I used my ODB II Scanner and there are no codes, however when I check the “I/M" status I get O2S Not RDY, HO2S Not RDY, and EGR Not RDY.

I verified that I have 12Volts to the Fuse Panel next to the ECM. Traced every wire and found each wire connected. I did have to crimp a new ground connector near the lefts side of the water inlet on the intake.

Any thoughts?

I do have spark at the plugs, I also noticed that the tach nor any of the other guages appear to be working. I woudl think it aws the ECM causing the problem. However I had the truck running before I took it apart.

There is an aftermarket remote starter on the truck. Not sure if this woul dhave anything to do with it or not but nothing was touched other than pulling the engine for a rebuild.

6/7/10 Update:

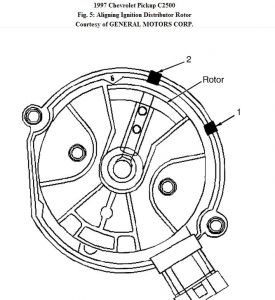

I verified TDC today. I still think the root problem will be solved once I find what would cause the dash lights from coming on when the ignition is in the ON position. Does anyone know what would cause the lights and the guages not to respond when you turn the key on?

SPONSORED LINKS

Saturday, June 5th, 2010 AT 12:13 PM