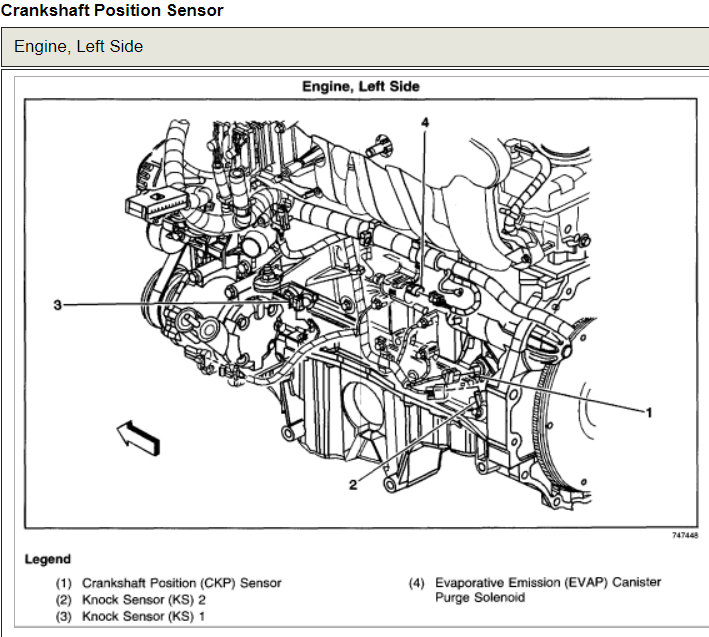

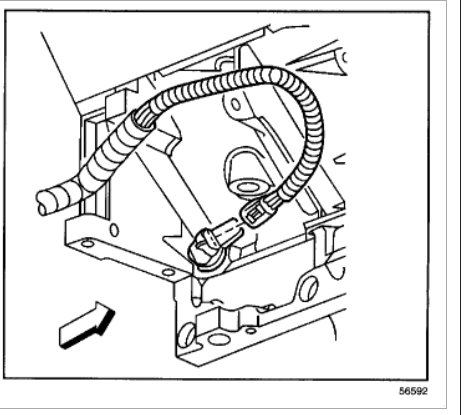

I have a 2004 trailblazer that had a blown head gasket. I purchase the Camshaft Holding Tool, I already had the angle meter and I purchased the tension-er holding tool to complete the job. Everything went well during the rebuild and I took my time. All the timing marks lined up, etc. I followed detailed instructions during the whole process and took my time. When I fired it up it did ok but I notice a rough idle but did not notice a loss of power. This rough idle go worse and now I get the P0016 code and some loss of power. I can clear the P0016 it and it comes back. I have a scan tool that gives me some data. Camshaft phase solenoid DC 0%, Cam Phase angle desired 0, Cam Phase angle Actual 0, cam phase angle variance 0, CMP and CKP active counters are showing changing data. I have replaced the actuator on the side of the engine and the exhaust cam sensor. When I pulled the old actuator I notice that the screen had some aluminum dust on the screen from where the head was milled down. I had tried to clean this from the head prior to installation but I guess I missed some. I went ahead and put in the new actuator. I have since pull the new actuator and the dust is gone. I have also changed the oil since. I have pinned out the wires from the actuator the PCM and they are good. I need some help and ideas. The question I have is concerning the operation and setting of the actuator sprocket. When following the instructions I was not sure how the advance the actuator on the exhaust sprocket when bolting it up to the cam. I tried to turn the front of the sprocket clockwise and it would not move. I didn’t want to force because I have read you can damage it. I need to know the details on how to advance the actuator on the sprocket so I can confirm if I’m doing it correctly or maybe mine is bad. I can say it would not rotate forward or backward. Also, the timing marks lined up on both sprockets correctly at TDC. Can the crank be off even with the two at the top dead on? The chain seem to be tensioned evenly.

Wednesday, May 15th, 2019 AT 12:40 PM

(Merged)