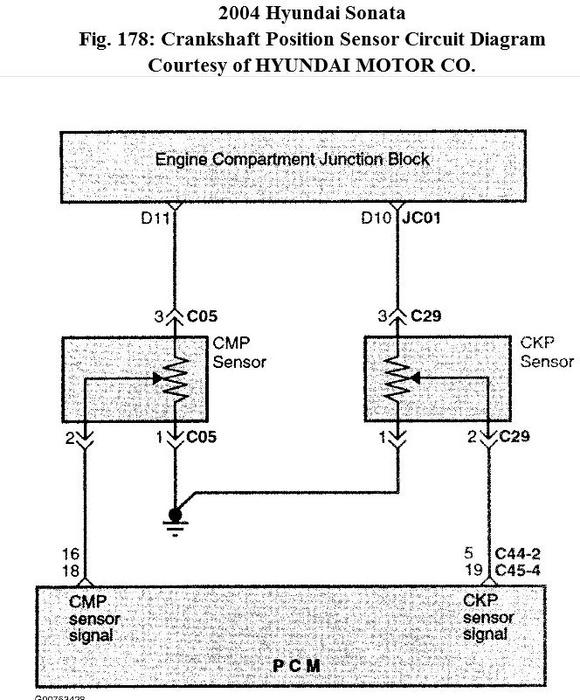

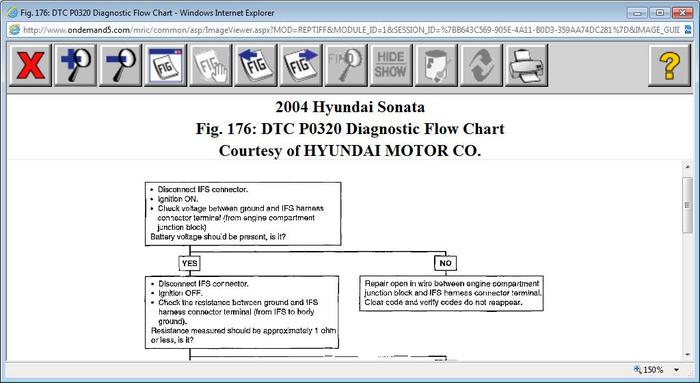

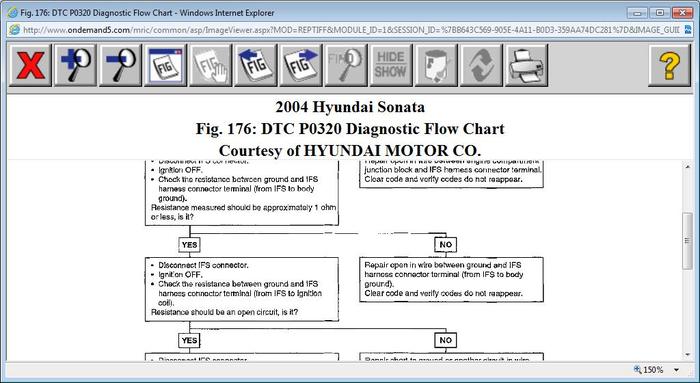

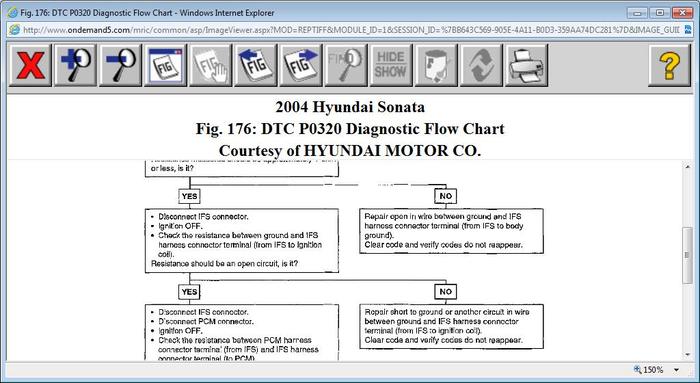

OK, Now "we" are getting somewhere! The pages you included allowed me to determine that there IS voltage to the sensor. In the process I DID figure out how to "test/read" the sensor while it is still on the vehicle. I'm tempted to say how I accomplished that (for a fee!) But that would be mean. All I had to do was take a wire from the positive battery terminal to the "top" pin on the plug (red wire). Then read the return voltage on the lower right pin (black wire). Both the old and new sensors read about 10+ volts returning. Come Monday we are going to tow it to a local shop and put it on their machine.

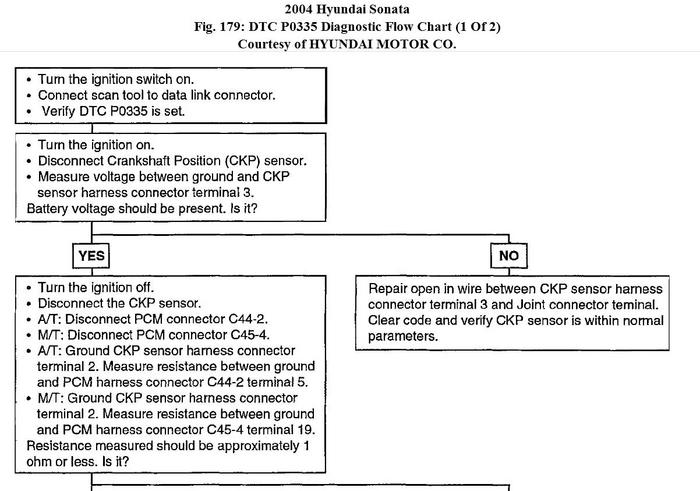

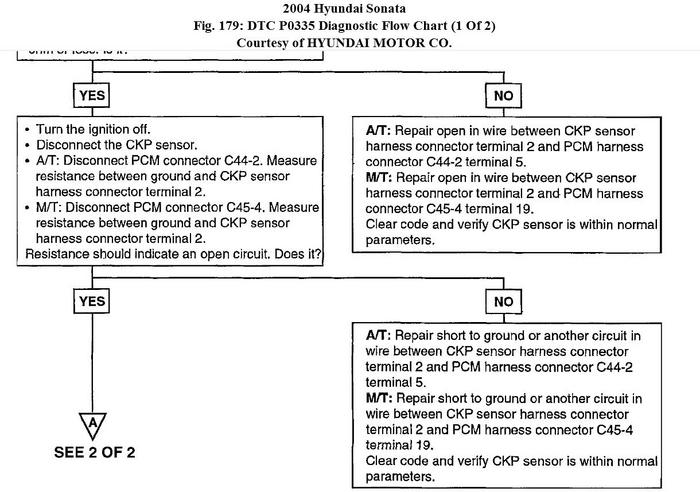

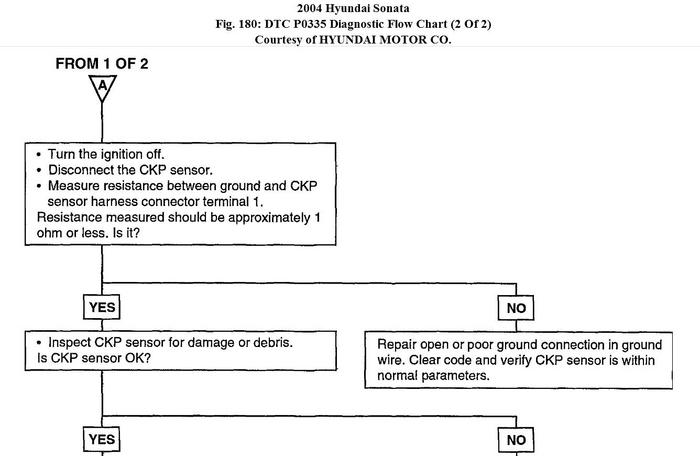

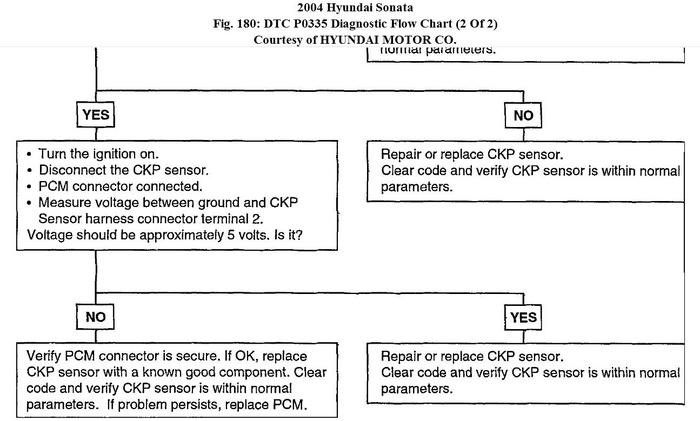

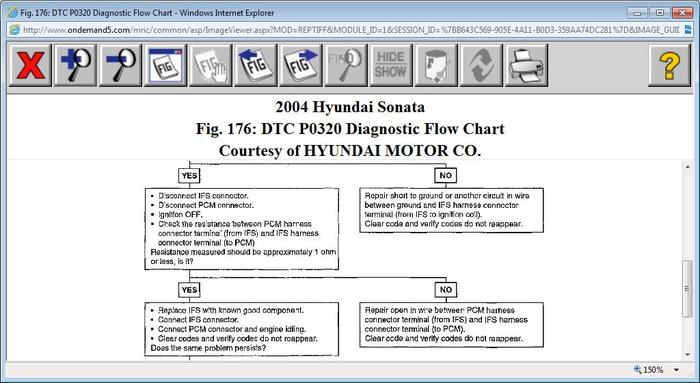

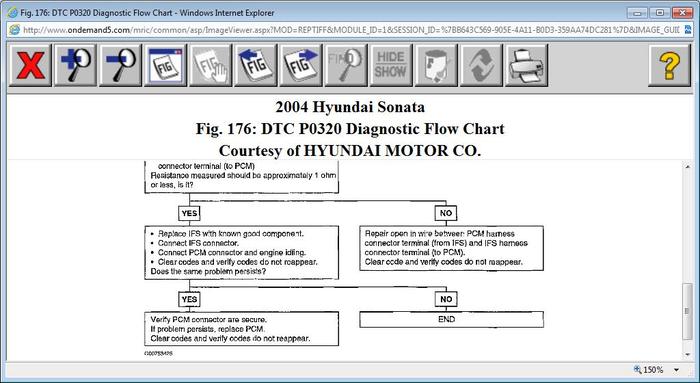

Figure 180 says to measure resistance between ground and CKP terminal #1. I read MORE than 1 ohm, 2. Something. Is that OK? Then it says to measure voltage between ground and CKP terminal #2. I got 4.68volts. Is that OK?

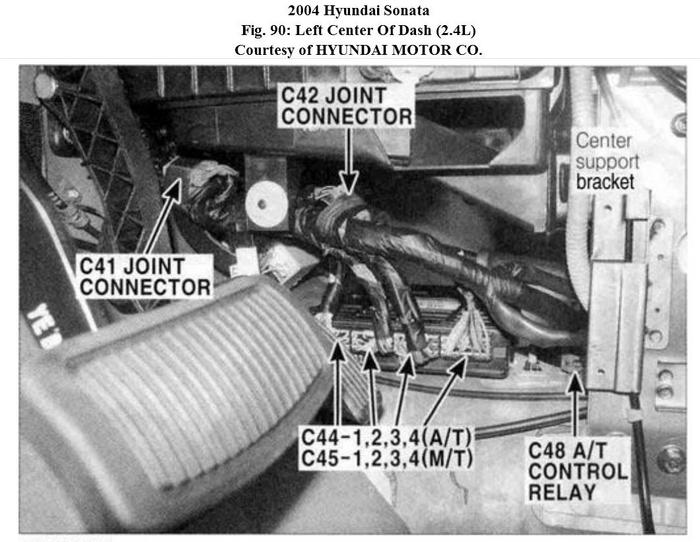

The only test I couldn't do was the "A/T:Disconnect PCM connector C44-2" as none of the paper work I have available to me told me WHERE that plug was.

I have learned a couple of things while working on this problem. 1) I will NOT work on another late model car without access to the Factory Shop Manual for that vehicle right from the start. 2)I will (most likely) NOT take the diagnosis from a Code reader as "fact".

Will check back later to see if anyone responds to the questions I just asked.

PS. I am NOT happy with the first 2 responses at all. The next 1 was not much help. The 4th one was at least some help. But for the money I got charged I am not at all happy. I was led to believe I wouldn't pay if I wasn't "totally satisfied" but I don't see a way to change that now. As a result I will not recommend this site. Sincerly, Mr. Wise

Saturday, January 14th, 2012 AT 4:12 PM