Hi memorex,

Thank you for the donation.

Here are some test that you can carry out to determine the cause.

TEST C: PASSENGER'S SIDE POWER WINDOW INOPERATIVE

1.If description and operation has been reviewed, go to next step.

2.Verify passenger's side power window is inoperative. If passenger's side power window is inoperative, go to next step.

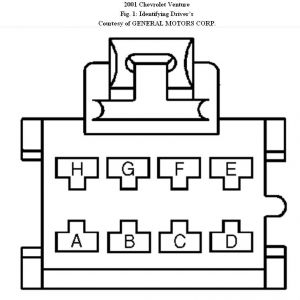

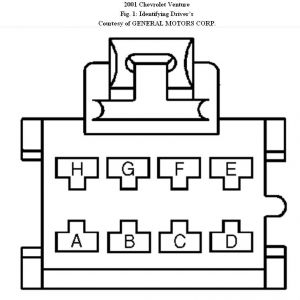

3.Disconnect passenger's side power window switch 8-pin harness connector. Turn ignition switch to RUN position. Using test light connected to ground, probe passenger's side power window switch harness connector terminal "F" (Yellow wire). See Fig. 1 . If test light illuminates, go to next step. If test light does not illuminate, go to step 13 .

4.Connect test light between passenger's side power window switch harness connector terminals "D" (Tan wire) and "H" (Light Blue wire). Using power window master switch, press passenger's side window switch to UP and DOWN positions. If test light illuminates in both positions, go to next step. If test light does not illuminate in either position, go to step 6 .

5.Connect passenger's side power window switch harness connector. Disconnect passenger's side power window motor 2-pin harness connector. Connect test light between passenger's side power window motor harness connector terminals "A" (Dark Blue wire ) and "B" (Brown wire). Press passenger's side power window switch to UP and DOWN positions. If test light does not illuminate either position, go to step 8 . If test light illuminates in both positions, go to step 10 .

6.Check for open in Light Blue wire between power window master switch and passenger's side power window switch. If problem does not exist, go to next step. If problem exists, repair as necessary. After repair, go to step 17 .

7.Check for open in Tan wire between power window master switch and passenger's side power window switch. If problem does not exist, go to step

11 . If problem exists, repair as necessary.

After repair, go to step 17 .

8.Check for open in Dark Blue wire between power window master switch and passenger's side power window switch. If problem does not exist, go to next step. If problem exists, repair as necessary. After repair, go to step 17 .

9.Check for open in Brown wire between power window master switch and passenger's side power window switch. If problem does not exist, go to step

12 . If problem exists, repair as necessary. After repair, go to step 17 .

10.Check passenger's side power window motor harness connector for poor connections or loose terminals. If problem does not exist, go to step

14 . If problem exists, repair as necessary. After

repair, go to step 17 .

11.Check power window master switch harness connector for poor connections or loose terminals. If problem does not exist, go to step 15 . If problem exists, repair as necessary. After repair, go to step 17 .

12.Check passenger's side power window switch harness connector for poor connections or loose terminals. If problem does not exist, go to step

16 . If problem exists, repair as necessary. After

repair, go to step 17 .

13.Repair open in Yellow wire between passenger's side power window switch and instrument panel fuse block. After repair, go to step 17 .

14.Replace passenger's side power window motor. After repair, go to step 17 .

15.Replace power window master switch. After repair, go to step 17 .

16.Replace passenger's side power window switch. After repair, go to next step.

17.Operate system to verify repair. If problem does not exist, system is okay. If problem exists, go to step 2 .

TEST C: FRONT WIPERS INOPERATIVE IN ONE OR MORE MODES

1.If description and operation has been reviewed, go to next step.

2.Turn ignition switch to RUN position. Turn multifunction switch through all switch positions. If front wipers do not operate normally in all modes, go to next step. If front wipers operate normally in all modes, diagnose intermittent condition.

3.Turn ignition switch to LOCK position. Disconnect multifunction switch 48-pin harness connector C201. Harness connector C201 is located to left side of steering column, near base. Disconnect front wiper motor 6-pin harness connector. Check for open, high resistance or short to ground in Purple wire between front wiper motor and multifunction switch. If problem does not exist, go to next step. If problem exists, repair as necessary. After repair, go to step

13 .

4.Check for open, high resistance or short to ground in Gray wire between front wiper motor and multifunction switch. If problem does not exist, go to next step. If problem exists, repair as necessary. After repair, go to step 13 .

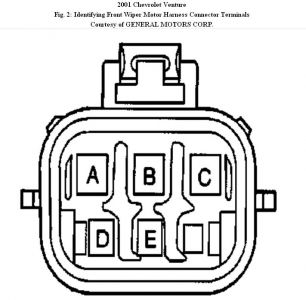

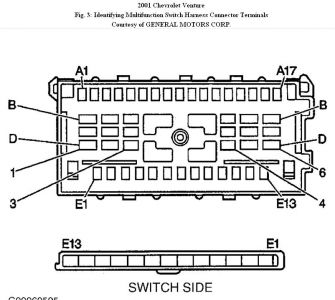

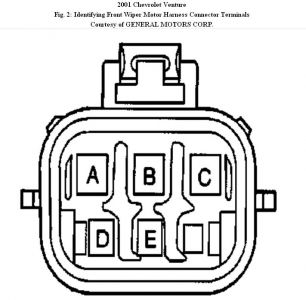

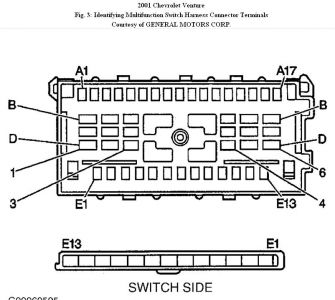

5.Check for open, high resistance or short to ground in Dark Green wire between front wiper motor and multifunction switch. See Fig. 2 and Fig. 3. If problem does not exist, go to next step. If problem exists, repair as necessary. After repair, go to step

13 .

6.Measure resistance between multifunction switch pigtail harness connector C201 terminals E3 (Dark Green wire) and E9 (Yellow wire) - (component side). See Fig. 3 . Turn wiper portion of multifunction switch to MIST, LO and HI positions. If resistance is less than 2 ohms, go to next step. If resistance is 2 ohms or more, go to step 10 .

7.Measure resistance between multifunction switch pigtail harness connector C201 terminals E3 (Dark Green wire) and E9 (Yellow wire) - (component side). Turn multifunction switch through all DELAY positions. Resistance should be 39-680 k/ohms. If resistance is as specified, go to next step. If resistance is not as specified, go to step 10 .

8.Measure resistance between multifunction switch pigtail harness connector C201 terminals E3 (Dark Green wire) and E9 (Yellow wire) - (component side). Turn wiper portion of multifunction switch to MIST, LO and HI positions. Resistance should be 24 k/ohms. If resistance is as specified, go to next step. If resistance is not as specified, go to step 10 .

9.Connect multifunction switch harness connector C201. Connect front wiper/washer motor harness connector. Turn ignition switch to RUN position. Turn wiper portion of multifunction switch to HI position. If front wipers operate normally, go to step

11 . If front wipers do not operate normally, go to step 12 .

10.Replace multifunction switch. After repair, go to step 13 .

11.Replace front wiper drive system module. After

repair, go to step 13 .

12.Replace front wiper motor. After repair, go to next step.

13.Operate system to verify repair. If problem does not exist, system is okay. If problem still exists, go to step 3 .

As to the A/C not cold, get the low and high pressure readings and let me know what they are. Did you check if the compressor is engaging?

SPONSORED LINKS

Thursday, July 29th, 2010 AT 8:24 AM