Battery has been replaced and contacts cleaned.

Commutator interrupter switch has been replaced (part of ignition switch, not a easy job to replace).

Security light is working correctly, security key okay.

Dash lights, radio, A/C – heat fan, head lights, etc, work correctly.

Starter has been checked by local auto parts store a few times.

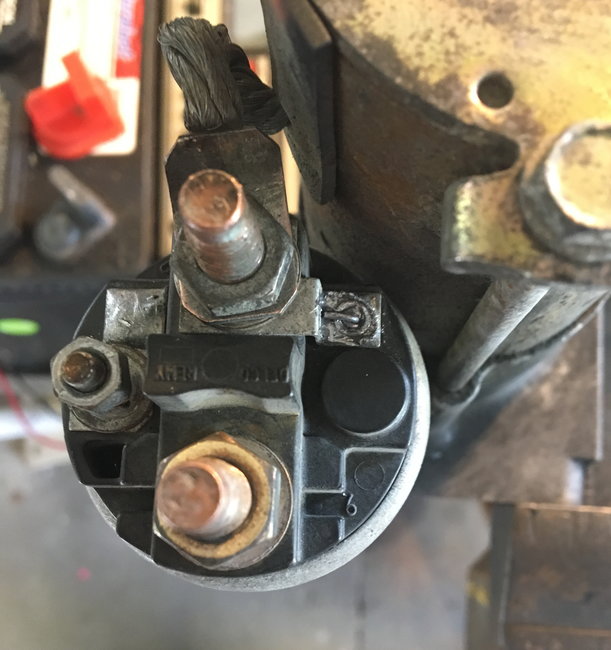

Getting twelve plus volts to starter solenoid.

Connected a Mallory Sonalert to the twelve plus volt starter solenoid wire so that you can hear when car will not crank. So I know I am getting the voltage to the solenoid.

SPONSORED LINKS

Tuesday, August 8th, 2017 AT 3:05 PM