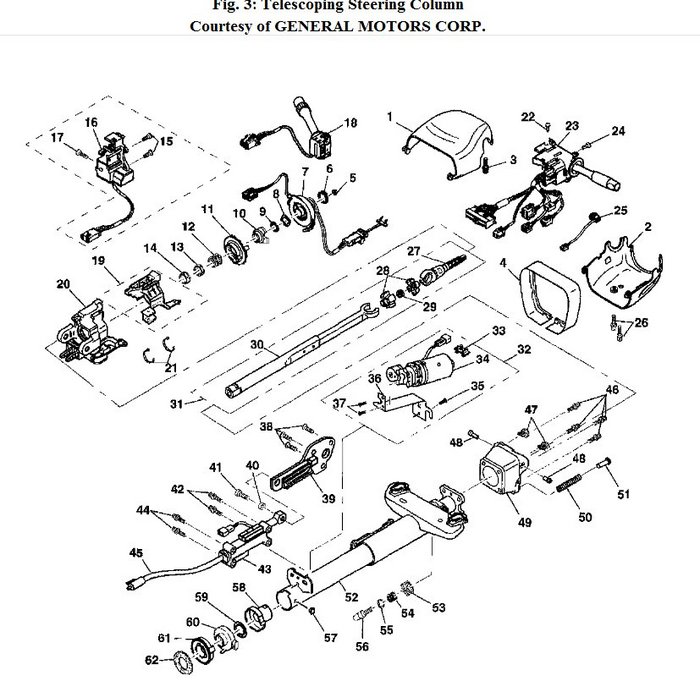

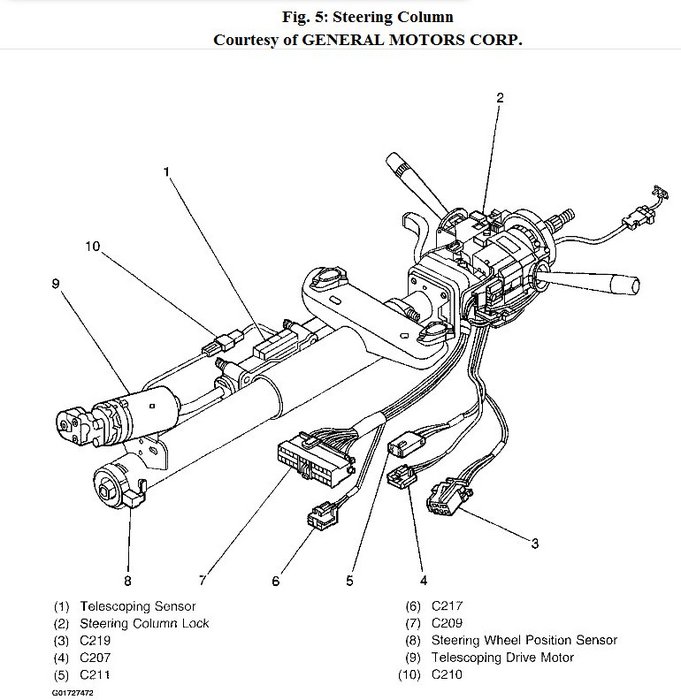

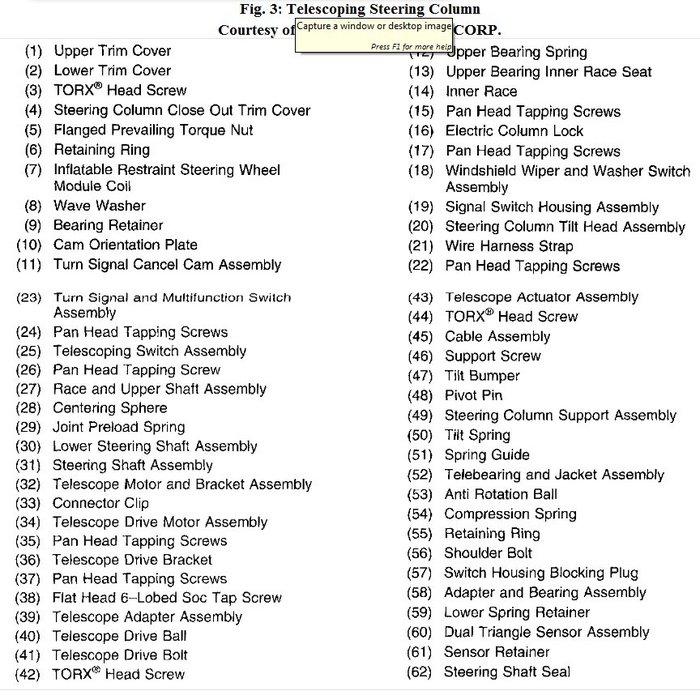

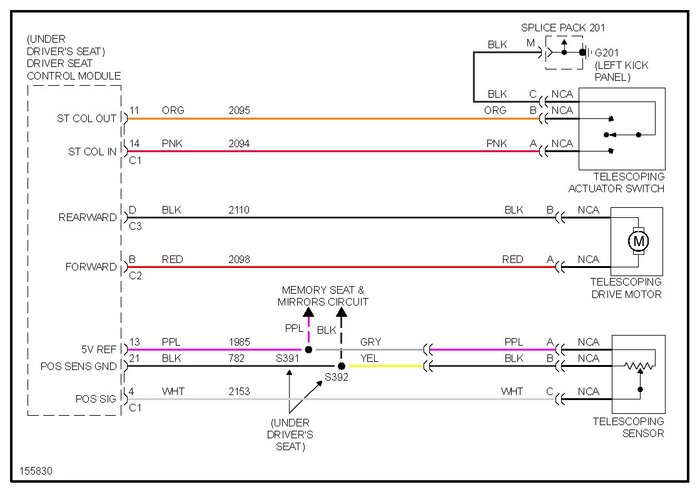

I am providing you with the schematic for the steering column with the telescoping components shown. There is a disassemled schematic, (which I had to break into 2 parts FIG3 diagram is 1 and the numerical description is 2), and an assembled view. You can correlate how it goes together by looking at the 2 views. I also gave you the wiring diagram for the telescoping circuit.

The first thing to do is check the fuse to make sure it is good. Then verify that the telescoping motor is getting 12 volts when the switch is actuated or the memory function to move it into place is activated. You may be able to hear it moving. If there is not 12 volts available to the motor, if it has 12 volts then the motor needs to be replaced. Then look at the wiring diagram so you can look for shorts and check grounds for a tight and corrosion free fit. If everything seems okay electrically, then take a look at the schematics and see if a part is loose such as an electrical connector or a bracket or the motor.

If everything is tight and all connectors are connected and there are no shorts and grounds are good. The mechanical can be ruled out as far as everything is tight and connected. Also, the basic function of the elctrical system is okay as far as the fuse, and there are no shorts and the grounds are not an issue. From there you will need to test the different modules of the elctrical system and test electronic components for proper voltage and/or resistance levels.

Let me know how it goes. Hopefully you won't have to go further as testing the electronics is a tough diagnostic. Just let me know if you need to performa it and want to do it and I will give you direction as much as possible to do so. However you will be limited in that some stuff will be circuit board level testing and requires special electronic test fixtures for specific panels or pinouts for the panels which are not provided in the manual that I have. I will give you as much as I can but it will have a limit as to what you can test without very specialized testing tools.

Images (Click to make bigger)

Wednesday, December 14th, 2011 AT 12:31 AM