SENSOR 1. Install jumper wires to enable connection of a DVOM in parallel between TP sensor harness connectors. Connect DVOM positive lead to Dark Blue wire terminal. Connect negative lead to Black wire terminal. See Fig. 1 . 2. Turn ignition on, engine off. Slowly depress accelerator pedal. Signal voltage should gradually change from less than one volt at closed throttle to about 5.0 volts at wide open throttle position. If reading is not as specified, replace TP sensor. 3. TP sensor circuit malfunction should set a related trouble code. For further information, see the TESTS W/CODES - 4.3L article. Also see TP SENSOR ADJUSTMENT in the ADJUSTMENTS - 4.3L article.

Needle should sweep smoothly, no jerking...

SPONSORED LINKS

Wednesday, November 18th, 2009 AT 1:36 PM