With the questions you are asking, I believe you do not have sufficient information nor the experience to do it and if I were you, I would not be doing this job.

Anyway these are the procedures from our database. Hope they are helpful.

REMOVAL & INSTALLATION

TIMING BELT

CAUTION:

This application is an interference engine. Do not rotate camshaft or crankshaft when timing belt is removed, or engine damage may occur.

Removal

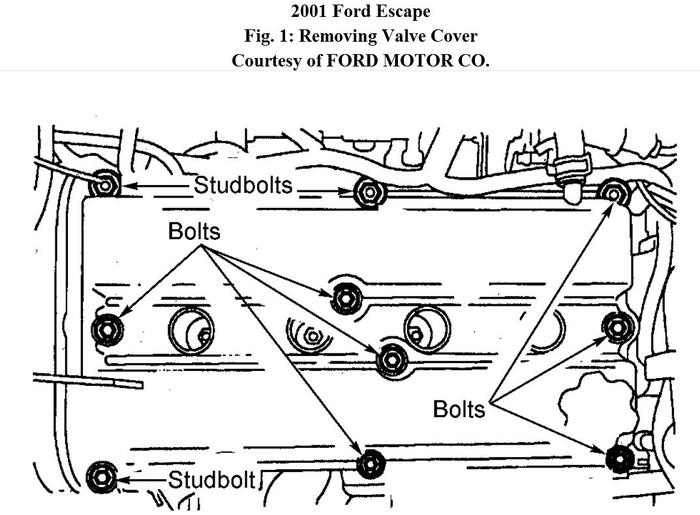

1. Disconnect negative battery cable. Remove accessory drive belt. Remove air cleaner outlet pipe. Disconnect ignition wires from spark plugs. Remove spark plugs. Disconnect throttle cable and cruise control actuator cable. On 2002-04 models, disconnect the catalyst monitor and heated oxygen sensor connectors, and detach the connectors from the bracket. Remove wiring harness anchors from valve cover studs, and position the wiring harness aside. On all models, remove valve cover. See Fig. 1.

2. Remove catalytic converter. Remove coolant tube bolt and nut. Position coolant tube to side. Remove right front wheel and tire assembly. Remove right lower splash shield.

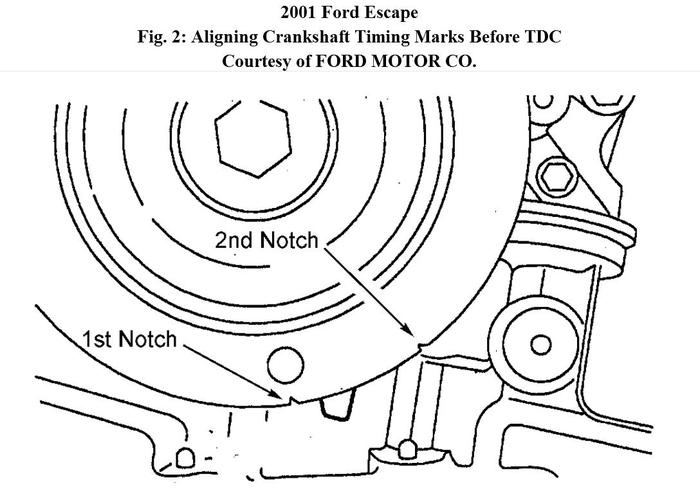

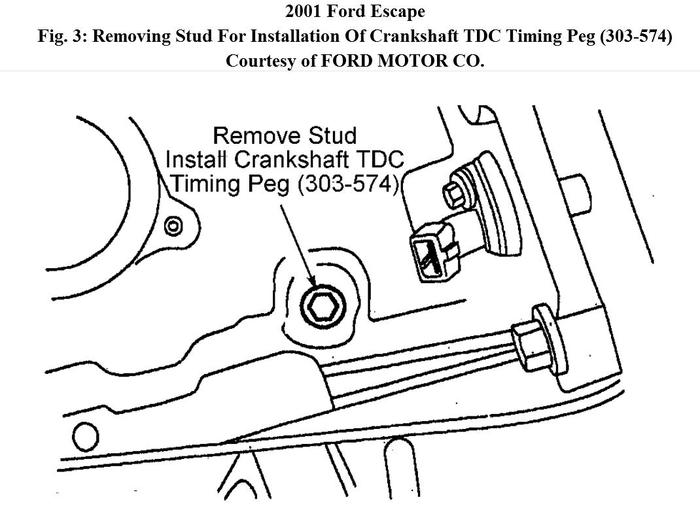

3. Rotate crankshaft to just before No. 1 cylinder TDC. See Fig. 2. Remove stud and install Crankshaft TDC Timing Peg (303-574). See Fig. 3.

NOTE:

Make sure second notch in pulley is indexed to lower cylinder block. See Fig. 2.

4. Rotate crankshaft clockwise against peg to bring it to TDC. Loosen water pump pulley bolts.

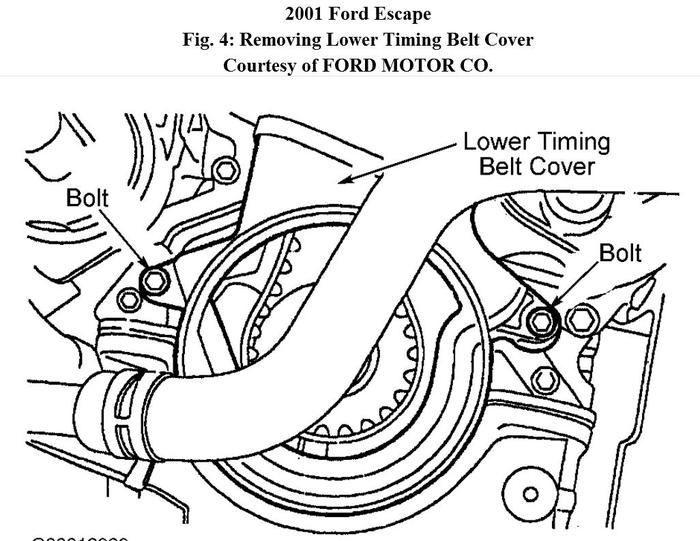

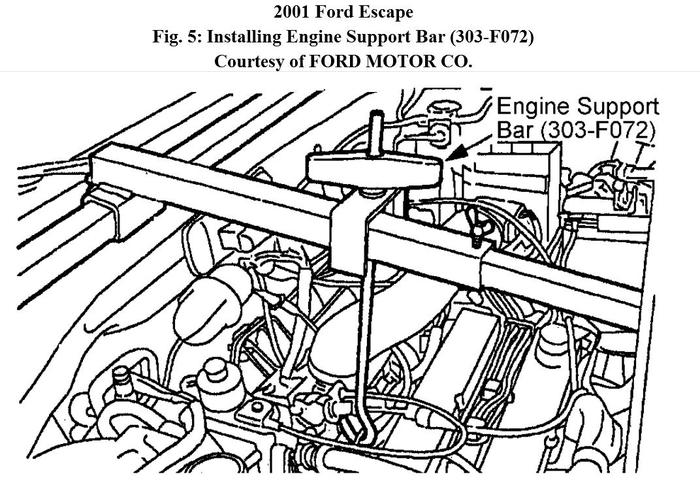

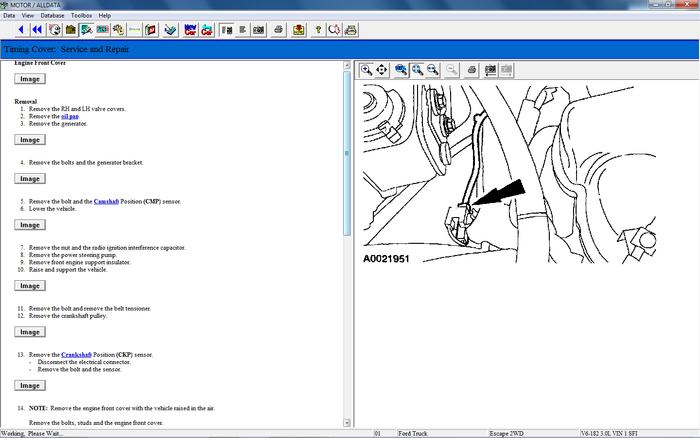

5. Loosen crankshaft pulley bolt. Rotate tensioner and remove accessory drive belt. Remove crankshaft pulley. Remove bolts and lower timing belt cover. See Fig. 4. Install Engine Support Bar (303-F072). See Fig. 5.

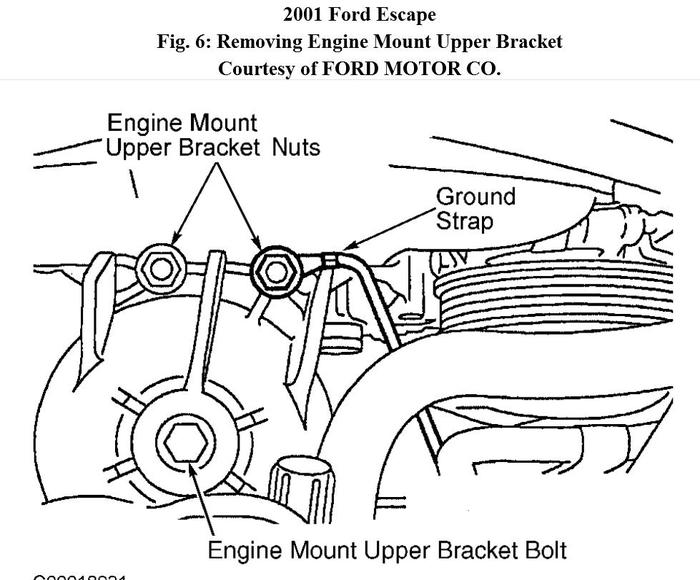

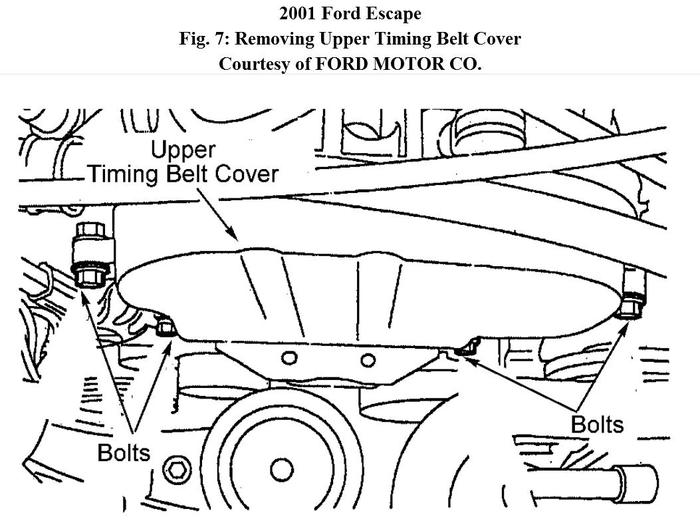

6. Remove ground strap and engine mount upper bracket. See Fig. 6. Remove upper timing belt cover studs. Disconnect the knock sensor connector from upper timing cover, if necessary. Remove upper timing belt cover bolts and cover. See Fig. 7.

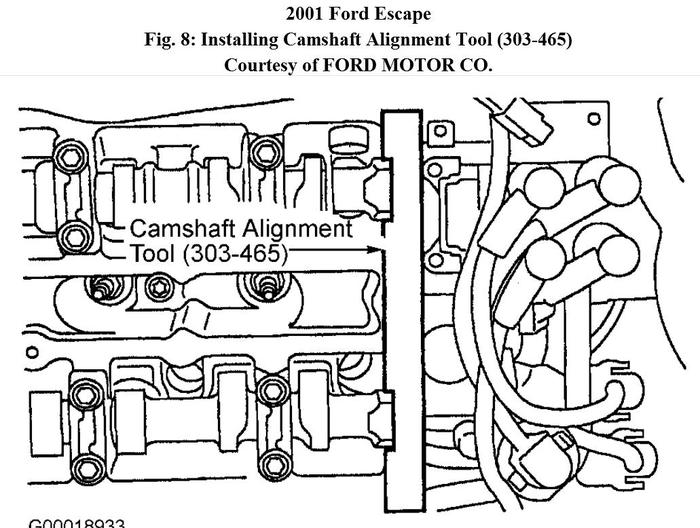

NOTE:

Installation of Camshaft Alignment Tool (303-465) into exhaust camshaft may require camshafts to be rotated slightly clockwise.

7. Remove water pump pulley and accessory drive belt idler pulley. Install Camshaft Alignment Tool (303-465) and align camshafts. See

Fig. 8.

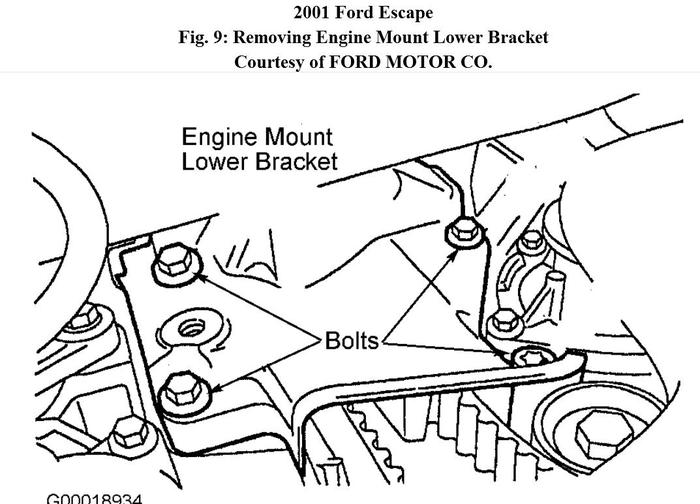

8. Raise and support vehicle. Remove engine mount lower bracket. See

Fig. 9.

9. Loosen timing belt tensioner pulley, and allow it to slide down to bottom of its travel. If timing belt is going to be reused, mark direction of rotation for installation reference. Slide timing belt off of camshaft and crankshaft sprockets.

Installation

1. Slide crankshaft pulley onto crankshaft. Ensure crankshaft position is at No. 1 TDC by rotating it clockwise against Crankshaft TDC Timing Peg (303-574). Ensure second notch in pulley is indexed to lower cylinder block. See Fig. 2. Remove crankshaft pulley.

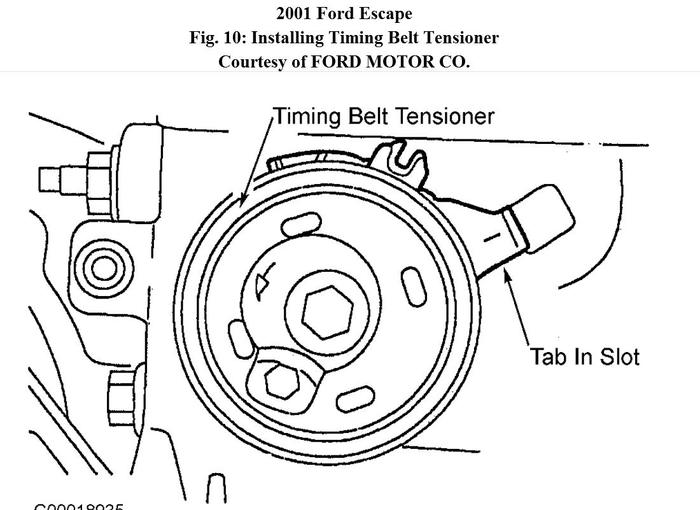

2. Ensure timing belt tensioner is installed correctly with tab positioned in slot in inner timing cover. See Fig. 10.

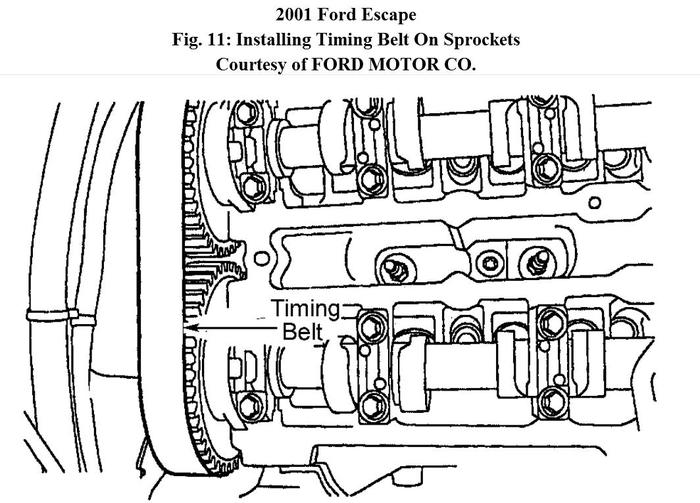

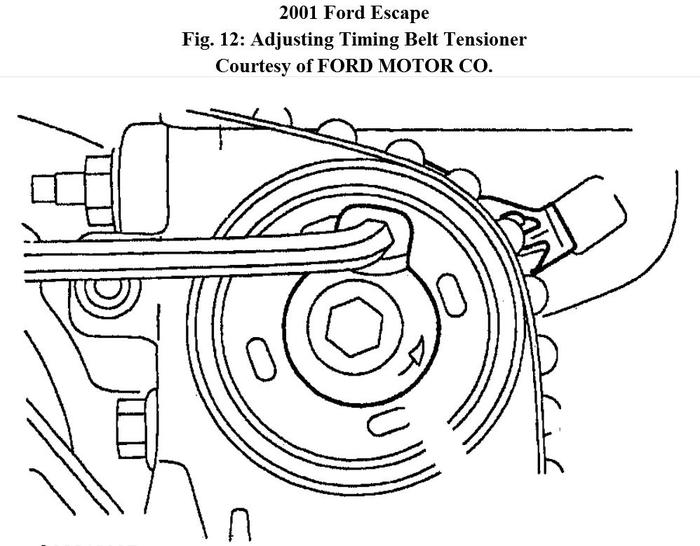

3. Starting from the crankshaft timing belt pulley and working counterclockwise, position the timing belt in place while keeping it under tension. Adjust timing belt tensioner by using a 6-mm Allen wrench to rotate adjuster counterclockwise and align marks. See

Fig. 11 and Fig. 12. Tighten tensioner pulley bolt to

specification.

4. Install front engine mount lower bracket. Install accessory drive belt idler pulley. Install water pump pulley, and hand tighten bolts. Install timing belt covers. Install crankshaft pulley. Tighten water pump pulley bolts to specification.

5. Install splash shield, then wheel and tire assembly. Remove Crankshaft TDC Timing Peg (303-574). Install stud. Install engine mount upper bracket and ground strap. Remove Engine Support Bar (303-F072). Install coolant tube and catalytic converter. Remove Camshaft Alignment Tool (303-465).

6. Install valve cover and spark plugs. On 2002-04 models, connect wiring harness anchors to valve cover studs. Install and reconnect the catalyst monitor and heated oxygen sensor connectors. On all models, reconnect accelerator cable and cruise control actuator cable. Install ignition wires, air cleaner outlet pipe and

accessory drive belt. Reconnect negative battery cable.

Images (Click to make bigger)

Tuesday, September 4th, 2012 AT 12:55 PM