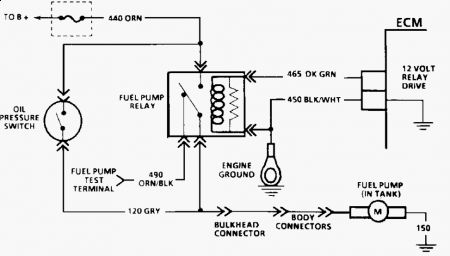

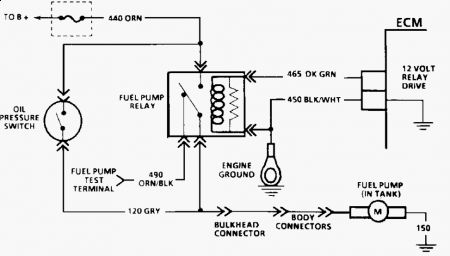

If the fuel system was OK before the trip to last chance gagage, I would test the ground and power wiers to the tank unit. They may have pinched, in my opinion the ground wire...crossed to power? Check the PCM and Fuel pump grounds as in this diagram.

Fuel Pump Relay (A-5)

Fuel Pump Relay By-Pass Procedure

Fig. 4: Typical Fuel Pump Relay Schematic Courtesy of GENERAL MOTORS CORP.

Oil Pressure Switch Fuel Pump Back-Up

With engine idling, disconnect fuel pump relay. Engine should continue to run through oil pressure switch back-up circuit. If engine stalls, check oil pressure switch and related wiring.

Page 1 of 1

1.Disconnect fuel pump relay connector. Refer to COMPONENT LOCATIONS at the end of this article to locate fuel pump relay. Apply battery voltage and ground to fuel pump relay winding terminals. To identify fuel pump relay terminals, see appropriate wiring diagram at the end of this article. 2.Using an ohmmeter, check for continuity between fuel pump relay power supply terminal and fuel pump drive terminal. Continuity should exist ONLY with relay energized. If relay does not test as indicated, replace relay. 3.To by-pass fuel pump relay (to test fuel pump and wiring when fuel pump is not energizing), see FUEL PUMP RELAY BY-PASS PROCEDURE below.

1.If fuel pump will not energize, relay may be by-passed to test fuel pump and related wiring. See Fig. 4 . Turn ignition off. Disconnect fuel pump relay connector. Using a fused jumper wire, apply battery voltage to fuel pump test connector (located in engine compartment). For fuel pump test connector location, refer to COMPONENT LOCATIONS at end of this article. See Fig. 53 - Fig. 55 . 2.If fuel pump runs and relay tests okay, check for faulty connections at relay. If fuel pump does not run, check for faulty wiring between relay and fuel pump or replace defective fuel pump.

Also test injectors, with an ohm meter, test warm, reading should be 12.0-12.4 ohms, Replace ANY NOT IN SPEC, MOST TECHS RECOMMEND CHANGING ALL AT THE SAME TIME..

Sunday, February 28th, 2010 AT 3:59 PM