Check the following and let me know what you find. After recording the codes, disconnect the battery negative terminal for a few minutes and reconnect. Remember to connect the MAF. Start engine and after engine stalled, recheck for trouble codes.

FUEL INJECTION & IGNITION SYSTEMS

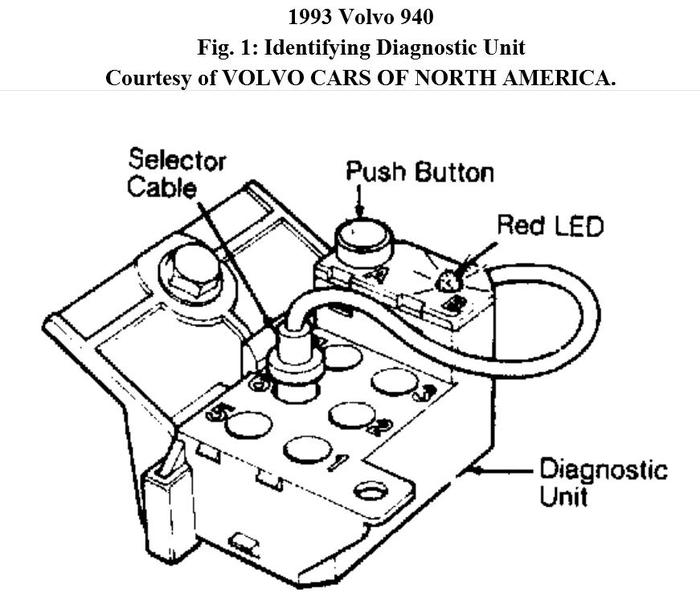

Fuel injection and ignition systems each feature a self-diagnostic function for fault tracing. A common diagnostic unit for retrieving codes is located in engine compartment, behind left strut assembly. Diagnostic unit is equipped with an LED indicator, activation button and function selector cable. See Fig. 1.

Diagnostic unit output socket No. 2 is used for fuel injection. Socket No. 6 is used for ignition system. Once selector cable has been inserted in correct slot, depressing button once, twice or 3 times selects from one of 3 control (fault tracing) functions.

Faults stored in ECU memory are read by observing LED flashes.

Diagnostic system for fuel injection ECU stores 17 fault codes and ignition ECU stores 9 fault codes. All fault codes contain 3 digits (example: 4-1-3). Since all codes have 3 digits, each code requires 3 series of flashes. A 3-second interval separates each series of flashes.

ENTERING SELF-DIAGNOSTICS

System monitors operation of components and switches. When component or switch is operated according to a set procedure, LED will display a 3-digit code. Failure to display a code indicates control unit has failed to detect operation of component/switch. In this case, fault lies with component/switch or associated connectors and wiring.

Functional check system can also test whether components/switches are correctly wired. For example, it can check whether permanent/magnet generator (engine speed sensor) and wiring are intact if engine fails to start.

Control Function No. 1

(Retrieving Codes)

This function displays any of 17 different fuel system codes stored in ECU memory during engine operation.

Control Function No. 2 (Activating Circuit Breakers)

This function tests fuel system circuit breakers. As it is activated, information is provided through LED in a flash code. This control function is generally used as a double-check after repairs.

Control Function No. 3 (Testing Fuel System Components)

This function tests fuel system components with engine stopped. It consists of a function cycle where diagnostic system activates components. Determine whether component is working by listening or putting a hand on it when it is activated.

Image (Click to make bigger)

Thursday, January 24th, 2013 AT 2:51 PM