SPEEDOMETER/ODOMETER INACCURATE

Sedan & Wagon

Turn ignition off. Connect scan tool and retrieve Diagnostic Trouble Codes (DTC) following manufacturer's instructions. If no DTCs are present, go to next step. If DTCs are present, see appropriate SELF-DIAGNOSTICS article in ENGINE PERFORMANCE. Repair DTCs as necessary, then retest system.

Using scan tool, observe Vehicle Speed Sensor (VSS) output Parameter Identification (PID) while assistant drives vehicle over range of speeds on various road surfaces. If VSS PID varies smoothly with vehicle speed, go to next step. If VSS PID does not vary or is erratic, see appropriate SELF-DIAGNOSTICS article in ENGINE PERFORMANCE to diagnose VSS.

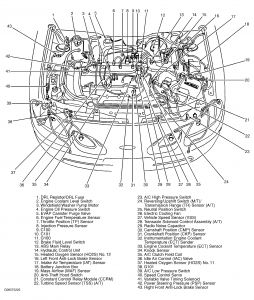

Remove and check OBDII 10-amp fuse in engine compartment fuse box. If fuse is okay, reinstall fuse and go to step 5. If fuse is blown, go to next step.

Turn ignition off. Remove instrument cluster. See INSTRUMENT CLUSTER under REMOVAL & INSTALLATION. Disconnect all instrument cluster electrical connectors. Measure resistance between ground and instrument cluster harness connector C252 terminal No. 12 (Green wire). See Fig. 6. Measured resistance should be more than 10 k/ohms. If resistance is more than 10 k/ohms, replace OBDII 10-amp fuse and go to next step. If resistance is less than 10 k/ohms, repair short to ground in Green wire between instrument cluster harness connector and fuse. See WIRING DIAGRAMS.

Turn ignition off. Remove instrument cluster. See INSTRUMENT CLUSTER under REMOVAL & INSTALLATION. Disconnect instrument cluster electrical connectors. Measure voltage between ground and instrument cluster harness connector C252 terminal No. 12 (Green wire). See Fig. 6. Voltage should be more than 10 volts. If voltage is more than 10 volts, go to next step. If voltage is less than 10 volts, repair short to voltage in Green wire between instrument cluster harness connector and fuse. See WIRING DIAGRAMS.

Turn ignition off. Disconnect Vehicle Speed Sensor (VSS) harness connector C132. Measure resistance of Blue wire between VSS harness connector and instrument cluster harness connector C252 terminal No. 7. See Fig. 6. Measure resistance of White/Black wire between VSS harness connector C132 and instrument cluster harness connector C253 terminal No. 9. Resistance in both tests should be less than 5 ohms. If resistances are as specified, go to next step. If resistances are not as specified, repair open in White/Black or Blue wire. See WIRING DIAGRAMS.

Measure resistance between ground and instrument cluster harness connector C253 terminal No. 9 (White/Black wire). Resistance should be more than 10 k/ohms. If measured resistance is more than 10 k/ohms, go to next step. If resistance is less than 10 k/ohms, repair short to ground in White/Black wire.

Turn ignition on. Measure voltage between ground and instrument cluster harness connector C252 terminals No. 8 and 4 (Black/Yellow wire). See Fig. 6. Voltage should be more than 10 volts. If voltage is more than 10 volts, go to next step. If voltage is less than 10 volts, repair short to voltage in Black/Yellow wire between instrument cluster connector and fuse. See WIRING DIAGRAMS.

Turn ignition off. Visually inspect instrument cluster printed circuit for damage, cracks or hot spots. If instrument cluster printed circuit is okay, replace speedometer. If instrument cluster printed circuit is damaged, replace printed circuit and gauge contact clips. See PRINTED CIRCUIT under REMOVAL & INSTALLATION.

TEST E: TACHOMETER INACCURATE

Sedan & Wagon

Using scan tool, observe RPM output Parameter Identification (PID) over range of engine speeds. If RPM PID varies smoothly with vehicle RPM, vehicle is okay. If RPM PID does not vary or is erratic, see appropriate SELF-DIAGNOSTICS article in ENGINE PERFORMANCE to diagnose Clean Tach Output (CTO) circuit. If only tachometer is inaccurate or inoperative, go to next step.

Turn ignition off. Remove instrument cluster. See INSTRUMENT CLUSTER under REMOVAL & INSTALLATION. Disconnect instrument cluster electrical connector C253. See Fig. 7 or Fig. 8. Turn ignition on. Measure voltage between ground and instrument cluster harness connector C253 terminal No. 8 (Black/Yellow wire). Voltage should be more than 10 volts. If voltage is more than 10 volts, go to next step. If voltage is less than 10 volts, repair short to voltage in Black/Yellow wire between instrument cluster connector and fuse. See WIRING DIAGRAMS.

Turn ignition off. Measure resistance between ground and instrument cluster harness connector C253 terminal No. 7 (Black/Green wire). See Fig. 7 or Fig. 8. Resistance should be less than 5 ohms. If resistance is less than 5 ohms, go to next step. If resistance is more than 5 ohms, repair open in Black/Green wire between instrument cluster connector and ground. See WIRING DIAGRAMS.

Visually inspect instrument cluster printed circuit for damage, cracks or hot spots. If instrument cluster printed circuit is okay, go to next step. If instrument cluster printed circuit is damaged, replace printed circuit and gauge contact clips. See PRINTED CIRCUIT under REMOVAL & INSTALLATION.

Install EEC-V 104-pin Breakout Box (014-00950) following manufacturer's instructions. Measure resistance between breakout box terminal No. 48 and instrument cluster harness connector C253 terminal No. 6 (Light Green/Red wire). See Fig. 7 or Fig. 8. Resistance should be less than 5 ohms. Measure resistance between ground and instrument cluster harness connector C253 terminal No. 6 (Light Green/Red wire). Resistance should be more than 10 k/ohms. If both resistances are as specified, see appropriate SELF-DIAGNOSTICS article in ENGINE PERFORMANCE to diagnose Clean Tach Output (CTO) circuit. If resistances are not as specified, repair open in Light Green/Red wire. See WIRING DIAGRAMS

SPONSORED LINKS

Thursday, January 15th, 2009 AT 7:53 PM