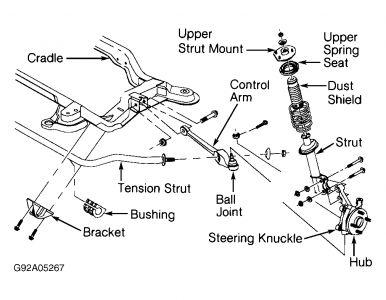

Recently I installed the lower control arms on my 97 Saturn SL1. When I put them on, I screwed the castle nut down all the way and installed the cotter pins. I noticed the next day the castle nuts had worked there way up and were touching the cotter pins. When this happens, the car seems kind of sluggish. If I tighten them down, the steering feels stiffer but the problem with that is every time I hit a bump the steering wheel jerks real hard.

Is the castle nut suppose to stay down all the way or do I screw them down just enough to slide the cotter pins through?

When there not screwed down all the way, the car is sluggish and acts like it wants to pull in either direction.

I need to ensure I have those installed correctly.

Any ideas what might be going on would be appreciated. Thanks.

SPONSORED LINKS

Sunday, February 28th, 2010 AT 7:36 PM