If there is no spark at the coil and there is power going to it, means the coil is bad.To prove that we need to check its resistance.

PRIMARY COIL WINDING RESISTANCE

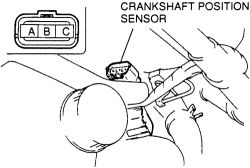

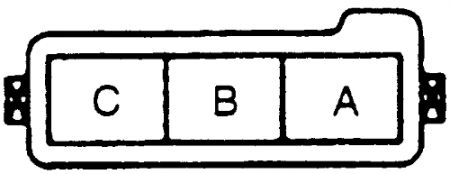

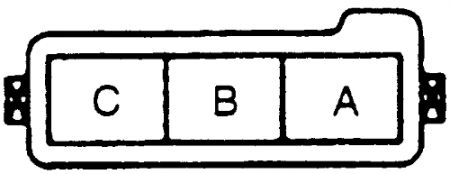

Detach the coil pack wire harness connector.

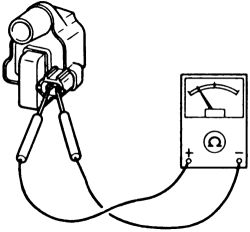

Connect an ohmmeter to terminals A and B and record the reading.

Connect an ohmmeter to terminals C and B and record the reading.

The resistance specification is 0.45-0.55 ohms

if any of the readings are not within specification, replace the coil pack.

SECONDARY COIL WIRE RESISTANCE

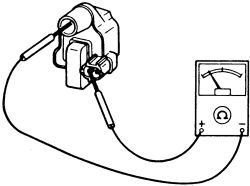

# Label and detach the spark plug wires from the coil pack.

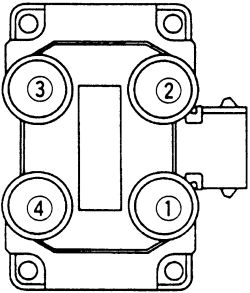

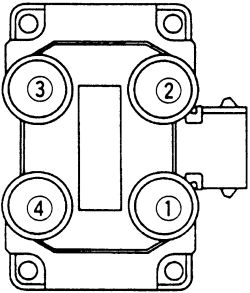

# On 2.0L engines, measure the resistance between the spark plug terminals as follows:

1. Connect an ohmmeter to terminals 1 and 4 and record the reading.

2. Connect an ohmmeter to terminals 2 and 3 and record the reading.

The resistance specification is 11.5-15.5k ohms

If any of the readings are not within specification, replace the coil pack

Friday, February 26th, 2010 AT 8:10 PM