Using¬ scan¬ tool, ¬ read¬ FREEZE¬ FRAME¬ data.¬ Freeze¬ frame¬ data¬ records¬ engine¬ conditions¬ when¬ malfunction¬ is¬ detected.

Diagnosis¬ &¬ Repair

1. Check¬ for¬ spark¬ at¬ misfiring¬ cylinder.¬ See¬ IGNITION¬ SYSTEMS¬ in¬ BASIC¬ DIAGNOSTIC¬ PROCEDURES ¬ 4 CYLINDER¬ article.¬ If¬ spark¬ exists, ¬ go¬ to¬ next¬ step.¬ If¬ spark¬ does¬ not¬ exist, ¬ go¬ to¬ step 4.

2. Check¬ for¬ open¬ or¬ short¬ in¬ Blue/Yellow¬ wire¬ between¬ ECM¬ and¬ ignition¬ coil/ignitor¬ No.¬ 3.¬ Also, ¬ check¬ for¬ open¬ or¬ short¬ in¬ Gray¬ wire¬ between¬ ECM¬ and¬ ignition¬ coil/ignitor¬ No.¬ 3.¬ See¬ WIRING¬ DIAGRAMS

article.¬ If¬ problem¬ exists, ¬ repair¬ wiring¬ as¬ necessary.¬ If¬ problem¬ does¬ not¬ exist, ¬ go¬ to¬ next¬ step.

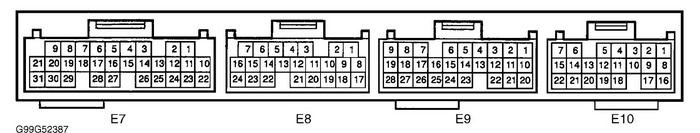

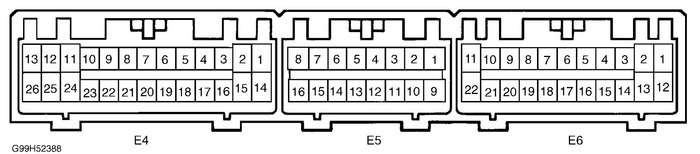

3. Disconnect¬ ignition¬ coil/ignitor¬ No.¬ 3¬ harness¬ connector.¬ Access¬ ECM¬ below¬ stereo, ¬ behind¬ instrument¬ panel, ¬ just¬ in¬ front¬ of¬ center¬ console.¬ See Fig.¬ 2.¬ Turn¬ ignition¬ on.¬ Using¬ DVOM, ¬ backprobe¬ at¬ ECM

harness¬ connector.¬ On¬ models¬ with¬ 4A/T¬ transmission, ¬ measure¬ voltage¬ between¬ ground¬ and¬ terminal¬ No.¬ 25¬ (Blue/Yellow¬ wire)¬ at¬ ECM¬ harness¬ connector¬ E7.¬ See Fig.¬ 4.¬ On¬ models¬ without¬ 4A/T¬ transmission,

measure¬ voltage¬ between¬ ground¬ and¬ terminal¬ No.¬ 3¬ (Blue/Yellow¬ wire)¬ at¬ ECM¬ harness¬ connector¬ E4.¬ See Fig.¬ 5.¬ On¬ all¬ models, ¬ voltage¬ should¬ be¬ 4.5 5.5¬ volts.¬ If¬ voltage¬ is¬ as¬ specified, ¬ replace¬ ignition

coil/ignitor¬ No.¬ 3.¬ If¬ voltage¬ is¬ not¬ as¬ specified, ¬ replace¬ ECM.

4. Check¬ for¬ open¬ or¬ short¬ in¬ Gray¬ wire¬ between¬ ECM¬ and¬ ignition¬ coil/ignitor¬ No.¬ 3.¬ See¬ WIRING¬ DIAGRAMS¬ article.¬ If¬ problem¬ exists, ¬ repair¬ wiring¬ as¬ necessary.¬ If¬ problem¬ does¬ not¬ exist, ¬ go¬ to¬ next¬ step.

5. Access¬ ECM¬ below¬ stereo, ¬ behind¬ instrument¬ panel, ¬ just¬ in¬ front¬ of¬ center¬ console.¬ See Fig.¬ 2.¬ Using¬ DVOM, ¬ backprobe¬ ECM¬ harness¬ connector.¬ On¬ models¬ with¬ 4A/T¬ transmission, ¬ measure¬ voltage¬ between

ground¬ and¬ terminal¬ No.¬ 12¬ (Gray¬ wire)¬ at¬ ECM¬ harness¬ connector¬ E7¬ while¬ cranking¬ engine.¬ See Fig.¬ 4.¬ On¬ models¬ without¬ 4A/T¬ transmission, ¬ measure¬ voltage¬ between¬ ground¬ and¬ terminal¬ No.¬ 22¬ (Gray¬ wire)

at¬ ECM¬ harness¬ connector¬ E4¬ while¬ cranking¬ engine.¬ See Fig.¬ 5.¬ On¬ all¬ models, ¬ voltage¬ should¬ be¬.1 4.5¬ volts.¬ If¬ voltage¬ is¬ not¬ as¬ specified, ¬ go¬ to¬ next¬ step.¬ If¬ voltage¬ is¬ as¬ specified, ¬ go¬ to¬ step 7.

6. Disconnect¬ ignition¬ coil/ignitor¬ No.¬ 3¬ harness¬ connector.¬ Using¬ DVOM, ¬ backprobe¬ ECM¬ harness¬ connector.¬ On¬ models¬ with¬ 4A/T¬ transmission, ¬ measure¬ voltage¬ between¬ ground¬ and¬ terminal¬ No.¬ 12¬ (Gray¬ wire)

at¬ ECM¬ harness¬ connector¬ E7¬ while¬ cranking¬ engine.¬ On¬ models¬ without¬ 4A/T¬ transmission, ¬ measure¬ voltage¬ between¬ ground¬ and¬ terminal¬ No.¬ 22¬ (Gray¬ wire)¬ at¬ ECM¬ harness¬ connector¬ E4¬ while¬ cranking

Images (Click to make bigger)

Tuesday, January 10th, 2012 AT 5:37 PM