Fuel module (7.4L, 5.7L G Van & 5.7L Over 8500 GVWR).

Fuel module overrides the ECM two second timer and fuel pump runs twenty seconds before shutting off when vehicle is not started. This added circuit corrects hot restart problems which could cause vapor lock during high ambient temperatures.

Fuel pump:

An in-tank electric fuel pump delivers fuel to injector(s) through an in-line fuel filter. The pump is designed to supply fuel pressure in excess of vehicle requirements. The pressure relief valve in the fuel pump controls maximum fuel pump pressure.

On TBI fuel systems, pressure regulator is mounted on throttle body. On port fuel injection (PFI) systems, pressure regulator is mounted on the fuel rail. Regulator keeps fuel available to injector(s) at a constant pressure. Excess fuel is returned to fuel tank through pressure regulator return line.

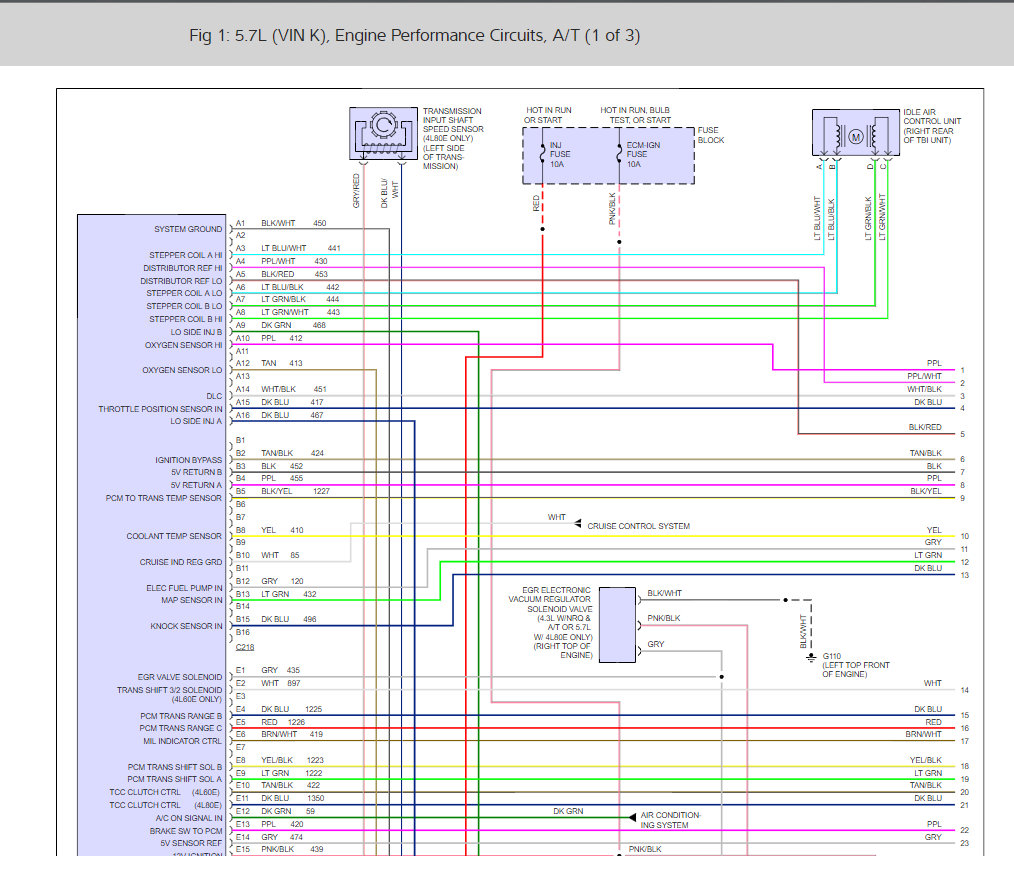

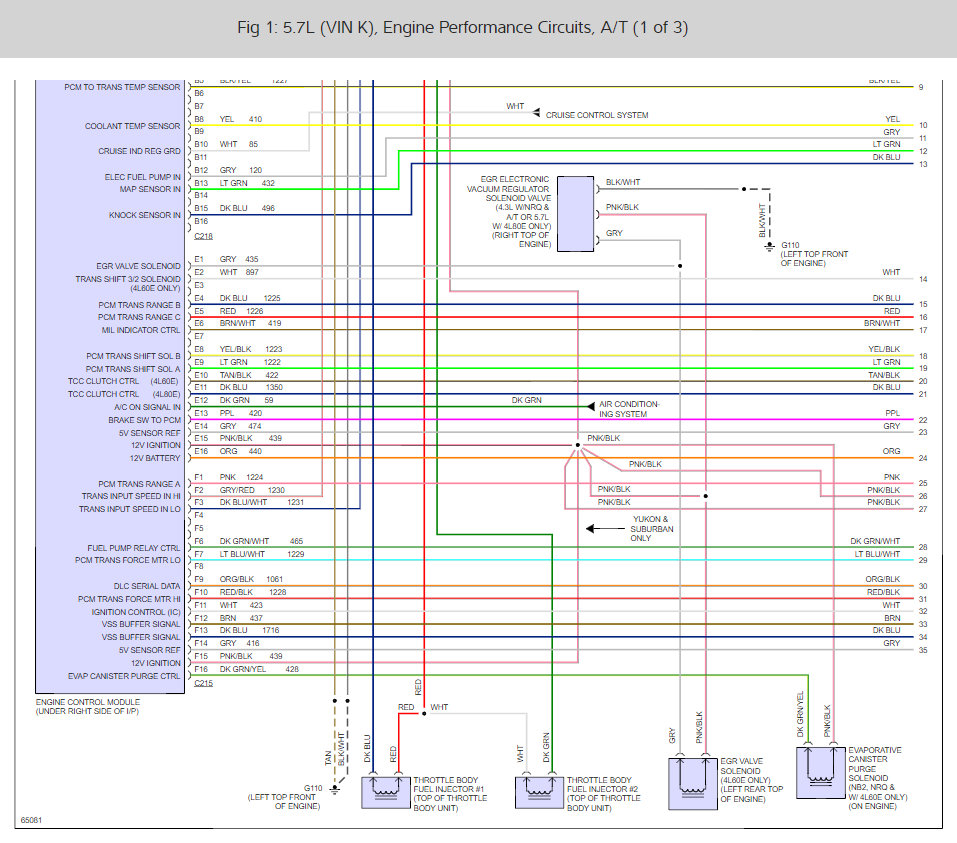

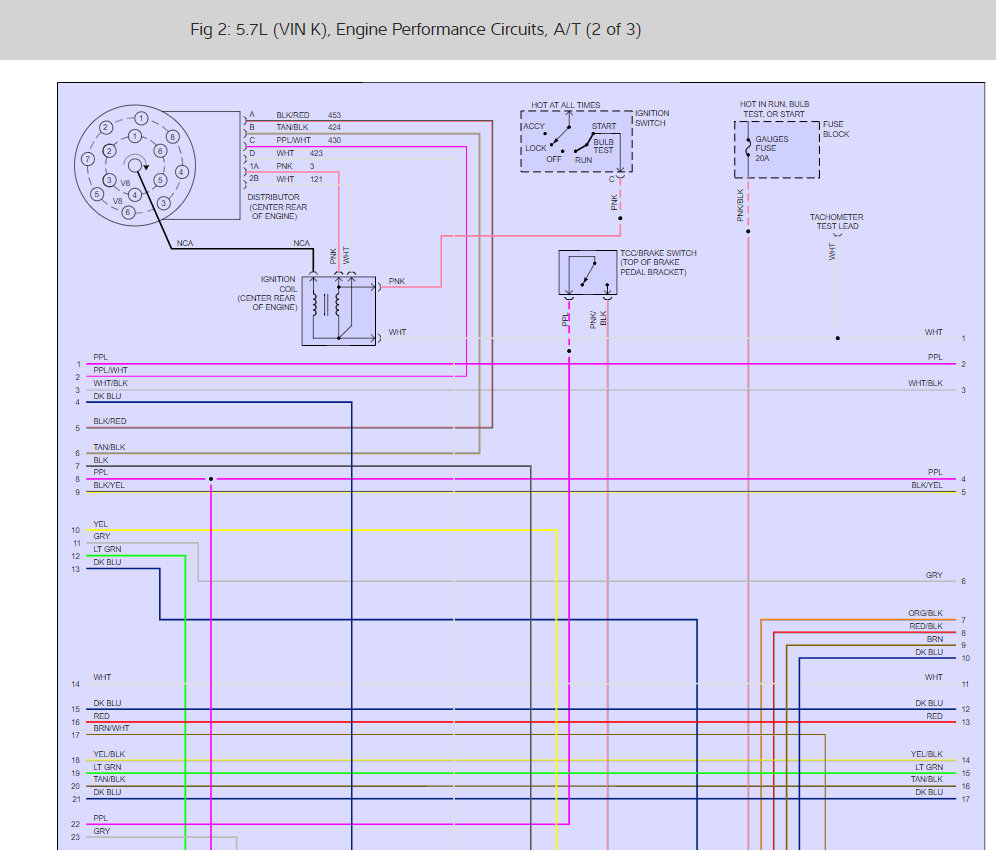

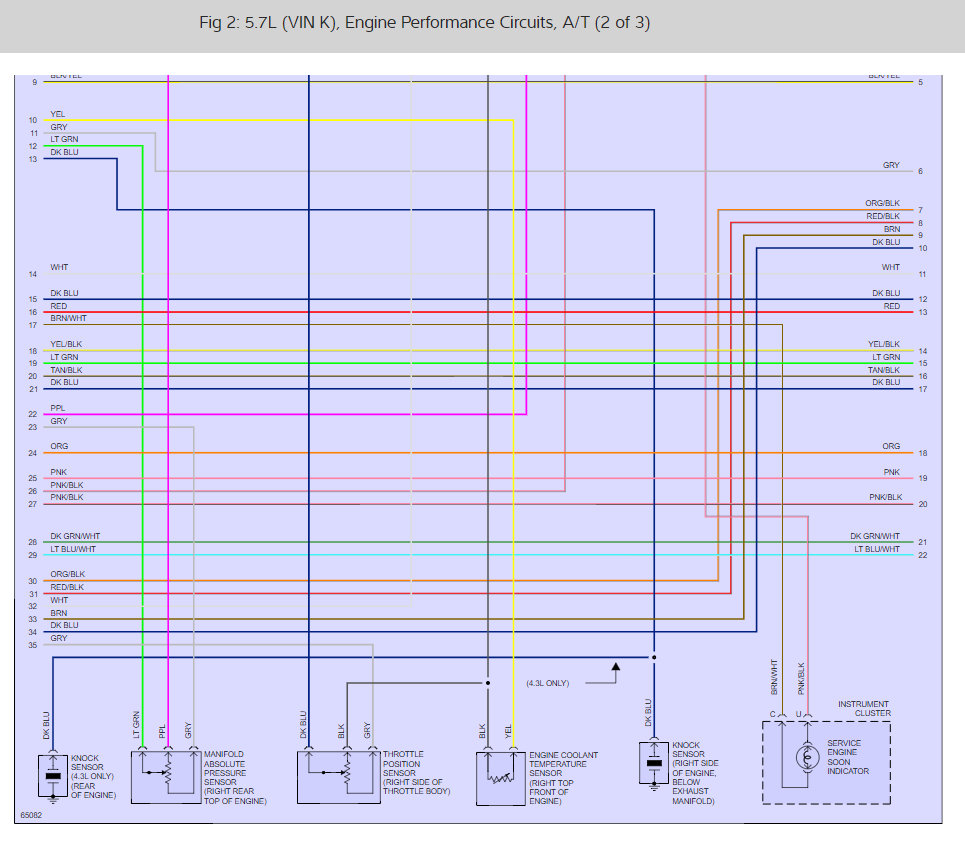

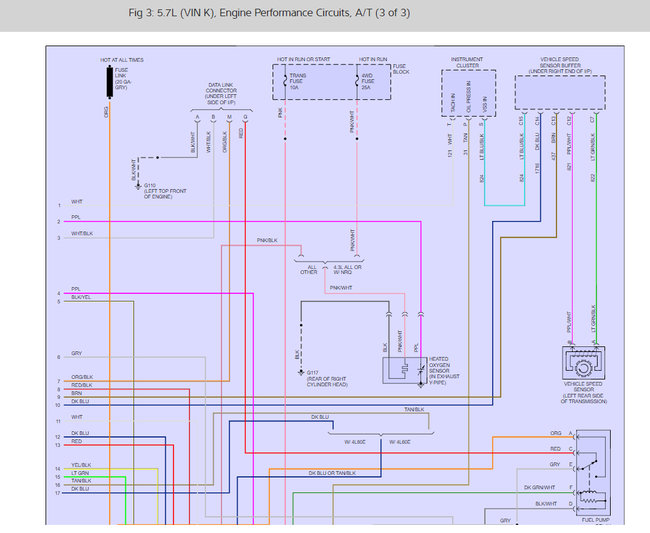

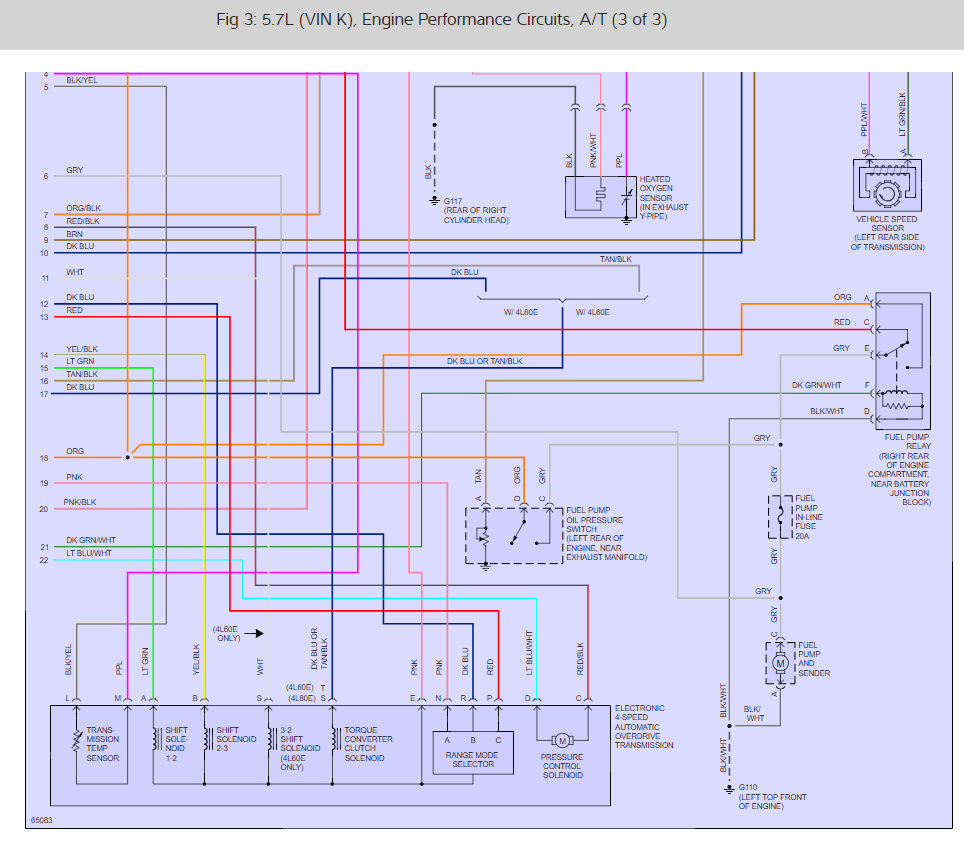

When ignition switch is turned to "on" position, ECM turns on electric fuel pump by energizing fuel pump relay. ECM keeps pump on if engine is running or cranking (ECM is receiving reference pulses from ignition module). If there are no reference pulses and vehicle is not equipped with a fuel module, ECM turns pump off within two seconds after ignition is turned on. For additional information, see Fuel pump relay and Fuel module under fuel delivery.

Fuel pressure regulator (CPI):

A constant fuel pressure of 54-64 psi (3.8-4.5 kg/cm2 ) is maintained by a factory preset, nonadjustable, spring loaded diaphragm contained within CPI assembly. Spring tension maintains a constant fuel pressure to injector regardless of engine load.

Fuel Pressure Regulator (TBI):

A constant fuel pressure of 9-13 psi (.6-9 kg/cm2 ) is maintained by a factory preset, nonadjustable, spring loaded diaphragm contained within throttle body. Spring tension maintains a constant fuel pressure to injector regardless of engine load.

Fuel Pressure Regulator (4.3L Turbo PFI)

Fuel pressure regulator is a diaphragm-operated relief valve with injector pressure on one side and manifold pressure (vacuum) on the other. Pressure regulator compensates for engine load by increasing fuel pressure when low manifold vacuum is experienced.

During periods of high manifold vacuum, regulator-to-fuel tank return orifice is fully open, keeping fuel

pressure on the low side of its regulated range. As throttle valve opens, vacuum to regulator diaphragm decreases, allowing spring tension to gradually close off return passage. At wide open throttle (when vacuum is at its lowest), return orifice is restricted, providing maximum fuel volume and maintaining constant fuel pressure to injectors.

Fuel pump relay:

When ignition switch is turned to ON position, ECM turns electric fuel pump on by energizing fuel pump relay. ECM keeps relay energized if engine is running or cranking (ECM is receiving reference pulses from ignition module). If there are no reference pulses, ECM turns pump off within two seconds after key on.

As a back-up system to fuel pump relay, the oil pressure switch also activates fuel pump. The oil pressure switch is normally open until oil pressure reaches approximately four psi (.28 kg/cm 2 ). If fuel pump relay fails, the oil pressure switch closes when oil pressure is obtained, and operates the fuel pump. An inoperative fuel pump relay may result in extended cranking times due to the time required to build up oil pressure. Oil pressure switch may be combined into a single unit with an oil pressure gauge sending unit or sensor.

ECM monitors fuel pump circuit between fuel pump relay/oil pressure switch and fuel pump, enabling ECM to determine if fuel pump is being energized by fuel pump relay or oil pressure switch. A failure in this monitored circuit results in the setting of a related trouble code in ECM memory.

Monday, October 6th, 2008 AT 2:29 PM