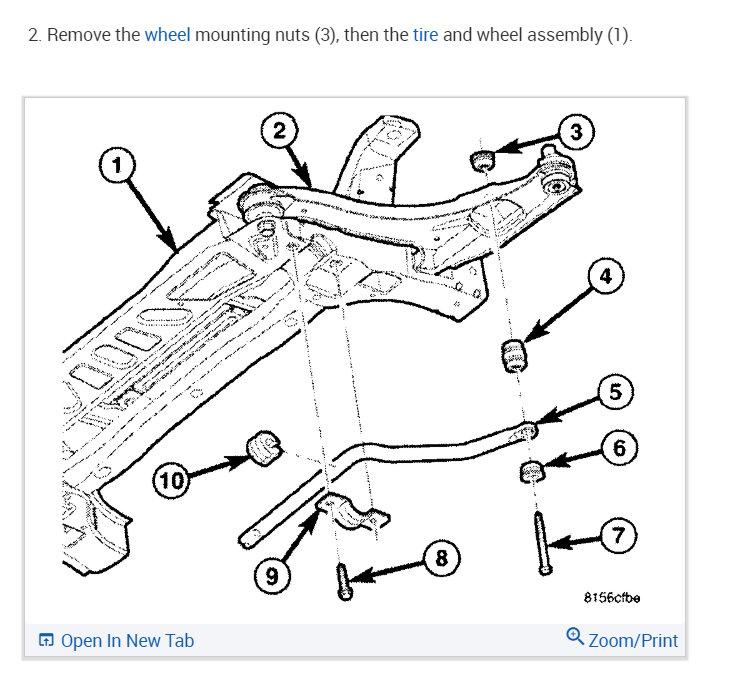

The bolt goes into a separate nut that is hold from spinning by a metal strap welded to it. By forcing the bolt, that strap broke loose and either it will bend and spin or the metal tab will break off the nut. There is an opening in the cross member where you can spray a lubricant in onto the bolt threads. You might also be able to reach the flame from an acetylene torch in there to warm the nut and expand it. If the tab is bent and wants to spin, you might be able to bend it back and hold it with a vise grip pliers. Chrysler has three lubricants that might help. When the bolt is rusted tight, their Rust Penetrant will free up things in 20 minutes that would take WD-40 all weekend. It's even better than PB Blaster, but you must wash it off later. If you don't, it opens the way for moisture to sneak in and will make the parts rust worse than before. When the bolt is already turning in the nut, Spray White Lube keeps the threads free so the bolt can be removed. A liquid soaks into the threads and takes the grease with it. When the liquid evaporates, it leaves the grease behind. MP-50 is a very light weight oil similar to WD-40 but it lubricates more than dissolves rust. Since your bolt is still hard to turn, the metal tab is still attached. If you can't get a torch flame on the nut, the best chance of getting the bolt loose is the Rust Penetrant. Spray it wherever you can get it on the threads, wait for a half hour, then try to run the bolt back in. Once you get it back in, spray it with the Spray White Lube, then remove it. If it doesn't come out by hand don't force it because you don't want to risk breaking the tab. You can also run the bolt in and out repeatedly to grind away the rust.

Saturday, May 2nd, 2020 AT 11:17 AM

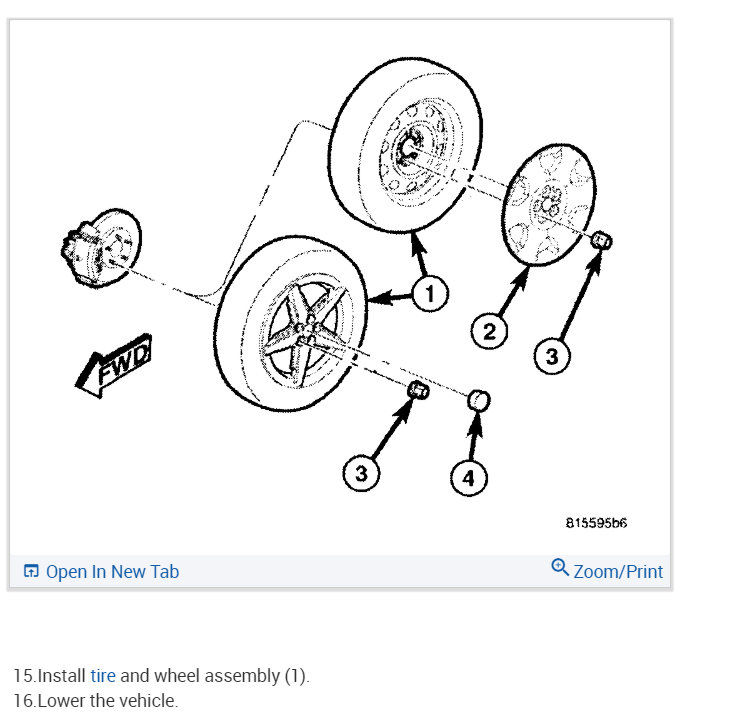

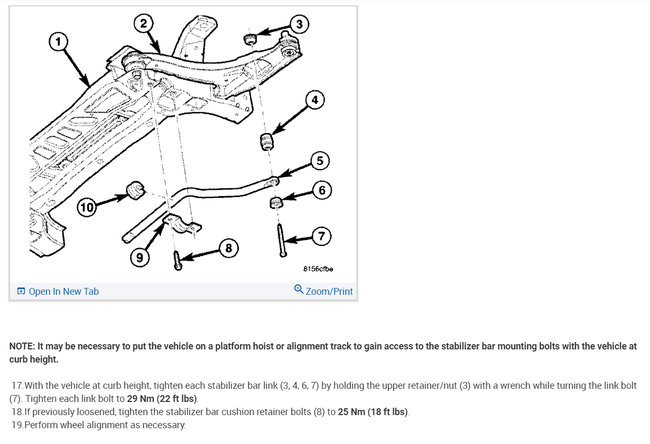

(Merged)