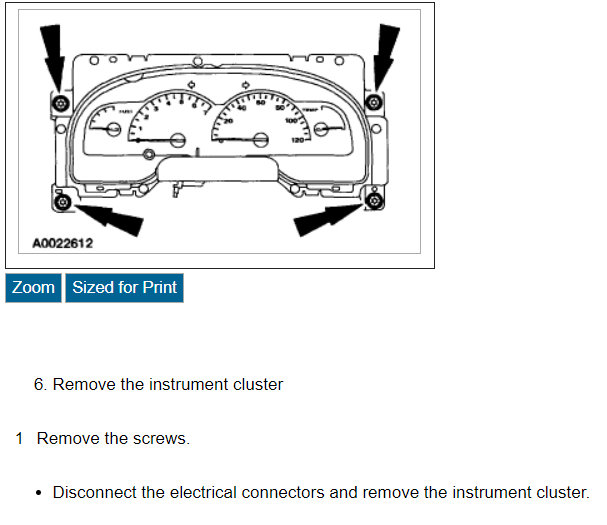

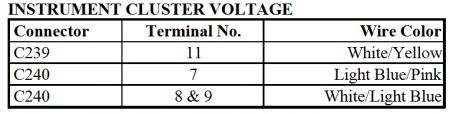

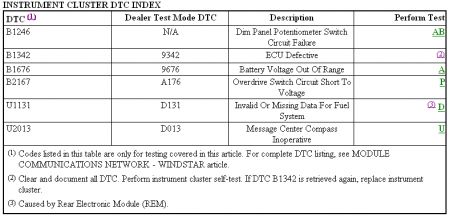

The dash gauges (speedometer, tachometer, temperature and gas) in my van have suddenly started going crazy crazy. I have owned it for two years and it had happened once or twice in that time. They would all "top out" and then quickly return to normal. I did not give it much thought after that. Recently they have started doing it constantly but now they will "stick" in different positions (i.E. 0, 40 or 120+ mph gas full, empty or half etc.) And they continue to bounce around. Usually the tachometer and speedometer together and the temperature and fuel together, sometimes all four. Can you please give me some indication where to start or am I looking at a more serious problem that I should not be doing myself?

SPONSORED LINKS

Thursday, July 9th, 2009 AT 9:20 AM