GOOD DEAL, WCA!!!

ARE YOU READY FOR YET ANOTHER TURDDOG NOVEL?

Glad you sent your Email.

LIKE MY WALMART PHOTO SHARING "JEEP MODIFICATIONS", I sent to it?

Did you see : YOU TUBE--BROADCAST YOURSELF--"TURD DOG FLIGHT"?

HE IS, I BELIEVE, AIRWORTHY AGAIN AFTER THE LAST "INCIDENT".

LET ME KNOW HOW THIS GOES---HERE OR BY OTHER MEANS.

PEAKING OUT YOUR BBD CARBURETOR (and others)

Before we start, it's been a long time since Mr. Jeep was running (he was locked in the closet, by his owner [Jeep Abuse!])

I want to verify our "Accelerator Pump" is still providing, A good squirt into both barrels!

ENGINE IS OFF! Look into Carb.

With a flashlight (NOT a "BIC" lighter!), Slowly pull your throttle back, you should see 2 "PERTTY" squirt gun streams of fuel, shoot, one into each barrel---Equal size, to each other!

This fuel AIDS in your engine, getting a burst of energy, to "GO", Every time you push the gas pedal, WITHOUT THIS, YOUR JEEP WILL HESITATE and maybe die, EVERY TIME YOU ACCELLERATE! (This could maybe be one reason, for a hesitation)If we do not get 2 even squirts, Carb may/should be repaired (rebuild) or replaced.

Ready to tune Mr. Carburetor

!st thing we are going to do is figure out where we are set now, just in case we have to come back to this point.

Go to the front of your Carb, there are 2 "Mixture" screws, they may be exposed, or they might be inside a little Tunnel.

When we move these screws, we are going to do it slow.

WHEN! we bottom out, we are going to GENTLY TOUCH BOTTOM (NO MORE THAN THAT)

If someone in the past has "Went Too Tight" our orifices may be "WOLLERED OUT" (one orifice may be larger than the other, air flow will be exponentially more than the other) and precise adjustment may not be achieved.

This is why we need to know our exact position NOW!. . .just so it will run (if we have to put it back)

IF adjusting correctly, ---"Just Ain't Happening"---(even if we cannot do this right, experimenting with your "Disaster", still may improve it a little!)

The next thing we need is a screwdriver; it must be LONG/SHORT ENOUGH to get to these screws, in your little "Obstacle Course" in front of the screws (stay away from the FAN!) It must fit the SCREW SLOTS WELL! (Slipping out, without knowing, means you lost your count!)

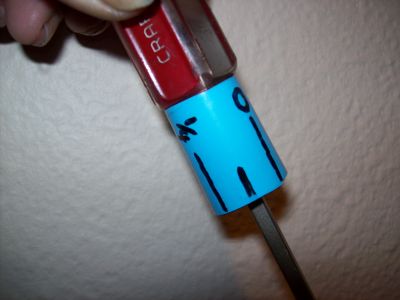

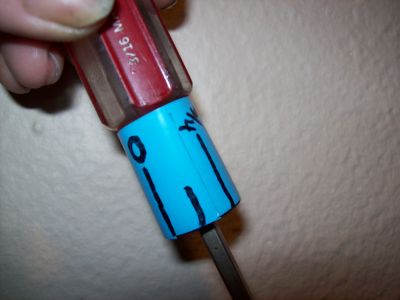

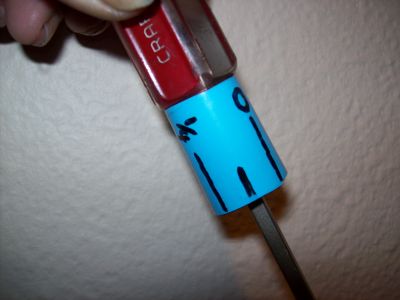

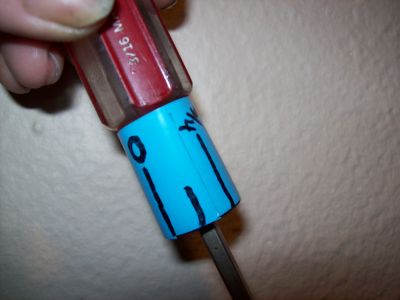

You may want to mark the Screwdriver handle with Tape ETC. so that you have 4 DIFFERENTLY MARKED increments (1/4 TURN MARKs for Reference! I PREFER 2, 180 degree marks line up with the screwdriver blade) we will be counting Turns, as you get better with this, you will graduate to 1/8 increments! You will be able to watch the flats of the screwdriver and have no need for marks!

I have whipped up a "Beginner Type" adjustment/counting screwdriver---with a piece of tape and a marker. MINE has 1/8 marks, But ONLY the � increments are labeled.

As you rotate MINE, COUNTERCLOCKWISE---it reveals "0", then � , then � , then � , then back to "0" (BACKING OUT ON A SCREW!)

MY "0" and � , CORROSPOND WITH THE THIN PARTS OF THE SCREWDRIVERS BLADE (NOT THE FLATS, really makes no difference)

I MUST REMEMBER, GOING THE OTHER WAY (CW), I MUST TRANSLATE THE INCREMENTS "BACKWARDS"!

YOU CAN MARK IT ANYWAY YOU WANT! ! ! (RED MARKER "IN"---BLACK MARKER "OUT"---(in this scenerio, My BLACK "1/4" would also be my RED 3/4, My BLACK 3/4 would also be my RED 1/4.

AS LONG AS YOU AND YOUR ASSISTANT UNDERSTAND.

DURING THIS WHOLE PROCESS"”YOU MAY WANT TO PERIODICALLY, REMOVE THE SCREWDRIVER AND VERIFY THE POSITIONS OF THE ACTUAL SCREW SLOTS IN THE CARBURETOR!

NUMBER 1 (#1)

We are going to call the screw closest to you NUMBER 1 SCREW the other will be NUMBER 2 SCREW, NUMBER 1 is the most important, because #2 is just going to be "ALONG FOR THE RIDE", during every adjustment.

NUMBER 2 (#2)

If there are plastic limiter caps over the mixture screws, find a home for both, in the woods behind your house!

To see where we are now, Install screwdriver in #1 watching your reference marks, turn it CLOCKWISE IN, till it touches bottom, EVER SO GENTLY!

Your Too Wide Screwdriver, scraping the sides, is not FOOLING YOU! [get one that fits easily into the "Tunnel"], You will be counting the turns, ACCURATLY down to the 1/8th (yours will vary DRASTICALLY, from mine!) . . .. . .. . .. . ...42-1/8 Turns----RECORD THIS NOW. . .before you forget!..............Then Do #2 . . .. . .. . .. . ...356-1/4 TurnsRECORD IT TOO!

We want the Jeep to somewhat run decently, in order to adjust the mixture screws----so let's start with #1 at 3-1/2 Turns BACKED OUT#2 is along for the ride, Bring him out 3-1/2 turns too! (He will follow from here on out)

CRANK UP VERIFY IT WILL RUN

If the Jeep----WILL NOT--- stay running Initially, Try both at 3 turns OUT or both at 4 turns OUT,we just want to maintain an idle, this SHOULD improve as we adjust! (you may sorta back out to whatever your #1 "originally was close to [going in], such as 3-1/4 turns, but put #2 at same setting as #1)

TURN OFF NOW, SO WE CAN CONTINUE, if we are good!

LET ME KNOW IF THINGS ARE ---NOT--- GOING WELL AT THIS POINT!

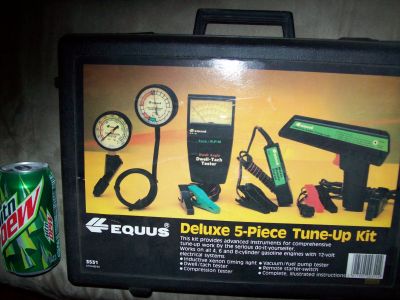

We have 2 ways to set the Carb, Vacuum Gauge or Dwell/Tach meter (Either way will work). For now we will use the DWELL/TACH METER. I like this method for several reasons: You can see "MICRO" movements of the needle, you can adjust Idle, up or down to RE-ZERO where you are at. . ..its a tool you already need!

Peak Vacuum should = Peak RPM

After you get good with the 6 cylinder scale, you can just watch the tip of the needle (more precise) on the "GENERIC" outer scale (on my meter, the voltmeter scale) to MAXIMIZE Precise, minute adjustments.

I have sorta rigged my meter so ONLY the 6 cylinder scale shows"”AND"”the top scale (voltmeter) shows. Basically: to find 700 RPM quickly, and maybe "Tweak off of 700 SLIGHTLY" to line up on a really CLOSE-BY voltmeter line [the up-most scale on my meter]. . ..(the most sensitive end of the needle)

Regardless which you use, insure you have plenty of light on the front of the carb. And your meter is lit well from behind you. I usually SQUINT ONE EYE (like firing a weapon) to LINE UP ON MY "ZERO MARK" to watch needle changes UP or DOWN. . .. . ...we are shooting for UP!

This NEWLY AQUIRED LINE will now become our "ZERO MARK", to see if our adjustment, INCREASES RPM or DECREASES RPM (if you feel more comfortable, stay on the 6 cylinder scale, you can just use 700 RPM, and remain lower on the needle)

Just to see if this "Tach Method" was as good as using the vacuum gauge, we had a Job Going at work, (I'm a plumber) that had this real expensive vacuum gauge going in. The gauge was very sensitive, and was about a foot in diameter, lots of increments (mine is about 3", minute changes are FAINT and Hard to detect).

I sorta borrowed it, for a day, before it was installed. We hooked it to my Jeep, along with the Dwell/Tach, I adjusted my Carb. And maxed out with my meter. . .. . .then came up with nearly the same settings, when we tried to "Tweak" it better using

the Monster Vacuum Gauge. . .. . ..I'm sold with the TACH method!

ACTUAL TUNING

Insure no other device is touching, or will EVER, hold our throttle open (remove or adjust it so that it will never affect the throttle). . ...the only 3 exceptions being: "Our Screw ,and the one beside it (choke fast idle). . ..and if you have A/C, any high idle solenoid that jacks up idle, to compensate for A/C compressor load.

Remove your air cleaner assembly.

Hook up your Dwell/Tach meter.

CRANK and warm engine to operating temperature.

Now check to see if the choke is fully open. . .. . .. . . CHECK: NOT "OUR SCREW", but the other one beside it, it is "OPEN SPACED" and NOT CONTACTING ANYTHING.

You SHOULD be back to NORMAL IDLE!YOUR METER IS SET TO TACHOMETER (RPMs)

Insure the throttle arm is closed (by spring) and you cannot physically make it close any more. . .. "OUR SCREW" should be contacting the stop. . ... When you are warm, verify we are idling at 700 RPM, Or MAKE IT HAPPEN (environmental changes could slightly affect this from last adjustment, and FOR SURE, our moving the mixture screws to the new starting point!)

Its decision time, we must pick our meter ZERO POINT.

On my meter, at this speed (700 RPM), I am really close to a mark on the upper scale [tip end, sensitive part of the needle), If your meter is like mine, the "4" mark (4 VOLTS) is ever so slightly DOWN, from this original idle mark.(700 RPM)

On the "6 Cyl. Scale", Moving RPM down slightly (to use the "Needle Tip" for "ZERO" on "4" ), would back you down from 700 RPM slightly (great! Manual says your Idle was 680 RPM anyway.) (We may still put it back, when we are done adjusting). We can NOW be on the TIP END of the needle and use "4" as our Zero Mark!

Every time you re-zero your IDLE SPEED, for now, Will be "4" on voltmeter scale. You already know, it is really slightly under 700 RPMs---no need to look at 6 cylinder scale while adjusting and re-zeroing with "Our Screw"

We are running, and at temp,

We may be "stumbling" a bit,

"4" on meter is ZERO for Idle speed (or "700"),

The carb will NO longer be referred to as: 3-1/2 turns---out; on both screws. . ...It is now ZERO! (Unless we get confused and must start over)

OUT IS "RICH". . .. . .. . .. . .. . ...IN IS "LEAN"

CALL THIS: "WHICH WAY DO I GO?"We are going to play with NUMBER 1 mixture screw, Insert your screwdriver and

SIMULTANEOUSLY! (TURN, WATCH METER, and WATCH SCREWDRIVER INCREMENTS!)

Give the screw � Turn Clockwise (slowly)

Did we improve on "4"?

NOW, RETURN TO ZERO with #1 (CCW � Turn)

Now turn it CCW � Turn [from zero]

Did "4" improve?

You must move slowly, allow engine several seconds (5-10) to fully react, when you adjust!

WHICH WAY MADE AN IMPROVEMENT?...... IN or OUT?

THIS NEXT, IS AN ASSUMPTION, and BASED ON RON'S JEEP----otherwise you should understand the process, going in!

WE (RON and I) HAD IMPROVEMENT BACKING #1 OUT, � Turn from "ZERO" [actually #1 is now 3-3/4 off the bottom], NOW WE HAVE SORTA ESTABLISHEDBACKING OUT---IMPROVES RPM! (Or opposite)

WHAT WE DO TO #1WE DO TO #2! BACK HIM OUT � TURN, TOO! ---RPM will probably improve with #2 (actually at 3-3/4 OUT, both screws)

OUR METER NEEDLE IS ABOVE THE "4" NOW [climbing] (improvement w/BOTH screws!)

RE-ZERO IDLE SPEED ["OUR SCREW"] TO "4" AGAIN (SO WE CAN DETECT IMPROVEMENT EASILY!)

We are going to say, EVERTHING IS BACK TO ZERO (forget 3-3/4. . .if you mess-up, you can always, rebottom the screws, counting the turns as you go. . ..set both screws the same, AND CALL THAT, YOUR NEW ZERO!)

NOTE: Most beginners get messed up trying to keep up with their turns.

Just remember----whatever you Finally "tweak" #1, reach over and do #2 the same increment.

Call it zero (each turn of #1, will be a fresh start!)

When we are COMPLETELY done. . ...we are going to count BOTH, down to the bottom and Verify they were the same, Then put them back where they belong. . .. . .. . .and record, in our manual, their FINAL, backed out setting!

CONTINUEING WITH ADJUSTMENT!

We are going to continue to back out, � at a time as before, REMEMBER TO DO #2 EACH TIME!

We are finally going to HIT and Probably---BACK OUT PAST---Our "SWEET SPOT" (Meaning: PEAKED OUT! NO CHANGE IN, NO CHANGE OUT)

When our "4" Zero, does not improve or goes downhill (decreases in RPMs) WE WILL STOP MAKING THESE, "COARSE", CCW, � Turn Adjustments!

We are TOO FAR OUT NOW (not by much, and we are TOO RICH!)

CALL THIS: "RE-TWEAKING"We are going to EASE back in Toward the "SWEET SPOT" (clockwise)[opposite what we were doing]----this time at 1/8 or 1/16 increments. . .. . .#2 will follow along. . ..each "Finished" process will be called ZERO, as before. . ... RE-ZERO OF THE METER [idle speed]

IT IS UP TO YOU, when we are this close to Finish, whether to keep moving idle down to 700 RPM (or back to "4"), WE JUST WANT TO DETECT SLIGHT IMPROVEMENTS NOW!

Watching the meter and FINE ADJUSTMENT amounts---IS REALLY CRITICAL AT THIS POINT!

When your RPM, MAXES OUT---you are sitting on the "SWEET SPOT"Stay there! (Both screws)

AT THIS POINT, YOU MAY WANT TO "MAKE SURE" ,as long as you keep #1 and #2" EVEN"----and BACKING-UP or GO FORWARD EVENLY. . ...as long as you approach the "Sweet Spot" from the "RICH" side [screw in to find it, NOT OUT], for the Final "Tweak"

PLAY ALL YOU WANT! (screws even at all zero points!, IN or OUT)Confused? Go back to a known start point!

This will really impress your friends later, when you "Show Out".

Re-zero "Our Screw" to "4" (last time) Throttle up a few times, insure, we "Settle back in" to our Zero "4" setting, when engine stabilizes.

SHUT HIM DOWN

Run #1 in count turns, record---Run #2 down record turns, was it same as #1 turns?----SHOULD BE!

BACK OUT BOTH SCREWS---to your LAST and ALMOST FINAL ZERO

Crank up, engine settles in, verify idle speed, "Tweak slightly", OUT then IN, both screws---INSURE "SWEET SPOT" IS STILL YOUR FRIEND! SAME SPOT!

DONE, AS FAR AS I AM CONCERNED, WITH THE "HOW TO" PART

IF YOU BEGAN THIS WHOLE PROCESS BY, SCREWING IN THE SCREWS FOR IMPROVEMENT, READ NOTE BELOW.

NOTE"”if you began this process in reverse (starting by screwing in, in the "WHICH WAY DO I GO?" PARAGRAPH) You will pass the "SWEET SPOT" and will wind up on its leaner side, WHEN RPM starts dropping.

AT THIS POINT! ---Back out � to � of a turn (both screws) and approach the "Sweet Spot" from the RICH SIDE ("SCREWING IN", Will eventually hit the "Sweet Spot") using small increments (AS WE DID, IN "RE-TWEAKING" PARAGRAPH)

Some people say you should "finish" by backing out, maybe a 1/8 turn [a tad rich, from sweet spot] (both screws) You can experiment all you want---I AM LEAVING THEM ALONE---I HAVE SEEN NO ADVANTAGE OF MOVING THEM [rich], DURING MY EXPERIMENTS!

ARE WE RUNNING SUPER NOW!Lets leave idle set at 700 RPM, just is sorta a good even speed![especially to help warm up]......If you get a lot of tailpipe "Rumbling" during DECELERATION (foot completely off of gas) you may want to drop idle slightly. I WOULD STAY ABOVE 650 RPM (won't cut off) and BELOW 750 RPM (STAY IN IDLE CIRCUIT, NOT ON PRIMARIES)!

LET ME KNOW HOW IT GOES, TELL ME YOUR/MY PROBLEM AREAS SO I CAN TRY TO GET IT/EDIT RIGHT, FOR THE NEXT POOR SOUL THAT MIGHT READ IT!

I HAVE ONE MORE THING YOU MAY WANT TO TRYIF YOU LET ME KNOW---HAVE PICS ON STAND-BY

SORT OF A FIELD, ON VEHICLE, CARBURATOR CLEAN-OUT, PROCEDURE! (May improve your "Sweet Spot")

We have disabled many things on your rig, Carb. Replacement recommendation is: A 1979 ERA BBD, like the one in my pic, somewhere above. (If, you really need it.). . ..I also like a manual choke. Let you pick when you need it, there are fewer in-between mechanicals. . .. . .. (insure your choke is functioning"”take off the breather and inspect whether it goes closed, when the throttle arm is actuated, WHEN IT IS NOT RUNNING---COLD"”LIKE ON A COOL MORNING!)

I WANT ALL OF THE DRAMA AND ANY "SCRATCHING OF THE HEAD EXPERIENCES""”CAUSED BY MY ANSWERS"”SO I CAN IMPROVE---NEXT GUY MIGHT UNDERSTAND THE SITUATION!

Correct terminology for stuff, I sorta made a name up for----Can be found in your manual!

Wash your engine (inexpensively and well) with "Purple Power" Let it sit for about 5 minutes, KEEP IT OFF OF EXTERIOR PAINT! Rinse with a hard stream of water. . .. (Rinse body well too) if you soak dist. cap (a lot) and trouble cranking up, Remove cap and dry it out.

Close your hood----ONLY OPEN IT NOW, FOR YOUR FRIENDS TO ADMIRE IT!

I told you that I would help you all the way!

Love Turddog

Friday, May 7th, 2010 AT 2:16 PM